Preparation method for photocatalysis composite material made from graphite oxide and carbon nitride

A technology of composite materials and carbon nitride, which is applied in the field of preparation of photocatalytic composite materials, can solve the problems of poor dispersion of carbon nitride, time-consuming sonochemical method, unsuitable for large-scale application, etc., achieving low cost and suitable for large-scale The effect of simple production and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

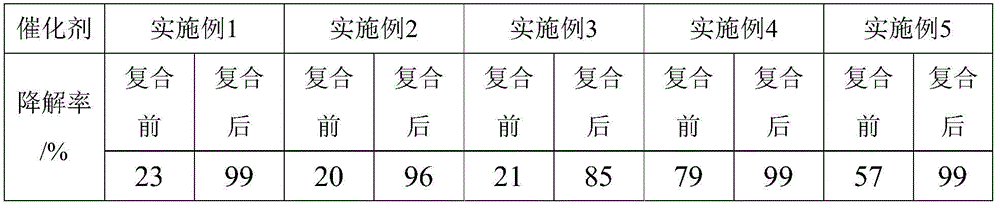

Examples

Embodiment 1

[0017] (1) At room temperature, put 5 g of cyanamide in a crucible with a lid, heat it to a temperature of 450° C. in an air atmosphere in a horse-boiler furnace for 6 hours, and the heating rate is 5° C. / min. After cooling, a yellow solid powder is obtained. carbon nitride;

[0018] (2) Disperse 1.5 g of carbon nitride obtained in step (1) in 10 mL of sulfuric acid with a mass concentration of 98%, stir for 1 hour, centrifuge, wash the resulting solid, and dry to obtain acidified carbon nitride;

[0019] (3) Disperse 100 mg of the acidified carbon nitride obtained in step (2) in 10 mL of deionized water, and disperse it ultrasonically for 30 minutes; then add 1 mL of graphite oxide aqueous solution with a concentration of 1 mg / mL under stirring to produce a gray precipitate, and stop stirring , ultrasonically dispersed for 30 minutes; after the obtained precipitate was filtered and dried, a photocatalytic composite material of graphite oxide and carbon nitride with a mass rat...

Embodiment 2

[0021] (1) At room temperature, place 5g of dicyandiamide in a tube furnace, heat it to a temperature of 500°C for 4 hours in a nitrogen atmosphere at a heating rate of 5°C / min, and obtain yellow solid powder nitrogen after cooling. carbonization;

[0022] (2) Disperse 1 gram of carbon nitride obtained in step (1) in 10 mL of sulfuric acid with a mass concentration of 80%, stir for 2 hours, centrifuge, wash the resulting solid, and dry to obtain acidified carbon nitride;

[0023] (3) Disperse 100 mg of the acidified carbonitride obtained in step (2) in 20 mL of deionized water, and disperse ultrasonically for 30 minutes; then add 5 mL of graphite oxide aqueous solution with a concentration of 1 mg / mL under stirring to produce a gray precipitate, and stop stirring , ultrasonically dispersed for 30 minutes; after the obtained precipitate was filtered and dried, a photocatalytic composite material of graphite oxide and carbon nitride with a mass ratio of graphite oxide and carbon...

Embodiment 3

[0025] (1) At room temperature, put 5 g of melamine in a crucible with a lid, heat it to a temperature of 650° C. in a muffle furnace under an argon atmosphere and bake it for 1 hour at a heating rate of 5° C. / min. After cooling, a yellow solid powder is obtained carbon nitride;

[0026] (2) Disperse 0.2 g of carbon nitride obtained in step (1) in 10 mL of sulfuric acid with a mass concentration of 10%, stir for 5 hours, centrifuge, wash the resulting solid, and dry to obtain acidified carbon nitride;

[0027] (3) Disperse 100 mg of the acidified carbon nitride obtained in step (2) in 50 mL of deionized water, and disperse it ultrasonically for 30 minutes; then add 50 mL of graphite oxide aqueous solution with a concentration of 1 mg / mL under stirring to produce a gray precipitate, and stop stirring , ultrasonically dispersed for 30 minutes; after the obtained precipitate was filtered and dried, a photocatalytic composite material of graphite oxide and carbon nitride with a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com