Manufacturing method of film polarizing plate, and film polarizing plate and polarizing plate manufactured using the method

A thin-film polarizer and a manufacturing method technology, applied to the manufacture of thin-film polarizers, can solve problems such as difficulties in achieving uniform physical properties of polyvinyl alcohol films, and achieve the effect of reducing the incidence of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] Hereinafter, according to an exemplary embodiment of the present invention, a method of manufacturing a thin film polarizing plate will be described in further detail.

[0036] First, a non-oriented polyvinyl alcohol-based film is bonded to and sandwiched between two or more non-oriented polymer films by attraction force or an adhesive layer to form a film laminate.

[0037] According to an exemplary embodiment of the present invention, the film laminate can be used as long as it has a structure in which a non-oriented polyvinyl alcohol-based film is arranged between two or more non-oriented polymer films, and the non-oriented The number of polymer films or the number of the non-oriented polyvinyl alcohol-based films is not particularly limited.

[0038] For example, the film laminate may have a film comprising a first non-oriented polymer film, a first non-oriented polyvinyl alcohol-based film bonded to the first non-oriented polymer film, and a first non-oriented poly...

Embodiment approach 1

[0104] Three sheets of non-oriented polyurethane film and two sheets of non-oriented polyvinyl alcohol-based film were alternately stacked on each other without using a dielectric material to form a film with non-oriented polyurethane film / non-oriented polyvinyl alcohol-based film / non-oriented polyurethane Film / Non-Oriented Polyvinyl Alcohol-Based Film / Non-Oriented Polyurethane Film Structure Film Laminate.

[0105] In this case, as the non-oriented polyvinyl alcohol-based film, Kuraray's PE30-grade polyvinyl alcohol-based film (thickness: 30 μm) can be used, and it is swelled in a pure solution at 25°C for 15 seconds, and then after using The iodine solution at a concentration of 0.3 wt % was subjected to a dyeing process at a temperature of 25° C. for 60 seconds.

[0106] A film manufactured using a thermoplastic polyurethane resin obtained by the mutual reaction of methylene diphenyl diisocyanate, 1,4-butanediol, and adipic acid may be used as the non-oriented polyurethane ...

experiment Embodiment 1

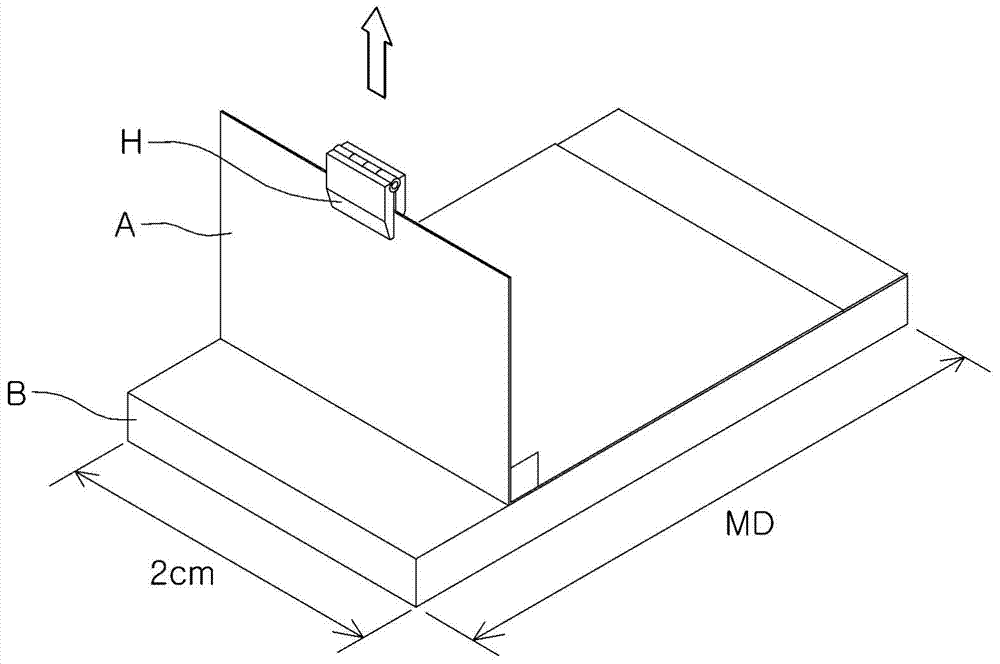

[0113] Experimental Example 1—Measurement of Breakage Incidence Rate

[0114] The film laminate of Embodiment 1 and Comparative Examples 1 and 2, and the polyvinyl alcohol-based film of Comparative Example 3 were subjected to a cleaning treatment for 15 seconds in a solution having 1 wt% of boron, and then cleaned in at least one The film laminate was oriented at an orientation magnification of 6 to 8 times just before breakage occurred on the polyvinyl alcohol-based film.

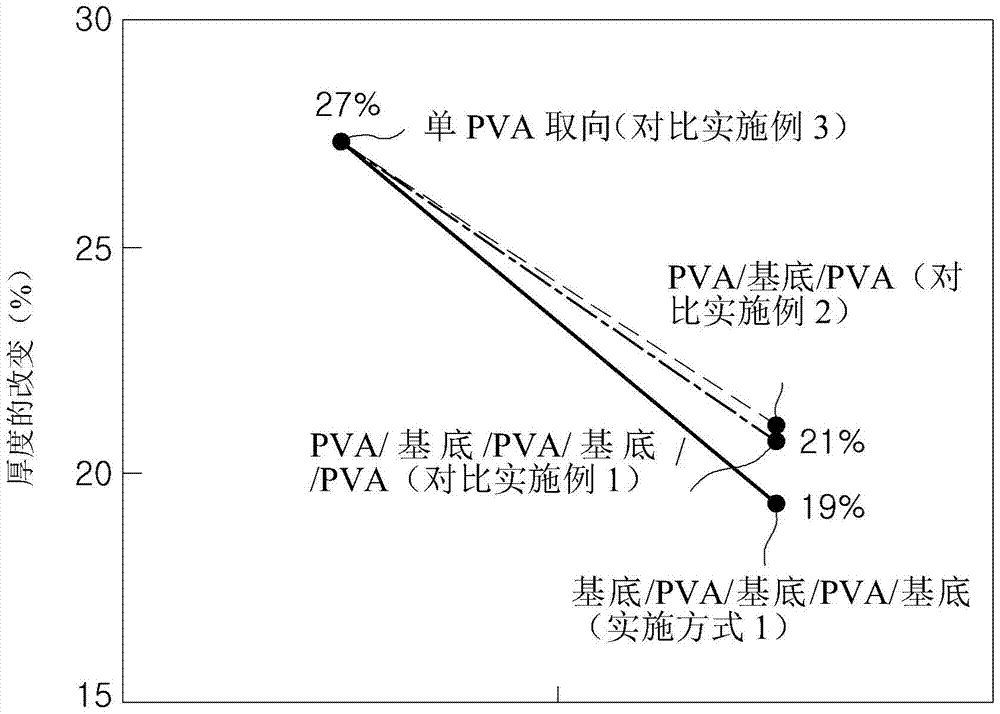

[0115] A ratio of the thickness of the polyvinyl alcohol-based film after the orientation process to the thickness of the polyvinyl alcohol-based film before the orientation process was calculated by the following formula. Its calculation result is in figure 2 Indicated.

[0116] Thickness ratio (dr) (%)={thickness of polyvinyl alcohol-based film after orientation (d) / thickness of polyvinyl alcohol-based film before orientation (do)}×100

[0117] The lower the value of the thickness ratio (dr), the ori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com