Experimental method for measuring high-temperature mechanical-chemical coupling of material by utilizing nanoindentor

A technology of nano-indentation instrument and experimental method, which is applied in the direction of testing material hardness, nanotechnology, and preparation of test samples, etc., which can solve the problems of limited oxidation mechanism and difficulty in investigating the oxidation behavior of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

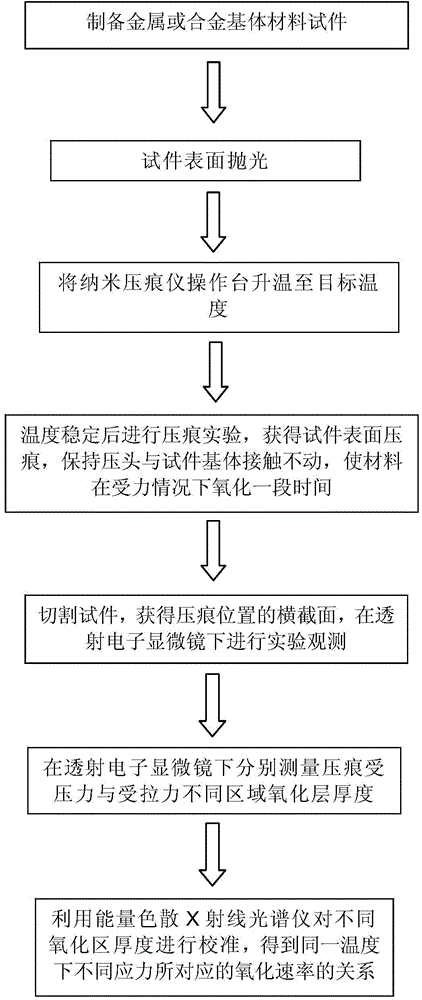

[0027] a. Prepare a nickel-based alloy material test piece, and grind and polish the surface of the test piece to meet the standard of high-temperature nano-indentation test on the surface finish of the test piece;

[0028] b. Heat up the operating table of the nanoindenter to 600°C; the determination of the temperature is based on several explorations in the experiment. Experiments were carried out at 400°C, 600°C and 800°C, and finally it was found that 600°C is more suitable for research The temperature of the oxidation behavior of Ni-based superalloys under different stress states;

[0029] c. After the temperature reaches 600°C, use the Berkovich indenter of the nano-indenter to perform an indentation experiment on the surface of the specimen at 11000 μN. After obtaining the indentation on the surface of the specimen, keep the indenter in contact with the substrate of the specimen for 60 minutes. Oxidize the material under stress;

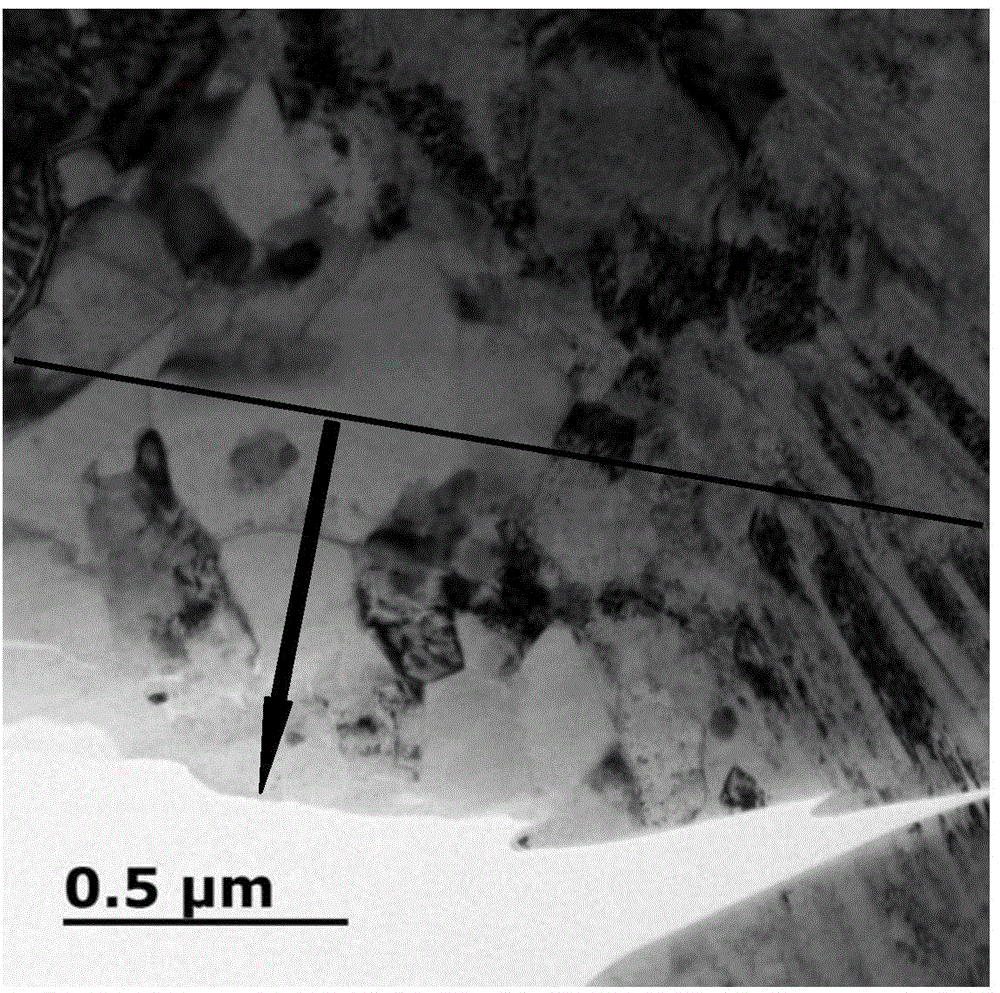

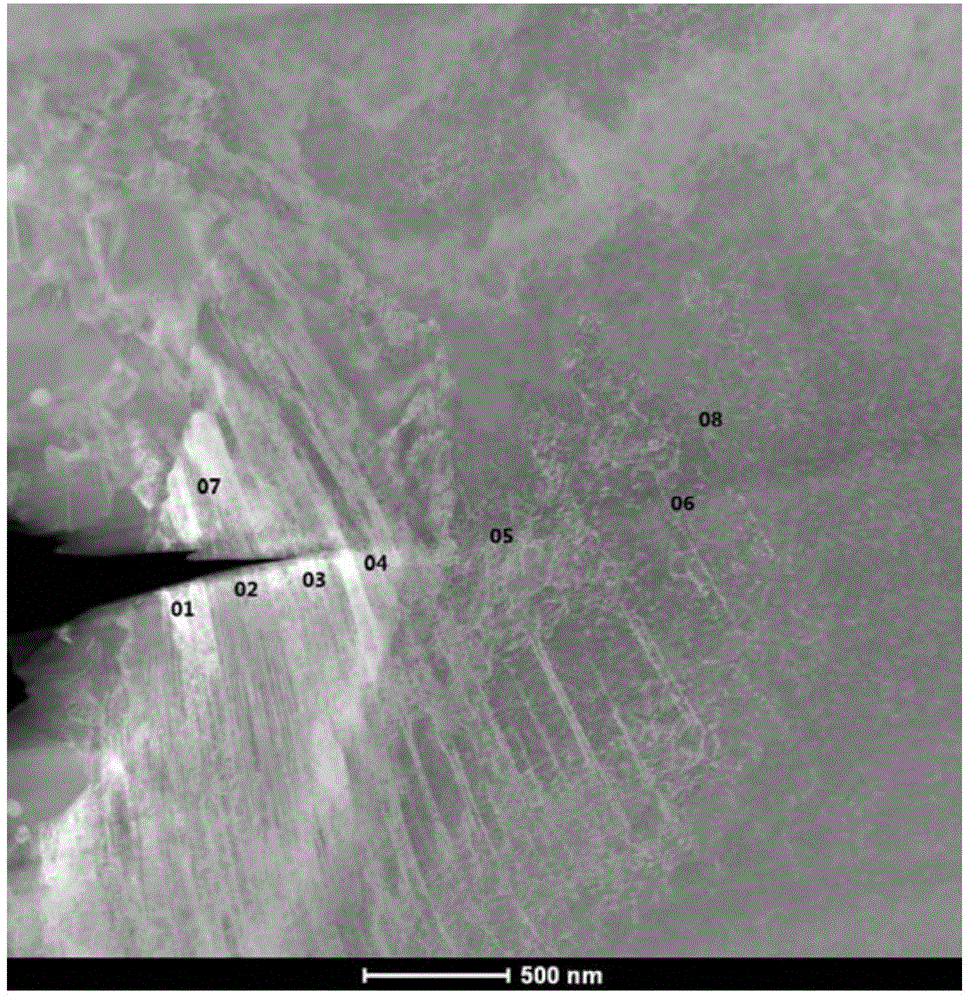

[0030] d. Cut the test piece, obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com