High-strength and high-durability lightweight aggregate concrete and preparation method thereof

A lightweight aggregate concrete and durability technology, applied in the field of lightweight aggregate concrete, can solve problems such as the inability to meet the service life, and achieve the effects of improving the resistance to chloride ion penetration of the structure, improving the workability of concrete, and increasing the span of large bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

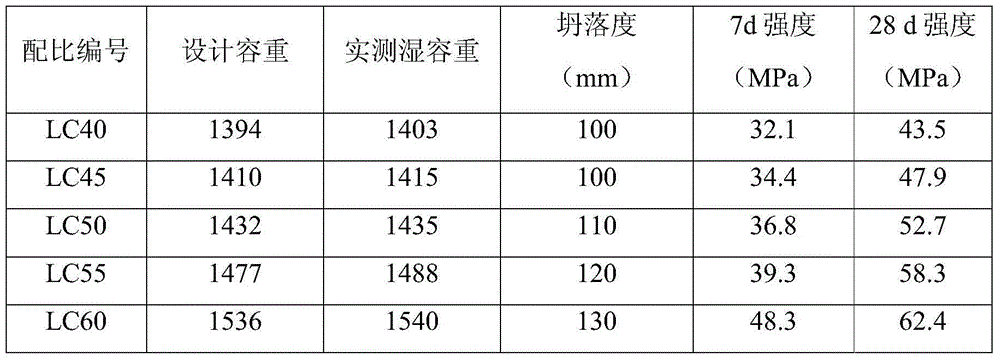

Embodiment 1

[0027] A kind of C40 high-strength and high-durability lightweight aggregate concrete and its preparation method:

[0028] The main raw materials in each m3 volume of concrete are as follows: Ordinary Portland cement P.O52.5R 250kg / m3 produced by Jidong Cement; micro-silica fume 150kg / m3; / m3; 240kg / m3 of mixing water in line with the industry standard JGJ 63-2006 "Water for Concrete"; 4kg / m3 of polycarboxylate high-efficiency water reducer produced by BASF, Germany.

[0029] Among them, the density of ordinary Portland cement P.O 52.5R cement is 3.09g / cm3, the initial setting time is 1.5h, the final setting time is 5.0h, the 7d compressive strength is 38.1MPa, and the 28d compressive strength is 57.4MPa. The silicon dioxide content of micro-silica powder is 90%, the specific surface area is 23m2 / g, and the pH value is 7.1; the lightweight ceramsite adopts crushed stone ceramsite produced in Zigui, Hubei Province, with a particle size of 5-15mm and an apparent The density is ...

Embodiment 2

[0032] A kind of C45 high-strength and high-durability lightweight aggregate concrete and its preparation method:

[0033] The main raw materials in each m3 volume of concrete are as follows: Ordinary Portland cement P.O52.5R 316kg / m3 produced by Jidong Cement Factory; micro-silica fume 160kg / m3; / m3; 200kg / m3 of mixing water in line with the industry standard JGJ 63-2006 "Water for Concrete"; 5.71kg / m3 of polycarboxylate superplasticizer produced by Tianjin Construction Engineering.

[0034] Among them, the density of ordinary Portland cement P.O 52.5R cement is 3.09g / cm3, the initial setting time is 1.5h, the final setting time is 5.0h, the 7d compressive strength is 38.1MPa, and the 28d compressive strength is 57.4MPa. The silicon dioxide content of micro-silica powder is 90%, the specific surface area is 23m2 / g, and the pH value is 7.1; the lightweight ceramsite adopts crushed stone ceramsite produced in Zigui, Hubei Province, with a particle size of 5-15mm and an apparent...

Embodiment 3

[0037] A kind of C50 high-strength and high-durability lightweight aggregate concrete and its preparation method

[0038] The main raw materials in each m3 volume of concrete are as follows: Ordinary Portland cement P.O 52.5340kg / m3 produced by Jidong Cement; micro-silica fume 190kg / m3; The mixing water specified in the industry standard JGJ 63-2006 "Water for Concrete" is 186kg / m3; the polycarboxylate superplasticizer produced by BASF in Germany is 6.36kg / m3.

[0039] Among them, the density of ordinary Portland cement P.O 52.5 cement is 3.05g / cm3, the initial setting time is 1.2h, the final setting time is 5.4h, the 7d compressive strength is 35.7MPa, and the 28d compressive strength is 56.2MPa. The inspection is qualified; the silicon dioxide content of micro silica fume is 92%, the specific surface area is 23m2 / g, and the pH value is 7.1; the lightweight ceramsite is crushed stone ceramsite produced in Zigui, Hubei, with a particle size of 5-15mm and an apparent density 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com