Metal resin composite material and preparing method thereof

A composite material, metal resin technology, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

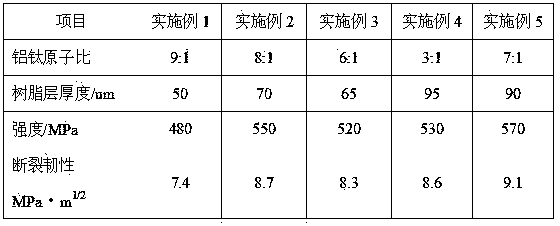

Embodiment 1

[0026] A metal resin composite material, comprising a metal matrix material and a surface coating,

[0027] Wherein the metal matrix material is Al-Ti alloy, wherein the atomic ratio of Al to Ti is 9:1;

[0028] The surface coating is a resin coating, which includes the following components in mass content: 30 parts of modified silicone resin; 3 parts of aluminum silicate fiber; 4 parts of nano-tin oxide; 3 parts of nano-zinc oxide; 4 parts of carbon fiber; 3 parts of coupling agent; 5-10 parts of dicumyl peroxide curing agent.

[0029] According to the preparation method provided by the present invention, the above-mentioned metal resin composite material is prepared, and the steps are as follows:

[0030] (1) Place Al powder and Ti powder in a casting furnace for high-temperature melting, then die-cast the alloy liquid at a pressure of 60 MPa, and cool after forming to prepare an Al-Ti alloy matrix material;

[0031] (2) Put the Al-Ti alloy matrix material into the mold, a...

Embodiment 2

[0036] A metal resin composite material, comprising a metal matrix material and a surface coating,

[0037] Wherein the metal matrix material is Al-Ti alloy, wherein the atomic ratio of Al to Ti is 8:1;

[0038] The surface coating is a resin coating, which includes the following components in mass content: 50 parts of modified silicone resin; 12 parts of aluminum silicate fiber; 9 parts of nano-tin oxide; 8 parts of nano-zinc oxide; 10 parts of carbon fiber; 9 parts of coupling agent; 10 parts of dicumyl peroxide curing agent.

[0039] According to the preparation method provided by the present invention, the above-mentioned metal resin composite material is prepared, and the steps are as follows:

[0040] (1) Place Al powder and Ti powder in a casting furnace for high-temperature melting, then die-cast the alloy liquid at a pressure of 60 MPa, and cool after forming to prepare an Al-Ti alloy matrix material;

[0041] (2) Put the Al-Ti alloy matrix material into the mold, a...

Embodiment 3

[0046] A metal resin composite material, comprising a metal matrix material and a surface coating,

[0047] Wherein the metal matrix material is an Al-Ti alloy, wherein the atomic ratio of Al to Ti is 6:1;

[0048] The surface coating is a resin coating, which includes the following components in mass content: 42 parts of modified silicone resin; 9 parts of aluminum silicate fiber; 5 parts of nano-tin oxide; 5 parts of nano-zinc oxide; 7 parts of glass fiber; 6 parts of silane coupling agent; 7 parts of vinyltriamine curing agent.

[0049] According to the preparation method provided by the present invention, the above-mentioned metal resin composite material is prepared, and the steps are as follows:

[0050] (1) Place Al powder and Ti powder in a casting furnace for high-temperature melting, then die-cast the alloy liquid at a pressure of 60 MPa, and cool after forming to prepare the Al-Ti alloy matrix material;

[0051] (2) Put the Al-Ti alloy matrix material into the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com