A kind of flue gas denitrification catalyst and its preparation method and application

A denitration catalyst and flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve the effect of widening the denitration temperature window, improving the resistance to SO2 poisoning, and improving the catalytic efficiency of denitration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of titanium crosslinking agent:

[0030] Under stirring conditions, tetrabutyl titanate was added dropwise into 6mol / L HCl aqueous solution, after stirring, 500 mL of deionized water was added, and stirring was continued to obtain a transparent crosslinking agent solution, which was aged at room temperature overnight. where Ti 4+ / H + 1 / 2, that is, every liter of HCl aqueous solution corresponds to 3 mol of tetrabutyl titanate.

[0031] Preparation of titanium layer pillar clay:

[0032] Add rectorite to deionized water to prepare a rectorite suspension with a mass fraction of 1%. Under stirring conditions, the prepared cross-linking agent solution was added dropwise to the rectorite suspension, stirred at room temperature for 3 hours, left standing overnight, washed and filtered until no Cl - (with AgNO 3 solution test), after pre-drying the obtained solid at room temperature, in a muffle furnace, the temperature was raised to 400°C at a rate of 3°C / mi...

Embodiment 2

[0039]The preparation method of Example 1 was used to prepare titanium-layered columnar rectorite, the difference being that the amount of crosslinking agent and the amount of CuO precursor and CaO precursor were changed to achieve a loading of CuO of 4wt%, CaTiO 3 The loading amount is 12wt%.

[0040] Catalytic Activity Detection

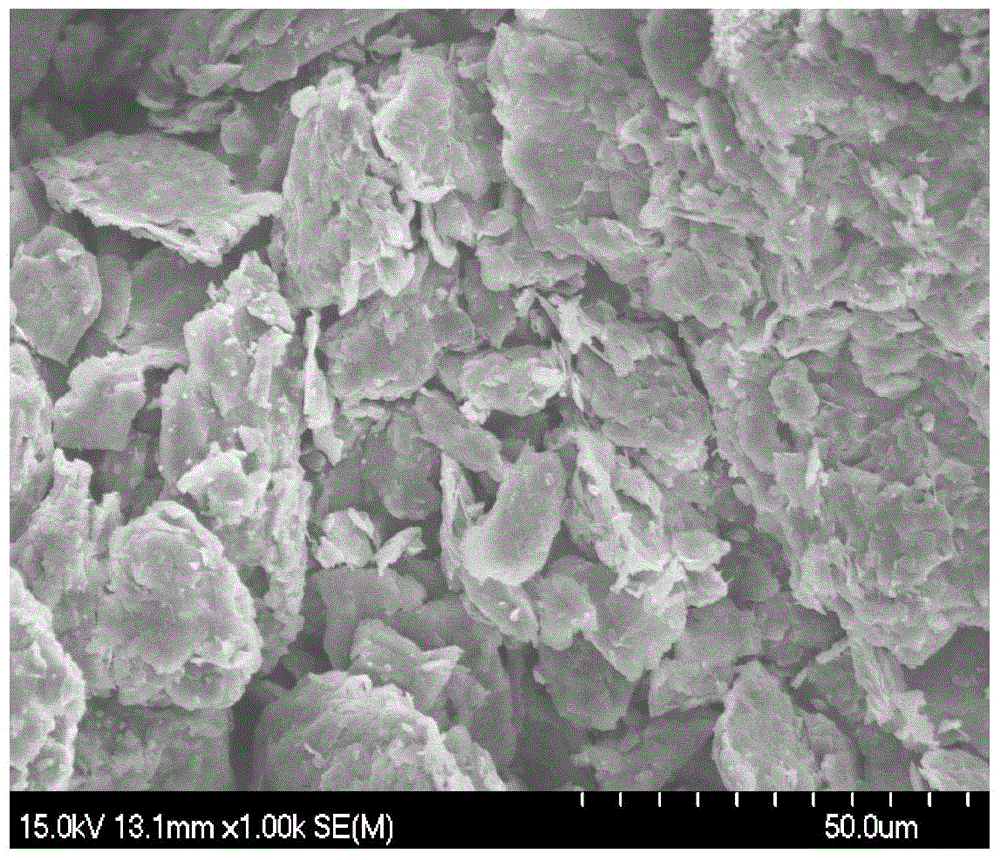

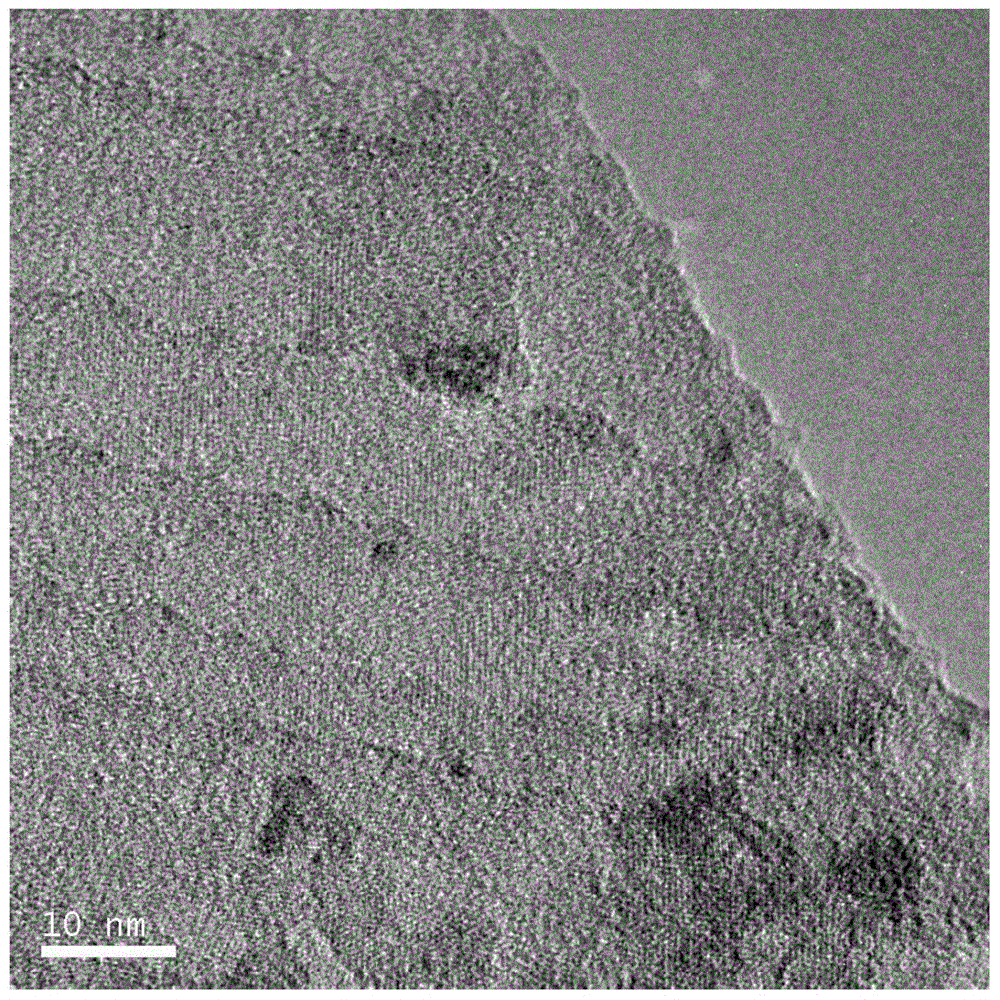

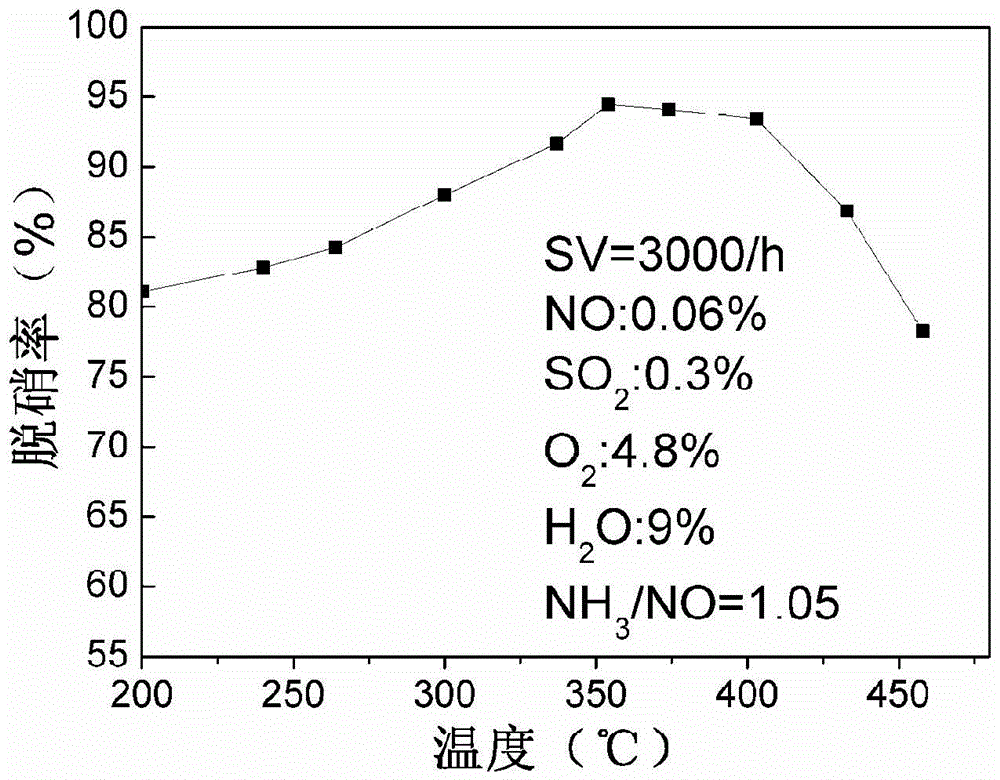

[0041] The catalytic material obtained in Example 2 is installed in a fixed-bed quartz reactor, and simulated flue gas is introduced, and its specific components are NO, NH 3 , O 2 , the activity of the catalyst was investigated under the condition of gas space velocity, and the electron micrograph of its microstructure is as follows figure 1 , 2 Shown; denitrification data results are shown in image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com