Gluten-free protein biscuit manufactured by sweet potato coarse dietary fibers and preparation method of gluten-free albumen cookie

A technology of dietary fiber and dietary fiber powder, applied in application, bakery, food science, etc., to achieve the effect of good crispiness, soft taste and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

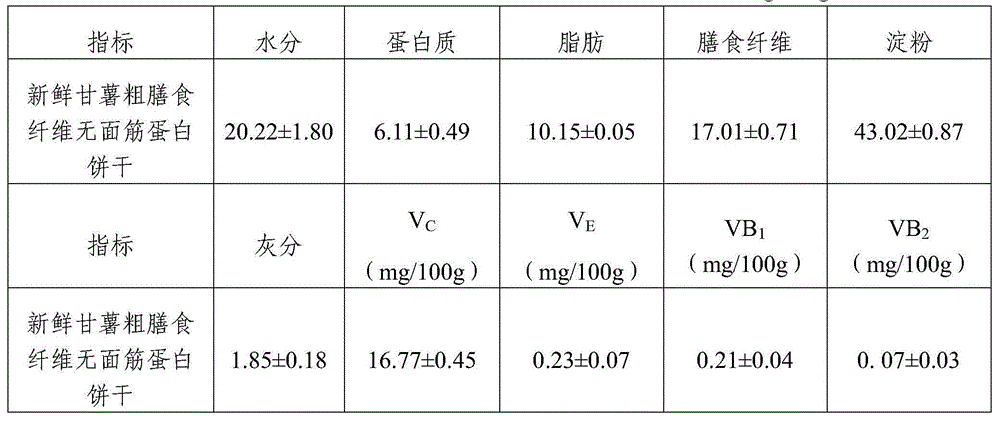

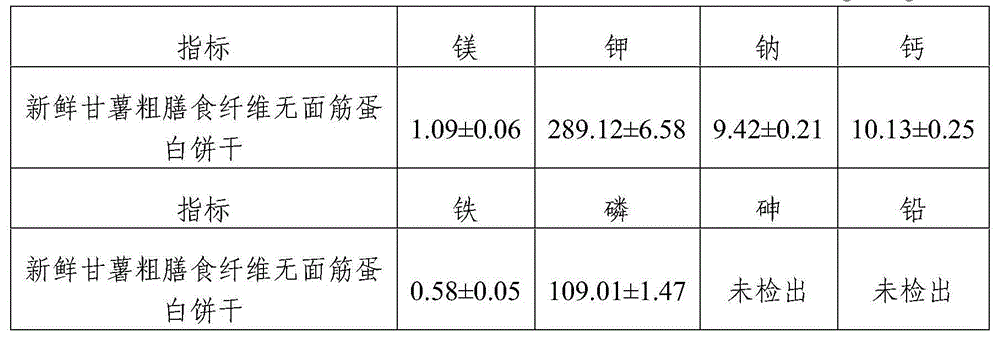

Examples

preparation example Construction

[0035] The preparation method of the sweet potato coarse dietary fiber superfine powder is as follows: adding wet sweet potato dietary fiber into a superfine pulverizer, pulverizing at room temperature for 1 minute, and passing through a 100-mesh sieve to obtain the product.

[0036] The preparation method of the sweet potato coarse dietary fiber nanometer powder is as follows: the raw sweet potato dietary fiber powder is mechanically milled to make the particle size less than 100nm.

[0037] The preparation method of the extruded puffed sweet potato coarse dietary fiber powder is as follows: adding the wet sweet potato dietary fiber into an extruder, extruding at 100°C, screw rotating speed at 800rpm, pulverizing with a universal grinder, and passing through a 100-mesh sieve to obtain the product.

[0038] The preparation method of the sweet potato crude dietary fiber microwave treatment powder is as follows: put the wet sweet potato dietary fiber in a microwave oven, the micr...

Embodiment 1

[0039] Example 1 Ratio of Raw Materials for Making Sweet Potato Coarse Dietary Fiber Gluten-Free Biscuits

[0040]In this embodiment, the raw materials used to make gluten-free protein biscuits from potato residues are: sweet potato coarse dietary fiber raw powder, sweet potato coarse dietary fiber superfine powder, sweet potato coarse dietary fiber nanopowder, sweet potato modified starch, and extruded sweet potato coarse meal Fiber powder, sweet potato coarse dietary fiber microwave processing powder, sweet potato starch, citrus pectin, sweet potato stem and leaf polyphenols, rice protein, trehalose, salt, baking soda, ammonium bicarbonate, edible oil and water, the weight ratio of the above raw materials The sequence is 25:21:12:8:10:10:5:1.5:0.5:2:10:0.5:0.5:0.3:20:60.

Embodiment 2

[0041] Example 2 Ratio of Raw Materials for Making Sweet Potato Coarse Dietary Fiber Gluten-free Biscuits

[0042] In this embodiment, the raw materials used to make gluten-free protein biscuits from potato residues are: sweet potato coarse dietary fiber raw powder, sweet potato coarse dietary fiber superfine powder, sweet potato coarse dietary fiber nanopowder, sweet potato modified starch, and extruded sweet potato coarse meal Fiber powder, sweet potato coarse dietary fiber microwave processing powder, sweet potato starch, sweet potato pectin, tea polyphenols, chickpea protein, trehalose, salt, baking soda, ammonium bicarbonate, edible oil and water, the weight ratio of the above raw materials The sequence is 25:30:10:8:6:11:2:1.5:0.6:2:10:2:0.6:0.2:25:55.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com