Method for preparing color carbon powder by adopting suspension polymerization method

A suspension polymerization method and color technology, applied in the fields of electrography, optics, instruments, etc., can solve the problems of unstable properties of inorganic colloidal stabilizers, high difficulty in co-flocculation process control, untreated coloring agents, etc. Stable, easy to operate, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

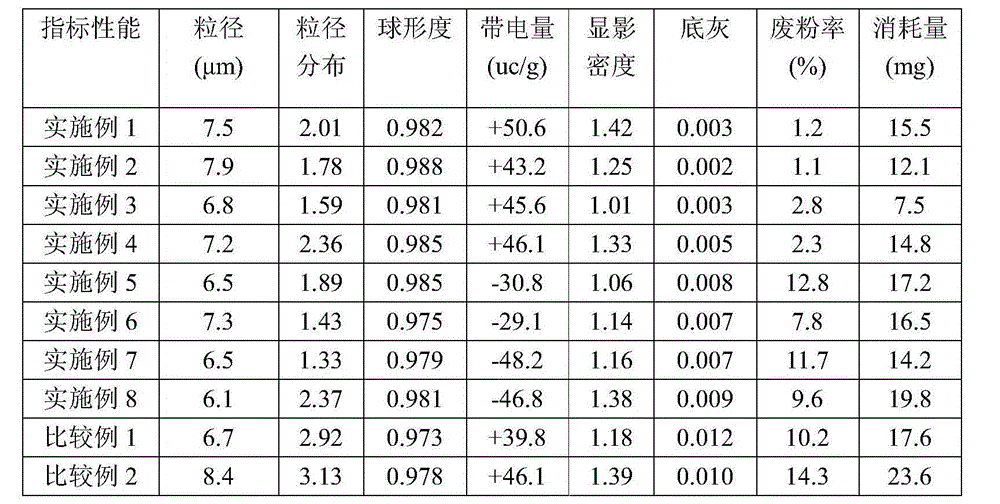

Examples

preparation example 1

[0038] Put 60 parts of toluene, 40 parts of isopropanol, 59 parts of styrene, 29 parts of butyl acrylate, 12 parts of aminostyrene, and 2 parts of initiator azobisisobutyronitrile into the reaction kettle, and stir evenly , heated to 75° C. for 10 hours, distilled off the solvent under reduced pressure, and cooled to obtain a light yellow transparent resin with a mass-average molecular weight Mw=40830 and a glass transition temperature Tg=72 degrees, which was called resin 1.

preparation example 2

[0040] Put 60 parts of toluene, 40 parts of isopropanol, 58 parts of styrene, 32 parts of butyl acrylate, 10 parts of sodium p-styrenesulfonate, and 2 parts of initiator azobisisoheptanonitrile into the reactor , stirred evenly, heated up to 67° C. and reacted for 10 hours, distilled off the solvent under reduced pressure, and cooled to obtain a light yellow transparent resin with a mass-average molecular weight Mw=48670 and a glass transition temperature Tg=65 degrees, which was called resin 2.

[0041] Preparation Example 1 of Color Masterbatch

[0042] Drop into 50 parts of carbon black (Monarch 700, Cabot, Cabot) and 50 parts of resin 1 in the melting kneading machine, obtain color masterbatch 1 through melt mixing, extruding, crushing, color masterbatch 1 is in toluene After dissolving, the particle diameter of the carbon black measured with a nanometer particle size analyzer is 116nm.

[0043] Preparation example 2 of color masterbatch

[0044] Drop into 43 parts of pi...

preparation example 3

[0046] Drop into 47 parts of pigment yellow 185 (Paliotol Gelb D 1155, BASF, BASF) and 53 parts of resin 1 in the melting kneader, obtain color masterbatch 3 through melt mixing, extruding, crushing, color masterbatch 3 is mixed in toluene After dissolving in medium, the particle size of Pigment Yellow 185 was measured with a nanometer particle size analyzer to be 376nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com