Artificially synthesized red coral and its preparation method

A kind of artificial synthesis and coral technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of complicated cultivation methods and long cycle of red coral, and achieve the effect of low price, bright color and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Mix 26g of calcium superoxide and 3g of graphite, then add 0.55g of iron oxide and 2.23g of magnesium oxide powder, put it into a ball mill jar, add 635.6g of stainless steel balls, mill for 30 minutes, press into tablets, and then use the six-sided top The press was kept at 2GPa and 500°C for 60mim to obtain 85CaCO 3 ·3Fe 2 o 3 ·12MgO artificially synthesized red coral block material. Such as figure 1 As shown, it can be seen that the prepared red coral appears pink.

Embodiment 2

[0019] Mix 26g of calcium superoxide and 3g of graphite, then add 2.23g of iron oxide and 0.55g of magnesium oxide powder, put it into a ball mill jar, add 794.5g of stainless steel balls, mill for 30 minutes, press into tablets, and then use the six-sided top The press was kept at 2GPa and 600°C for 60min to obtain 90CaCO 3 8Fe 2 o 3 ·2MgO artificially synthesized red coral block material. Such as figure 2 As shown, it can be seen that the prepared red coral presents a bright red color.

Embodiment 3

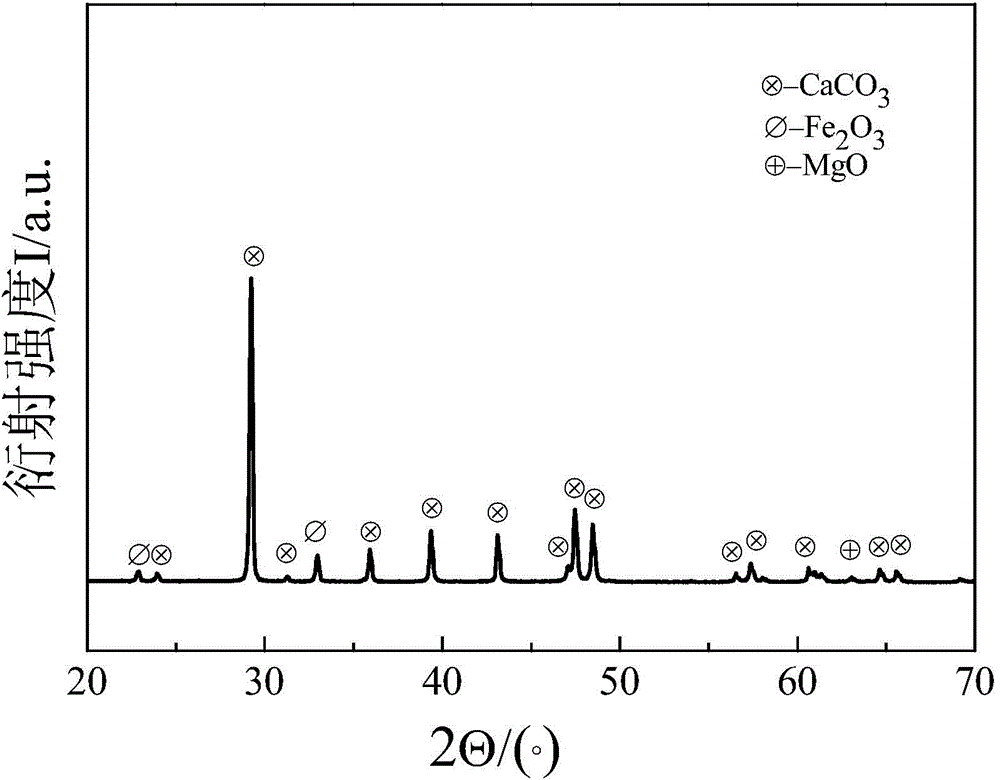

[0021] Mix 26g of calcium superoxide and 3g of graphite, then add 1.7g of iron oxide and 1.7g of magnesium oxide powder, put them into a ball mill jar, add 712.8g of stainless steel balls, mill for 30 minutes, press into tablets, and then use the six-sided top The press was kept at 2GPa and 550°C for 60min to obtain 88CaCO 3 6Fe 2 o 3 ·6MgO artificially synthesized red coral block material. Such as image 3 As shown, it can be seen that the prepared red coral materials mainly contain CaCO 3 , Fe 2 o 3 , MgO three mineral composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com