Catalyst for preparing 2-methyl furan through furfural gas phase hydrogenation and preparation method thereof

A technology of methyl furan and catalyst, applied in the field of catalyst preparation, can solve the problems of many by-products, environmental pollution, complex catalyst composition, etc., achieve high activity and selectivity, cheap and easy-to-obtain raw materials, and highlight the effect of low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

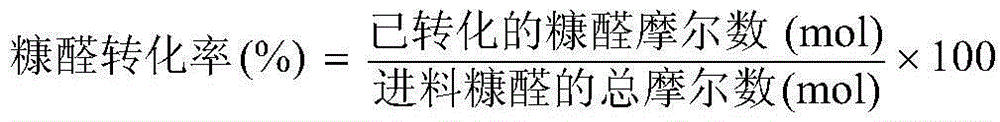

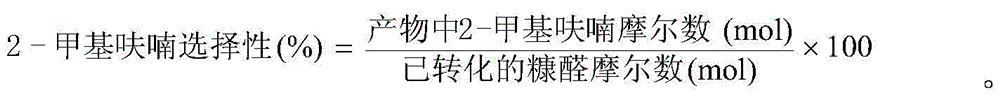

[0037] Embodiment 1, the preparation of catalyst and catalytic performance

[0038] 1. Preparation of catalyst

[0039] (1) Take copper nitrate 121g, silica sol 100g, cerium nitrate 10.7g, they are all dissolved in 500g deionized water, are made into mixed metal salt solution; Wherein, the molar concentration of copper nitrate is 1M, the molar concentration of cerium nitrate is 0.049M, and the molar concentration of silica sol is 1M.

[0040] (2) adding ammonia water with a mass fraction of 27% into the mixed solution prepared above, stirring to control the pH value to 12;

[0041] (3) Stir and heat in a water bath at 80°C to obtain a precipitate, wash and filter the precipitate, and dry at 100°C for 24 hours;

[0042] (4) The dried precipitate was calcined at 450° C. for 5 h, and finally pressed into tablets to obtain a catalyst sample.

[0043] The mass percent composition of the catalyst sample prepared in this embodiment consists of: CuO 53.8%, SiO 2 40.4% and CeO 2 5...

Embodiment 2

[0051] Embodiment 2, the preparation of catalyst and catalytic performance

[0052] 1. Preparation of catalyst

[0053] Weigh 122.5g of copper nitrate, 102.1g of sol, and 7.9g of cerium nitrate, and other conditions are the same as in Example 1.

[0054] The mass percentage composition of the catalyst sample prepared in this embodiment is: CuO 54.6%, SiO 2 41.1% and CeO 2 4.3%.

[0055] 2. Catalytic performance of the catalyst

[0056] Using the catalyst prepared above to catalyze the synthesis of 2-methylfuran from furfural, the specific steps and dosage are the same as those in Example 1.

[0057] Among them, the above reaction is carried out under the following conditions: the reaction temperature is 206°C, the pressure is 0.04MPa, the hydrogen aldehyde molar ratio is 20:1, and the furfural weight space velocity is 0.28h -1 Under the conditions, the conversion rate of furfural is about 100%, and the selectivity of 2-methylfuran reaches 92.6%.

Embodiment 3

[0058] Embodiment 3, the preparation of catalyst and catalytic performance

[0059] 1. Preparation of catalyst

[0060] Weigh 125.2 g of copper nitrate, 101.5 g of sol, and 6.1 g of cerium nitrate, and other conditions are the same as in Example 1.

[0061] The mass percent content of the catalyst sample prepared in this embodiment consists of: CuO 55.8%, SiO 2 41% and CeO 2 3.2%.

[0062] 2. Catalytic performance of the catalyst

[0063] Using the catalyst prepared above to catalyze the synthesis of 2-methylfuran from furfural, the specific steps and dosage are the same as those in Example 1.

[0064] Among them, the above reaction is carried out under the following conditions: the reaction temperature is 228°C, the pressure is 0.04MPa, the molar ratio of hydrogen aldehyde is 25:1, and the furfural weight space velocity is 0.29h -1 Under the conditions, the conversion rate of furfural is about 100%, and the selectivity of 2-methylfuran reaches 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com