Three-sectional expansion-resistance composite muffler applied at air outlet of heat pump

A technology at the muffler and tuyere, which is applied in the field of three-section expansion-resistive composite muffler, which can solve the problems of poor low-frequency processing effect, strong noise of heat pump units, and large footprint, so as to improve the sound insulation valley effect and good sound insulation Excellent performance and low wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

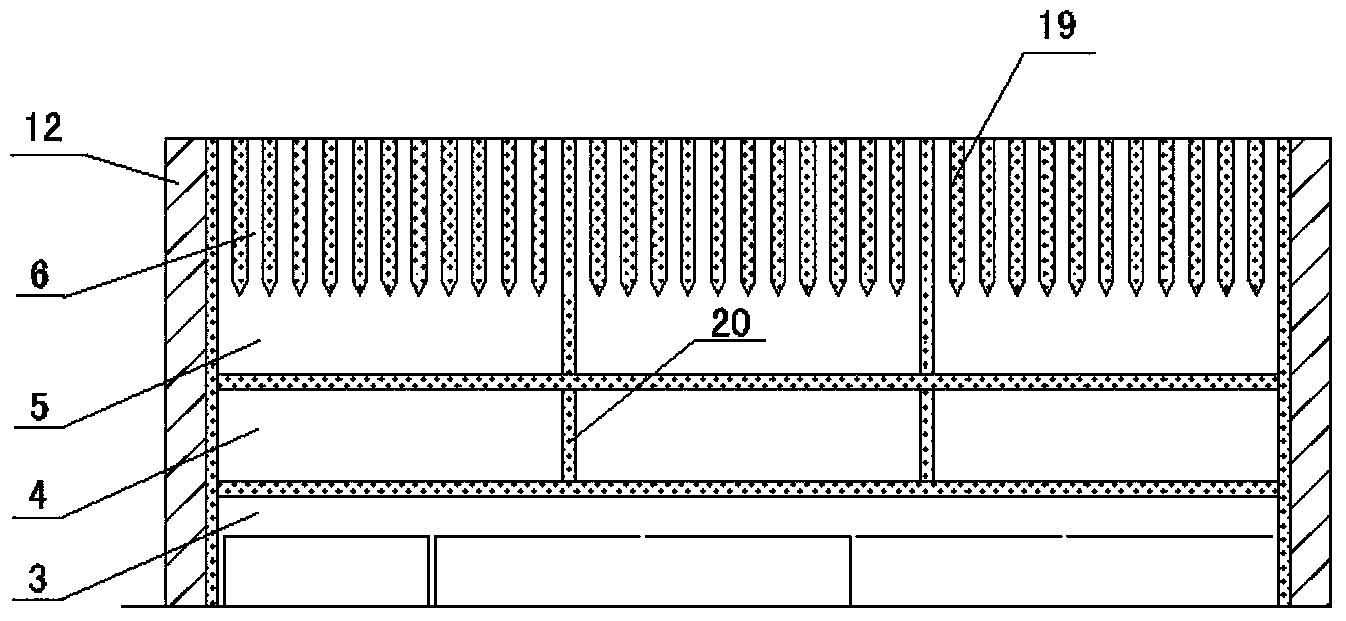

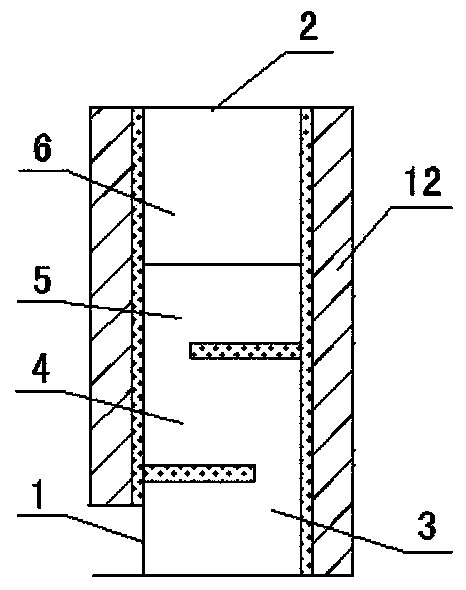

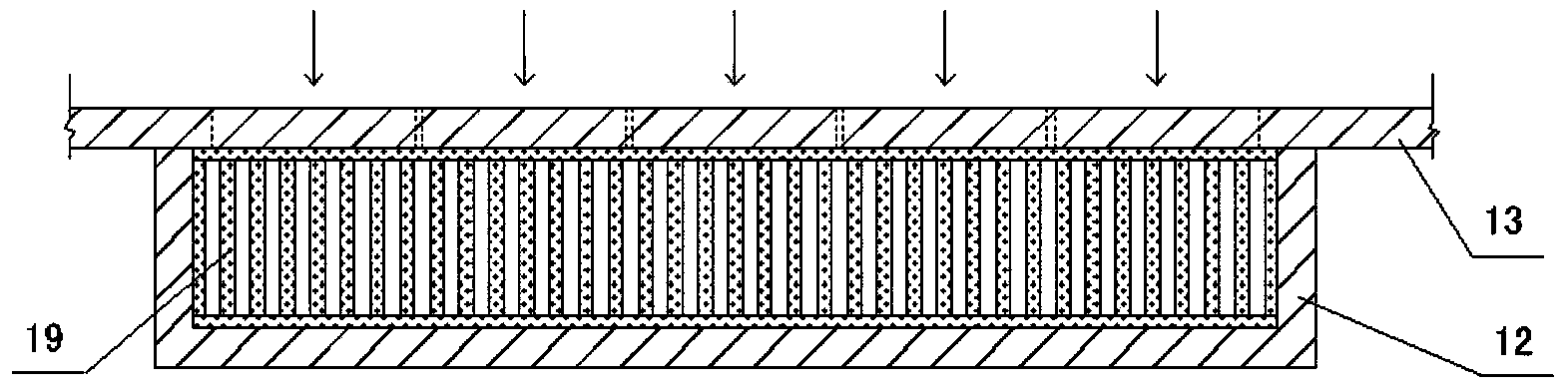

[0038] see figure 1 , figure 2 and image 3 In this embodiment, the structure of the three-section expansion-resistive composite muffler applied at the air outlet of the heat pump is set as follows: the air outlet 1 of the heat pump is connected by a pipe, and in the air duct from the air outlet 1 of the heat pump to the air outlet 2 of the muffler, The segments are arranged in series along the air outlet direction: the first expansion chamber 3, the second expansion chamber 4, the third expansion chamber 5 and the resistive muffler section 6, and the heat pump air outlet 1 is connected to the air inlet of the first expansion chamber 3 port, the muffler air outlet 2 is the air outlet port of the resistive muffler section 6; in the expansion chambers of each segment including the first expansion chamber 3, the second expansion chamber 4 and the third expansion chamber 5, this segment The air inlet and air outlet of the expansion chamber are in the staggered position; the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com