Space positioning control method of reverse arc wall template

A technology of spatial positioning and control method, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of inconvenient construction, bulky, uneconomical, etc. The construction process is simple and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

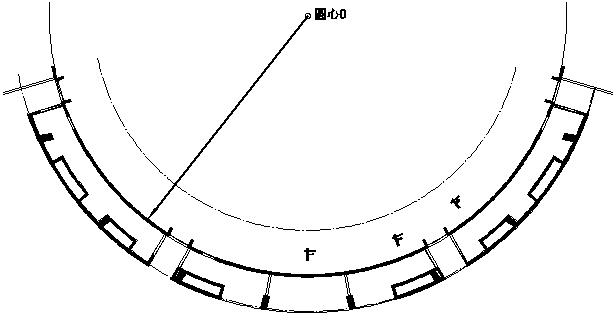

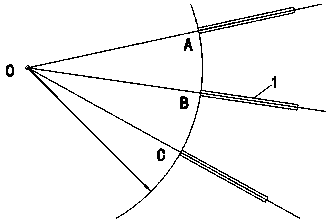

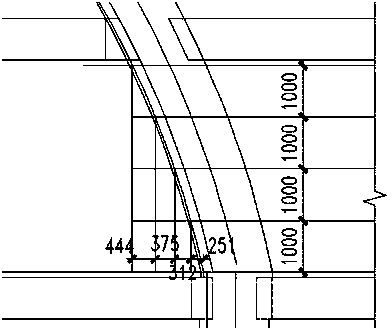

[0040] The present invention comprehensively considers the difficulty of shaping, cost, parts processing, construction and other factors, and decides to take the main flute as the three-dimensional shaping standard of the anti-arc wall, and then set the back flute and formwork on the basis of the main flute, and the main flute is made of steel pipe scaffolding. support to form a complete support system. The specific steps of this method are as follows,

[0041] 1) Determination of the main flute structure; the main flute is a welded arc-shaped H-shaped steel structure, the flange of the welded arc-shaped H-shaped steel is parallel to the anti-arc wall, and the welded arc-shaped H-shaped steel is bent in an arc shape along the length direction and vertical to the anti-arc wall Corresponding to the arc formed by the section; the flange of the welded arc-shaped H-shaped steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com