Thickener capable of improving hand feeling of pigment print and preparation method of thickener

A pigment printing and thickener technology, which is applied in dyeing, textiles and papermaking, can solve the problems of poor thickening ability and fastness, and achieve the effect of increasing color yield and improving hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The first step, the synthesis of soft oil:

[0026] Add 60 parts of castor oil into 10 parts of isopropanol, mix evenly, add 0.6 parts of p-toluenesulfonic acid, react at 175°C for four hours to obtain synthetic soft oil, and cool it for use.

[0027] The second step, the preparation of thickener:

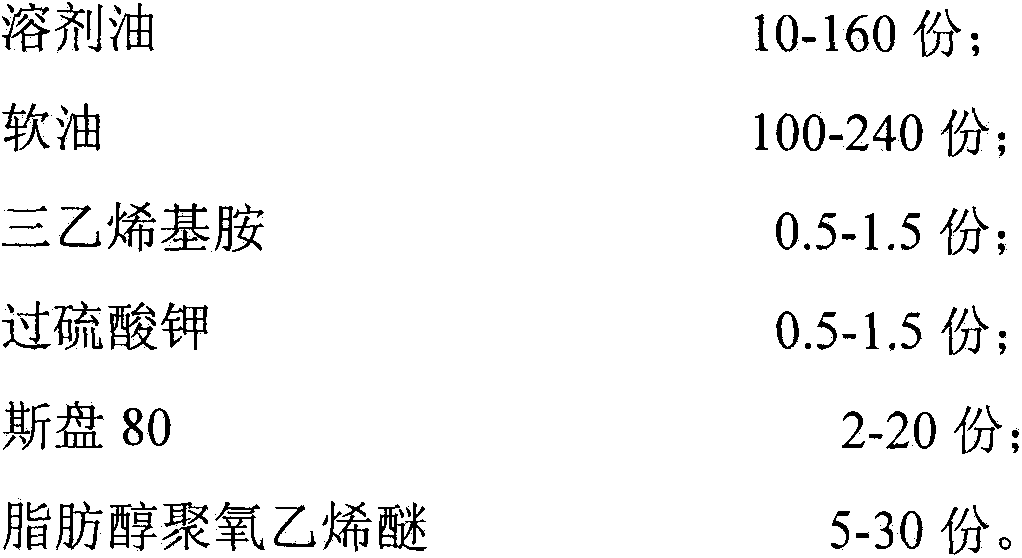

[0028] Adopt the following formula:

[0029] Acrylic acid, 150 parts; Acrylamide, 20 parts; Ammonia water, 200 parts; Deionized water, 200 parts; Solvent oil, 20 parts; Synthetic soft oil, 150 parts; Pan 80, 6 parts; Fatty alcohol polyoxyethylene ether, 6 parts.

[0030] Adopt following preparation method:

[0031] Add acrylamide dissolved in deionized water into the reaction bottle, then add acrylic acid, add ammonia water dropwise, and control the dropping rate so that the neutralization process temperature does not exceed 45°C; adjust the pH to 6.5; add synthetic soft oil, solvent oil, Mixture of trivinylamine, potassium persulfate and Span 80, emulsify for 30 minutes...

Embodiment 2

[0033] The first step, the synthesis of soft oil:

[0034] Add 60 parts of castor oil to 3 parts of isopropanol, mix evenly, add 0.8 parts of p-toluenesulfonic acid, react at 175°C for four hours to obtain synthetic soft oil, cool for later use.

[0035] The second step, the preparation of thickener:

[0036] Adopt the following formula:

[0037] Acrylic acid, 180 parts; Acrylamide, 30 parts; Ammonia water, 200 parts; Deionized water, 200 parts; Solvent oil, 20 parts; Synthetic soft oil, 120 parts; Pan 80, 8 parts; Fatty alcohol polyoxyethylene ether, 8 parts.

[0038] Adopt following preparation method:

[0039] Add acrylamide dissolved in deionized water into the reaction bottle, then add acrylic acid, add ammonia water dropwise, and control the dropping rate so that the temperature of the neutralization process does not exceed 45°C; adjust the pH to 5.5; add synthetic soft oil, solvent oil, Mixture of trivinylamine, potassium persulfate and Span 80, emulsify for 30 minu...

Embodiment 3

[0041] The first step, the synthesis of soft oil:

[0042] Add 30 parts of castor oil to 3 parts of isopropanol, mix evenly, add 0.1 part of p-toluenesulfonic acid, react at 175°C for four hours to obtain synthetic soft oil, cool for later use.

[0043] The second step, the preparation of thickener:

[0044] Adopt the following formula:

[0045] Acrylic acid, 150 parts; Acrylamide, 20 parts; Ammonia water, 190 parts; Deionized water, 100 parts; Solvent oil, 10 parts; Synthetic soft oil, 100 parts; Span 80, 2 parts; fatty alcohol polyoxyethylene ether, 5 parts.

[0046] Adopt following preparation method:

[0047] Add acrylamide dissolved in deionized water into the reaction bottle, then add acrylic acid, add ammonia water dropwise, and control the dropping rate so that the temperature of the neutralization process does not exceed 45°C; adjust the pH to 5.5; add synthetic soft oil, solvent oil, Mixture of trivinylamine, potassium persulfate and Span 80, emulsify for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com