Castable specially used for coal-injection ducts of 12000T cement kilns

A coal-injection pipe and castable technology, which is applied in the field of high-temperature materials for building materials, can solve problems such as uneven distribution of pores, segregation of castables, and poor workability, so as to improve corrosion resistance, prolong service life, and improve thermal shock resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

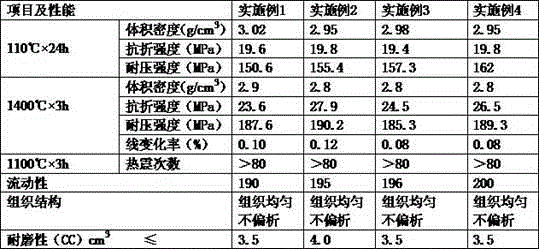

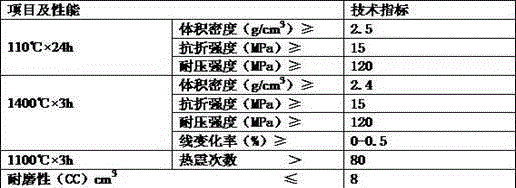

Examples

Embodiment 1

[0062] A 12000T cement kiln coal spray pipe special pouring material, the weight percentage of the component it contains is:

[0063] Gangyu spinelite 25%

[0064] 20% of synthetic carbon silica

[0065] Brown Gangyu 25%

[0066] 8% titanic acid powder

[0068] Red column stone powder 1%

[0070] 5% alumina microfan

[0071] Pure aluminum calcium acid 6%

[0072] Oxidation 2%

[0073] C 5 H 10 N 6 O 2 0.2%

[0074] 0.5% heat -resistant steel fiber

[0075] Sulfide 烯-Malayside Polymer 0.05%

[0076] Polyether polymer carboxylic acid 0.1%

Embodiment 2

[0078] A 12000T cement kiln coal spray pipe special pouring material, the weight percentage of the component it contains is:

[0079] Gangyu spinel 15%

[0080] 20% of synthetic carbon silica

[0081] Brown Gangyu 30%

[0082] 10% titanic acid powder

[0083] 8% carbonate powder

[0084] Red column stone powder 2%

[0086] 5% alumina microfan

[0087] Pure aluminum calcium acid 6%

[0088] Oxidation% 1%

[0089] C 5 H 10 N 6 O 2 0.2%

[0090] 0.5% heat -resistant steel fiber

[0091] Sulfide 烯-Malayside Polymer 0.05%

[0092] Polyether polymer carboxylic acid is 0.1%.

Embodiment 3

[0094] A 12000T cement kiln coal spray pipe special pouring material, the weight percentage of the component it contains is:

[0095] Gangyu spikes 20%

[0096] 15% synthetic carbon silica

[0097] Brown Gangyu 30%

[0098] 10% titanic acid powder

[0099] 8% carbonate powder

[0100] Red column stone powder 2%

[0102] 5% alumina microfan

[0103] Pure aluminum calcium acid 5%

[0104] Oxidation 2%

[0105] C 5 H 10 N 6 O 2 0.2%

[0106] 0.5% heat -resistant steel fiber

[0107] Sulfide 烯-Malayside Polymer 0.05%

[0108] Polyether polymer carboxylic acid 0.1%

[0109] TC 2 O 7 0.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com