C10+ heavy aromatic hydrocarbon hydrodealkylation catalyst and preparation method thereof

A technology for hydroalkyl and heavy aromatics, which is applied in the field of C10+ heavy aromatic hydroalkylation transalkylation catalyst and preparation field, can solve the problems of easy carbon deposition and deactivation of the catalyst, reduced BTX selectivity, large loss of alkyl group, etc. Renewable, high catalyst stability, high conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

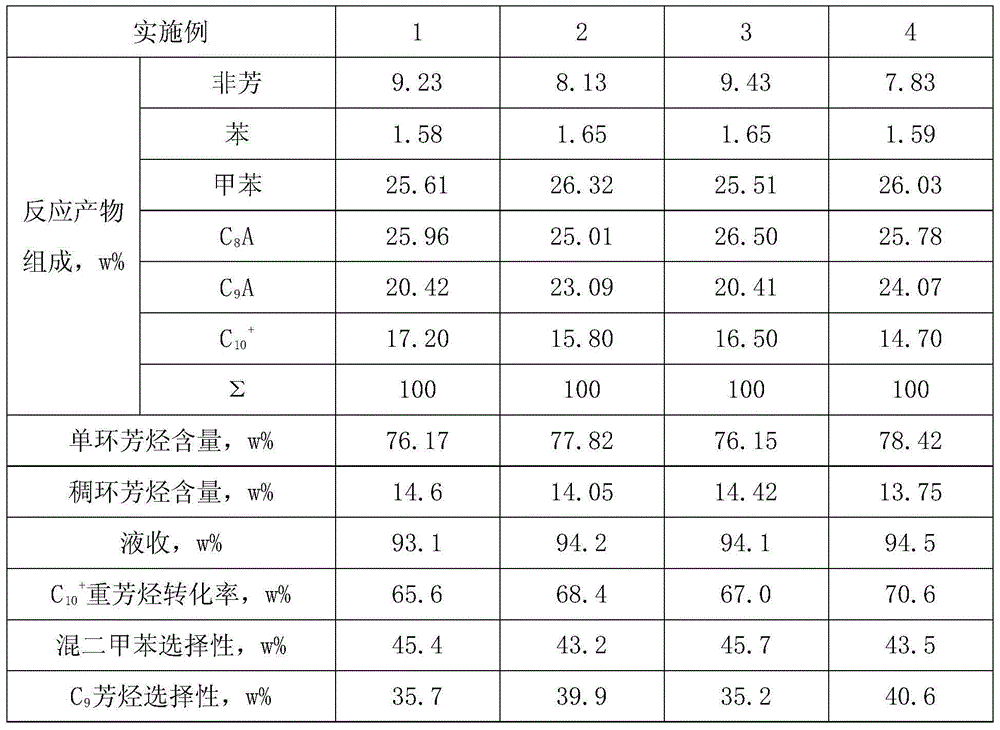

Embodiment 1

[0041] (1) Dissolve 80 grams of molecular sieves (dry basis, 56g HY and 24g HZSM-5) in 750ml deionized water, heat up to 80°C under stirring, add 5 grams of CeCl 3 ·7H 2 O, continue to stir for 2 hours, and filter and dry with 16gAl 2 o 3 (dry basis) mix evenly, add dilute nitric acid solution with a mass concentration of 3%, extrude the product into the form of a φ1.6 extrudate, dry at 110°C for 8 hours, and roast at 500°C for 4 hours in an air atmosphere to obtain a Ce-loaded Molecular sieve.

[0042] (2) 4 g of polyethylene glycol and 4 g of ammonium paramolybdate were dissolved in 155 ml of deionized water, while 1 mL of phosphoric acid was added dropwise, and stirred for 1 hour to obtain a highly dispersed solution.

[0043] (3) The molecular sieve obtained in step (1) was immersed in the solution obtained in step (2) for 12 hours, the product was dried at 110°C for 8 hours, and calcined at 500°C for 4 hours in an air atmosphere to obtain the finished catalyst 1.

Embodiment 2

[0045] (1) Dissolve 80 grams of molecular sieves (dry basis, 64g HY and 16g HZSM-5) in 750ml deionized water, heat up to 80°C under stirring, add 8.8 grams of Ce(NO 3 ) 3 ·6H 2 O, continue to stir for 2 hours, and filter and dry with 16gAl 2 o 3 (dry basis) mix evenly, add dilute nitric acid solution with a mass concentration of 3%, extrude the product into the form of a φ1.6 extrudate, dry at 110°C for 8 hours, and roast at 500°C for 4 hours in an air atmosphere to obtain a Ce-loaded Molecular sieve.

[0046] (2) Mix 4g of polyethylene glycol and 16g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 160ml of deionized water, and at the same time, 1mL of phosphoric acid was added dropwise, and stirred for 1 hour to obtain a highly dispersed solution.

[0047] (3) The molecular sieve obtained in step (1) was immersed in the solution obtained in step (2) for 12 hours, the product was dried at 110° C. for 8 hours, and calcined at 500° C. for 4 hours in an air atmosphere to obtain th...

Embodiment 3

[0049] (1) Dissolve 80 grams of molecular sieves (dry basis, 56g USY and 24g HZSM-5) in 750ml deionized water, heat up to 80°C under stirring, add 5 grams of CeCl 3 ·7H 2 O, continue to stir for 2 hours, and filter and dry with 16gAl 2 o 3 (dry basis) mix evenly, add dilute nitric acid solution with a mass concentration of 3%, extrude the product into the form of a φ1.6 extrudate, dry at 110°C for 8 hours, and roast at 500°C for 4 hours in an air atmosphere to obtain a Ce-loaded Molecular sieve.

[0050] (2) 4 g of polyethylene glycol, 4 g of ammonium paramolybdate and 4 g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 155ml of deionized water, and at the same time, 1mL of phosphoric acid was added dropwise, and stirred for 1 hour to obtain a highly dispersed solution.

[0051] (3) The molecular sieve obtained in step (1) was immersed in the solution obtained in step (2) for 12 hours, the product was dried at 110° C. for 8 hours, and calcined at 500° C. for 4 hours in an air at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com