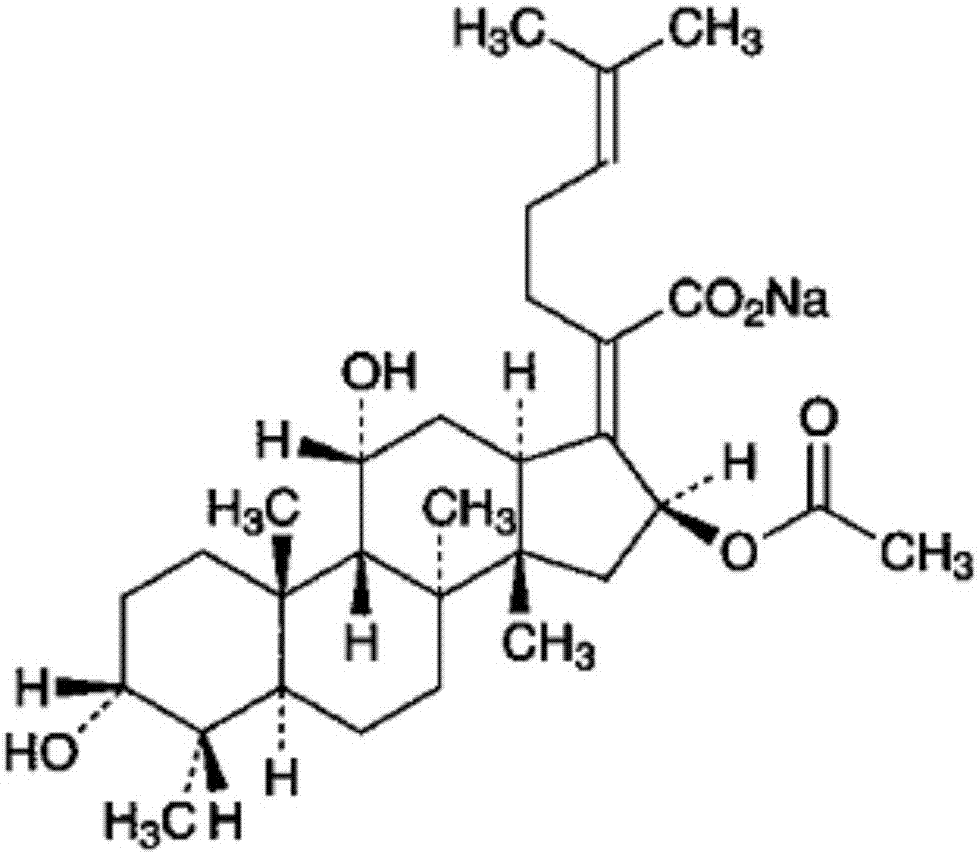

Pharmaceutical composition and preparation method of sodium fusidate powder for injection

A technology of sodium fusidate and its composition, which is applied in the field of medical technology and can solve problems such as turbidity, precipitation, and solvent reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] Embodiment 1: Preparation of sodium fusidate freeze-dried powder injection pharmaceutical composition

[0117] formula:

[0118] Sodium Fusidate 0.5g,

[0119] Glycine 0.2g,

[0120] Arginine 0.2g,

[0121] Add water for injection, appropriate amount, to 8ml.

[0122] Preparation method:

[0123] (a) Take the active ingredient of prescription quantity and neutral amino acid and basic amino acid, add appropriate amount of water for injection to dissolve, then add activated carbon, stir, filter and decarbonize;

[0124] (b) Add water for injection to the prescribed amount, stir evenly, measure the pH value of the solution and optionally measure the active ingredient content, and adjust the pH value to 8.0 to 8.5 with an acid-base regulator if necessary;

[0125] (c) Sterilize and filter the medicinal liquid, fill it in a vial, freeze-dry to remove water, and press the stopper to obtain the product.

[0126] Wherein the water for injection mentioned in the prescrip...

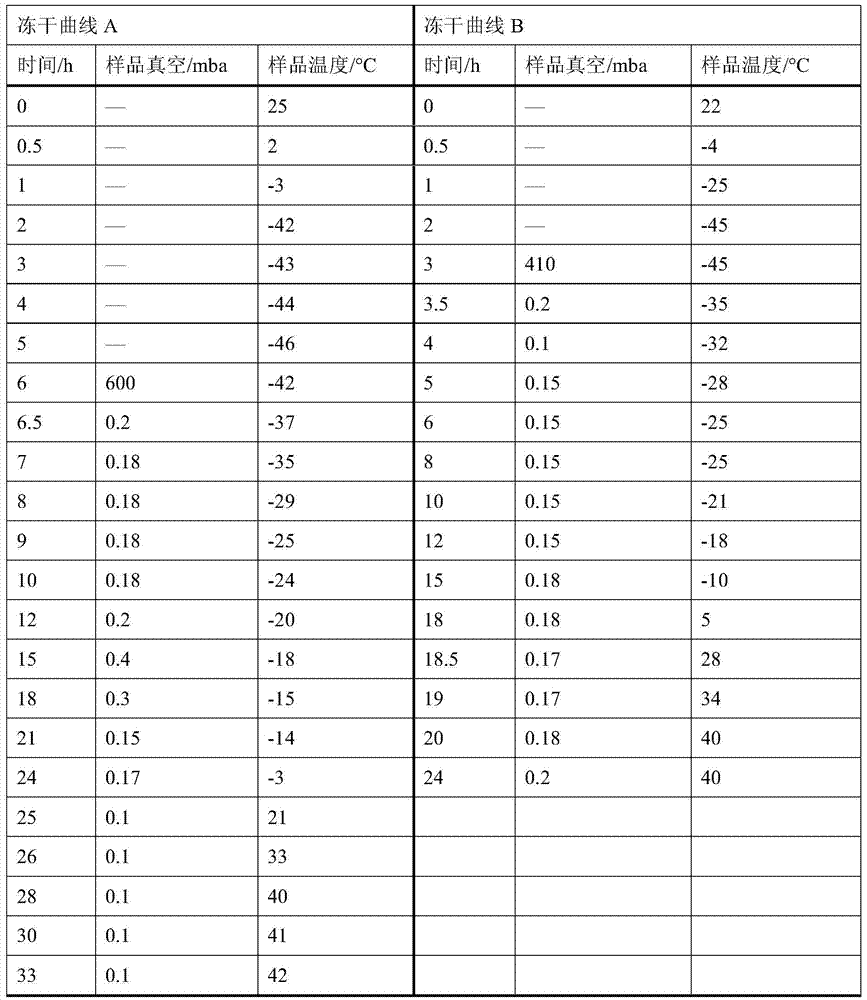

Embodiment 2

[0127] Embodiment 2: Preparation of sodium fusidate freeze-dried powder injection pharmaceutical composition

[0128] formula:

[0129] Sodium Fusidate 0.5g,

[0130] Glycine 0.08g,

[0131] Arginine 0.165g,

[0132] Add water for injection, appropriate amount, to 4ml.

[0133] Preparation method:

[0134] (a) Take the active ingredient of prescription quantity and neutral amino acid and basic amino acid, add appropriate amount of water for injection to dissolve, then add activated carbon, stir, filter and decarbonize;

[0135] (b) Add water for injection to the prescribed amount, stir evenly, measure the pH value of the solution and optionally measure the content of active ingredients, and adjust the pH value to 8.0 to 8.5 with an acid-base regulator if necessary;

[0136](c) Sterilize and filter the medicinal liquid, fill it in vials, freeze-dry (freeze-drying curve B) to remove water, and press stopper to obtain the product.

Embodiment 3

[0137] Embodiment 3: Preparation of sodium fusidate freeze-dried powder injection pharmaceutical composition

[0138] formula:

[0139] Sodium Fusidate 0.5g,

[0140] Glycine 0.2g,

[0141] Arginine 0.2g,

[0142] Mannitol 0.25g,

[0143] Add water for injection, appropriate amount, to 10ml.

[0144] Preparation method:

[0145] (a) Take the active ingredient and mannitol, neutral amino acid and basic amino acid of the prescribed amount, add appropriate amount of water for injection to dissolve, then add activated carbon, stir, filter and decarbonize;

[0146] (b) Add water for injection to the prescribed amount, stir evenly, measure the pH value of the solution and optionally measure the active ingredient content, and adjust the pH value to 8.0 to 8.5 with an acid-base regulator if necessary;

[0147] (c) Sterilize and filter the medicinal liquid, fill it in a vial, freeze-dry to remove water, and press the stopper to obtain the product.

[0148] Wherein the water fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com