Chemically strengthened glass plate, cover glass, chemically strengthened glass with touch sensor, and display device

A touch sensor, tempered glass technology, used in the identification of devices, instruments, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

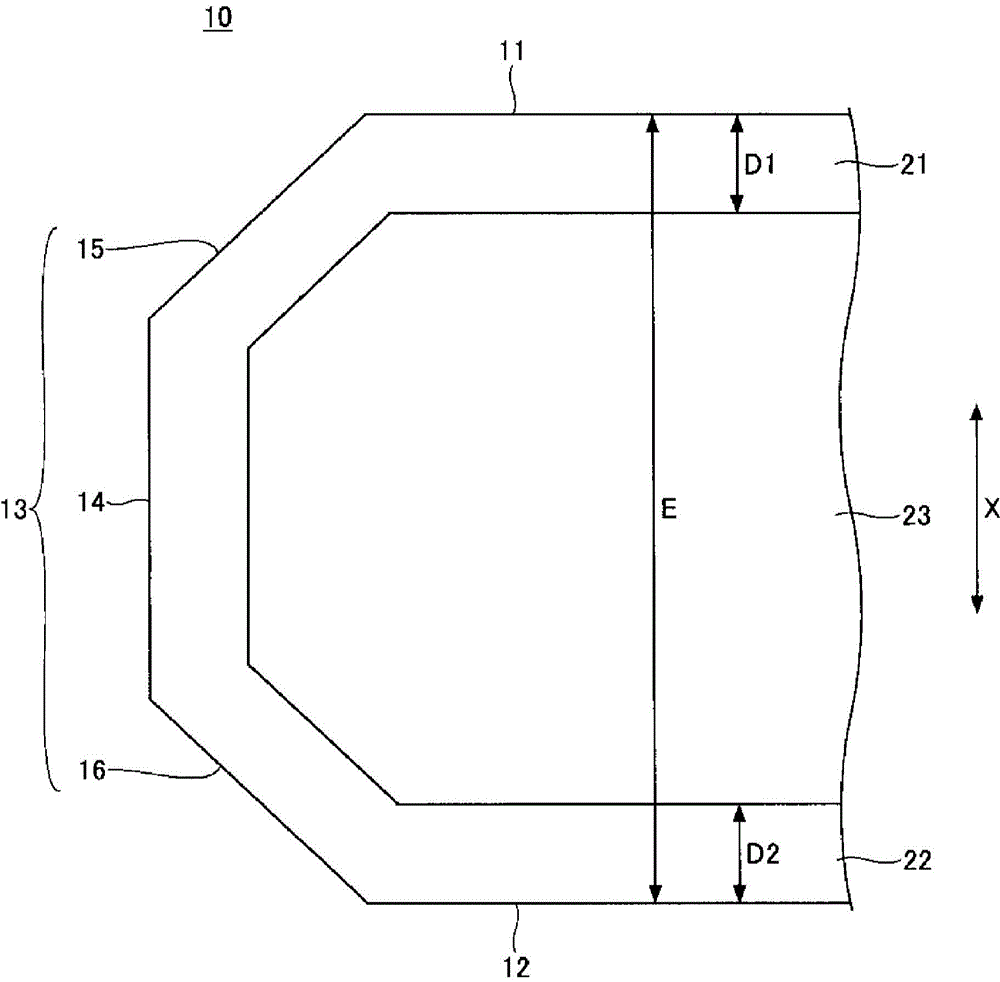

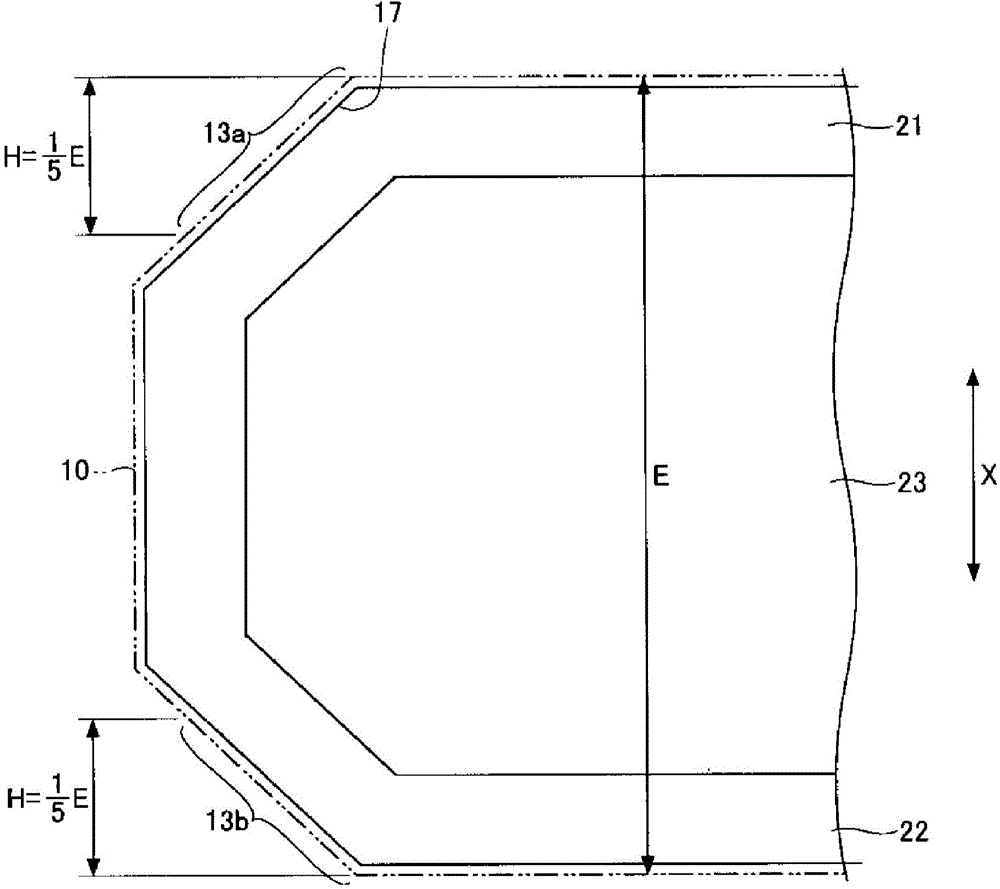

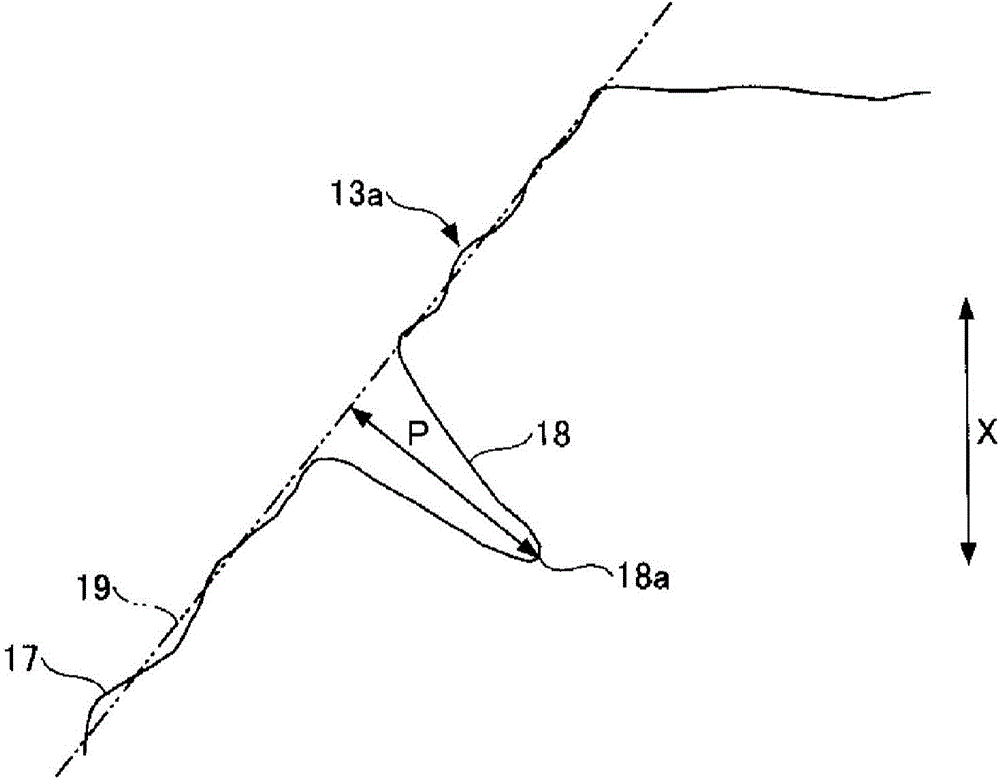

[0182] Figure 1 ~ Figure 3 It is explanatory drawing of the manufacturing method of the glass plate which concerns on 1st Embodiment of this invention.

[0183] The glass pane 10 has a front main face 11 and a rear main face 12 as well as an end face 13 adjoining the two main faces 11 , 12 . The two main surfaces 11, 12 are flat surfaces parallel to each other.

[0184] The end face 13 is composed of a flat portion 14 perpendicular to the two main faces 11 , 12 and chamfered portions 15 , 16 formed between the respective main faces 11 , 12 and the flat portion 14 . The flat portion 14 may be an original cut surface obtained by cutting a sheet glass having an area larger than that of the glass plate 10 , or may be a processed surface obtained by processing a cut surface.

[0185] For example, four chamfered parts 15 and 16 may be provided corresponding to the four sides of the rectangular main surfaces 11 and 12, or only one may be provided, and the number of chamfered parts...

no. 2 approach

[0202] This embodiment relates to the manufacturing method of the glass plate which has a chamfered part.

[0203] Figure 4 ~ Figure 6 It is explanatory drawing of the manufacturing method of the glass plate of 2nd Embodiment of this invention. Figure 4 A laminate 130 including a glass plate 110 as an original plate and a brush 140 for polishing the outer edge of the laminate 130 are shown. Figure 5 The state in which the outer edge portion of the laminated body 130 is polished by the brush 140 is shown enlarged. Figure 6 In , the glass plate 110A after brush grinding is indicated by a solid line, and the glass plate 110 before brush grinding is indicated by a two-dot chain line.

[0204] The method of manufacturing a glass plate includes a lamination step of producing a laminated body 130 by interposing spacers 120 between glass plates 110 , and a polishing step of polishing the outer edge of the laminated body 130 with a brush 140 . In addition, the manufacturing meth...

no. 3 approach

[0222] This embodiment relates to the manufacturing method of the glass plate which has a chamfered part. In this embodiment, before producing a laminated body, the process of grinding the outer edge part of a glass plate is further included.

[0223] Figure 7 ~ Figure 9 It is explanatory drawing of the manufacturing method of the glass plate of 3rd Embodiment of this invention. Figure 7 A glass plate 110 as an original plate and a rotating grindstone 240 for grinding the outer edge of the glass plate 110 are shown. Figure 8 The magnification shows the use of the brush 140 (reference Figure 4 ) A state in which the outer edge portion of the laminated body 130B including the glass plate 110B ground by the rotary grindstone 240 is ground. Figure 9 In , the glass plate 110C after brush grinding is indicated by a solid line, and the glass plate 110B before brush grinding is indicated by a dashed-two dotted line.

[0224] The method of manufacturing a glass plate includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com