Coercive-force-enhanced NdFeB thermal deformation magnet as well as preparation method and application thereof

A technology of NdFeB and coercive force, which is applied in the fields of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., and can solve the problems of limited performance improvement of NdFeB magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

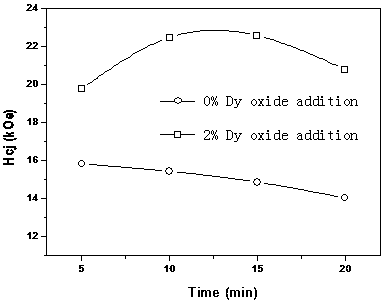

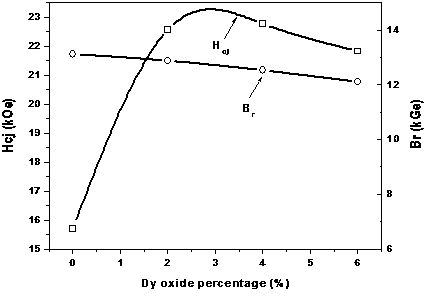

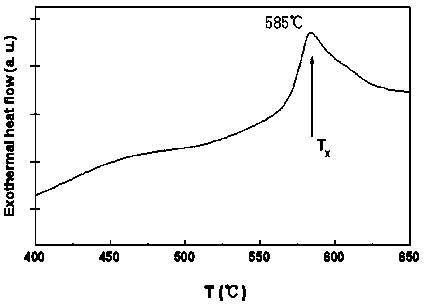

Method used

Image

Examples

Embodiment 1

[0060] In this embodiment, the NdFeB system thermally deformable magnet with enhanced coercive force, the crystallized thin ribbon mixture (that is, the Nd-Fe-B system nanocrystalline magnetic powder) is mainly composed of (by weight fraction), neodymium: 30%, Praseodymium: 0%, Dysprosium: 0%, Terbium: 0%, Gallium: 0.5%, Copper: 0%, Cobalt: 6%, Boron: 5.6%, the balance is Fe and other unavoidable impurities, heavy rare earth oxides Preferably, dysprosium oxide accounts for 0.2% of the total mass of the crystallized ribbon-shaped mixture. The metal material composed of the crystallized thin ribbon-shaped mixture is formed into a thin ribbon-shaped sheet through a melting and rolling process, and then the crystallized thin ribbon-shaped mixture material is obtained by mechanical crushing. The particle size of dysprosium oxide is 0.2 μm. The thickness of the nanocrystalline fast-quenching band is 20 μm, and the grain size is about 15 nm.

[0061] Dysprosium oxide and the ab...

Embodiment 2

[0066] In this embodiment, the NdFeB hot deformable magnet with enhanced coercive force, the main composition of the crystallized thin ribbon mixture is (in terms of weight fraction), neodymium: 31%, praseodymium: 0%, dysprosium: 0%, terbium: 0%, Gallium: 0.2%, Copper: 0%, Cobalt: 0%, Boron: 6%, the balance is Fe and other unavoidable impurities, and the heavy rare earth oxide is preferably dysprosium oxide to account for the total mass of the crystallized thin ribbon mixture 0.1% of. The metal material composed of the crystallized thin ribbon-shaped mixture is formed into a thin ribbon-shaped sheet through a melting and rolling process, and then the crystallized thin ribbon-shaped mixture material is obtained by mechanical crushing. The particle size of dysprosium oxide is 0.1 μm. The thickness of the nanocrystalline fast-quenching band is 10 μm, and the grain size is about 17 nm.

[0067] Dysprosium oxide and the above-mentioned Nd-Fe-B nanocrystalline magnetic powder ...

Embodiment 3

[0072] In this embodiment, the NdFeB system heat deformable magnet with enhanced coercive force, the main composition of the crystallized thin ribbon mixture is (in terms of weight fraction), neodymium: 29%, praseodymium: 0%, dysprosium: 0%, terbium: 0%, gallium: 0.3%, copper: 0.1%, cobalt: 6%, boron: 5.5%, the balance is Fe and other unavoidable impurities, and the heavy rare earth oxide is preferably dysprosium oxide in the total mass of the crystallized thin ribbon mixture 1%. The metal material composed of the crystallized thin ribbon-shaped mixture is formed into a thin ribbon-shaped sheet through a melting and rolling process, and then the crystallized thin ribbon-shaped mixture material is obtained by mechanical crushing. The particle size of dysprosium oxide is 1 μm. The thickness of the nanocrystalline fast-quenching band is 30 μm, and the grain size is about 17 nm.

[0073] Dysprosium oxide and the above-mentioned Nd-Fe-B nanocrystalline magnetic powder are uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com