A novel etching process for coating and etching a metal workpiece

A technology for metal workpieces and new processes, applied in metal processing equipment, coatings, electrolytic coatings, etc., can solve problems such as many processes, environmental protection impact, complexity, etc., to reduce chemical residues, reasonable process settings, and high product accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

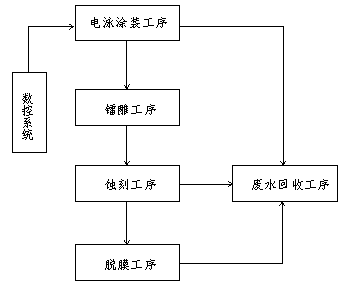

[0015] See attached figure 1 , the present invention includes an electrophoretic coating process for coating electronic parts, a radium engraving process for engraving electronic parts, an etching process for graphic processing of electronic parts coatings, and an etching process for electronic parts. The stripping process for detaching the coating of the parts also includes a waste water recovery process, and the waste water recovery process is used to recycle the waste water generated in the electrophoretic coating process, etching process, and film stripping process.

[0016] The electrophoretic coating process is connected to the numerical control system and is automatically controlled by the numerical control system. The combination of numerical control technology and electrophoretic coating process realizes the fully automatic production of electrophoretic coating process.

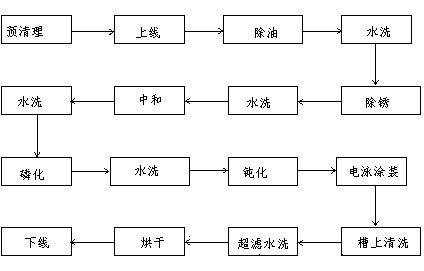

[0017] See attached figure 2 , the technical process of the electrophoretic coating process des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com