Lithium-rich technology for lithium-ion batteries and lithium-ion batteries prepared using the technology

A lithium-ion battery, lithium-rich technology, used in battery electrodes, electrolyte battery manufacturing, electrode manufacturing and other directions, can solve battery safety hazards, lithium powder floating, increase battery thickness and other problems, improve battery safety performance, avoid oxidation and Floating to the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

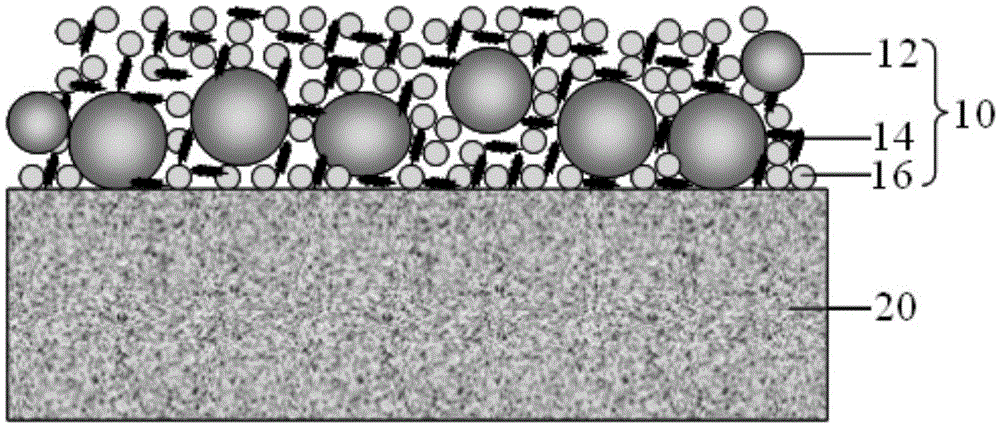

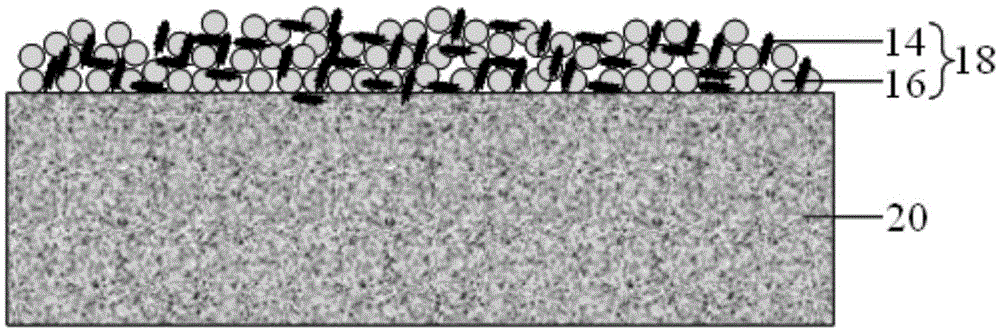

Embodiment 1

[0041] Lithium powder (with Li 2 CO 3 Coating layer, particle size D50 is 3 μm) and EC powder (particle size D50 is 30 μm) are added to the mixing tank according to the mass ratio of 20:20, and then the powder is mixed with a plastic stirring blade at a speed of 30 rpm. The solid mixture was stirred for 30 min. The powder mixture is sampled multiple times using a statistical method, and then inspected by visual inspection (based on different powders having different colors) and high-power optical microscopy (based on different powders having different shapes) to ensure that the mixed powder is evenly dispersed Finally, heat the uniformly mixed powder to 45°C to melt the EC powder into an EC solution: since the mixture of the above powders has been mixed uniformly in a dry-mixed state, the lithium powder has been in a uniformly dispersed form after EC solvation Exist in EC solvent. Through particle size measurement and monitoring, it was confirmed that the particle size of t...

Embodiment 2

[0053] Lithium powder (with Li 2 CO 3 Coating layer, particle size D50 is 10μm), SiO 2 Ceramic powder (particle size D50 is 0.2 μm), PAANa powder, EC powder (particle size D50 is 100 μm) are added in the mixing tank according to the mass ratio of 9:4:4:22, and then the plastic stirring paddle is used for 30 Stir the powder mixture for 45 minutes at a speed of rev / min. The powder mixture is sampled multiple times using a statistical method, and then inspected by visual inspection (based on different powders having different colors) and high-power optical microscopy (based on different powders having different shapes) to ensure that the mixed powder is evenly dispersed Finally, heat the uniformly mixed powder to 45°C to melt the EC powder into an EC solution, and at the same time, dissolve the PAANa powder into the EC solution to form an EC solvent with a certain viscosity: since the mixture of the above powders has been mixed in a dry mixing state Uniform, so lithium powder ...

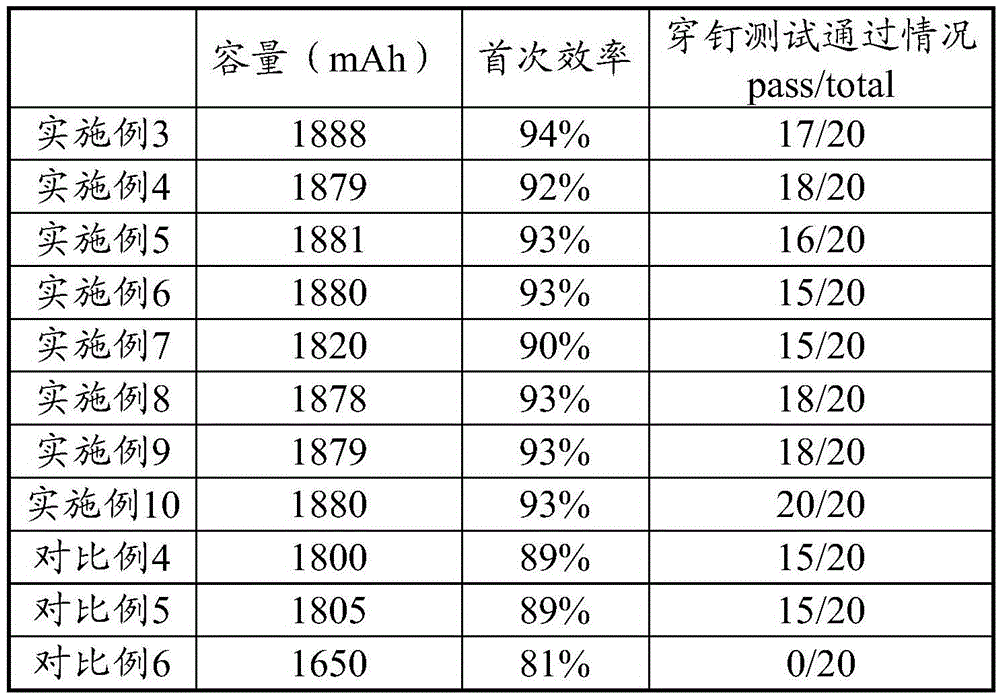

Embodiment 3

[0058] First at room temperature, that is, at 25°C, lithium powder (same as Example 2), Al 2 o 3Ceramic powder (particle size D50 is 0.5 μm), PVDF powder, SuperP conductive powder, EC powder (particle size D50 is 60 μm) are added into the mixing tank according to the mass ratio of 9:7:3:1:20, and then Stir the powder mixture for 30 min with a plastic stirring paddle at a speed of 30 rpm. The powder mixture is sampled multiple times using a statistical method, and then inspected by visual inspection (based on different powders having different colors) and high-power optical microscopy (based on different powders having different shapes) to ensure that the mixed powder is evenly dispersed Finally, heat the uniformly mixed powder to 45°C to melt the EC powder into an EC solution, and at the same time, dissolve the PVDF powder into the EC solution to form an EC solvent with a certain viscosity: since the mixture of the above powders has been mixed in a dry mixing state Uniform, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com