800mpa grade cold-rolled dual-phase steel and production method thereof

A production method and 800mpa technology, applied in the field of metallurgical sheet production, can solve the problems of unfavorable continuous production, reduced smelting castability, and insignificant effect, and achieve the effects of low cost, good production continuity and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

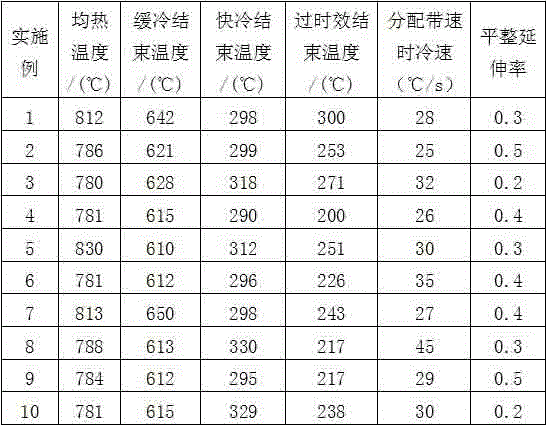

[0013] Embodiments 1 to 10: The 800MPa grade cold-rolled dual-phase steel is produced by converter smelting, LF refining, RH refining, continuous casting, hot rolling and cold rolling and continuous annealing processes; the final chemical composition and process conditions of the production method are as follows stated.

[0014] (1) Converter smelting, LF refining, RH refining and continuous casting process:

[0015] Requirements for molten iron in the converter smelting process: S ≤ 0.040wt%, desulfurization target S ≤ 0.010wt%, scrap steel added accounts for 4-8wt% of the total mass of molten iron, and the ratio of molten iron ≥ 85wt%.

[0016] In the LF refining process, the alkalinity is controlled at 4.0-4.5, and the end target C≤0.055wt%, P<0.007wt%, S≤0.02wt%.

[0017] LF Ladle Bottom Blowing Ar is opened to a flow rate of 80Nm 3 / h, the processing time is controlled within 40 minutes, under the premise of burying the arc, the positive pressure is guaranteed throughou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com