Method for efficient separation and recycling of precious metals in waste circuit board

A technology for waste circuit boards and precious metals, applied in the field of efficient separation and recovery of precious metals in waste circuit boards, can solve the problems of low cost and no pollution, achieve significant economic benefits and alleviate the shortage of metal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

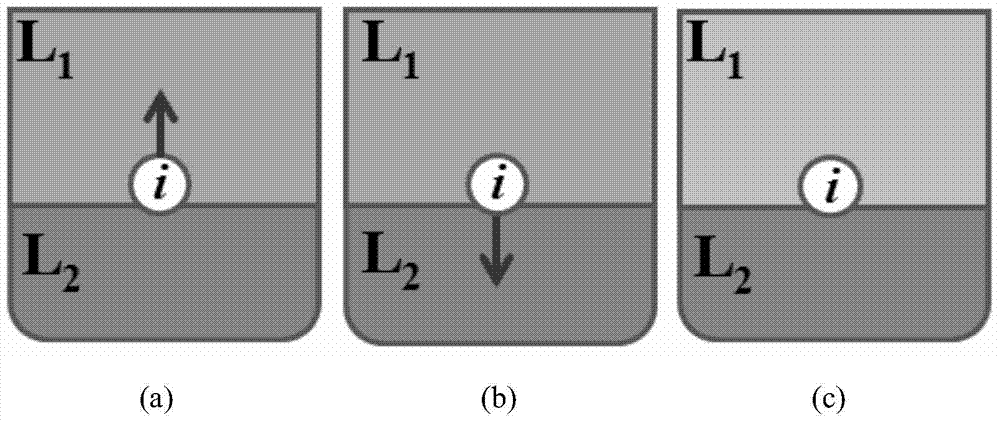

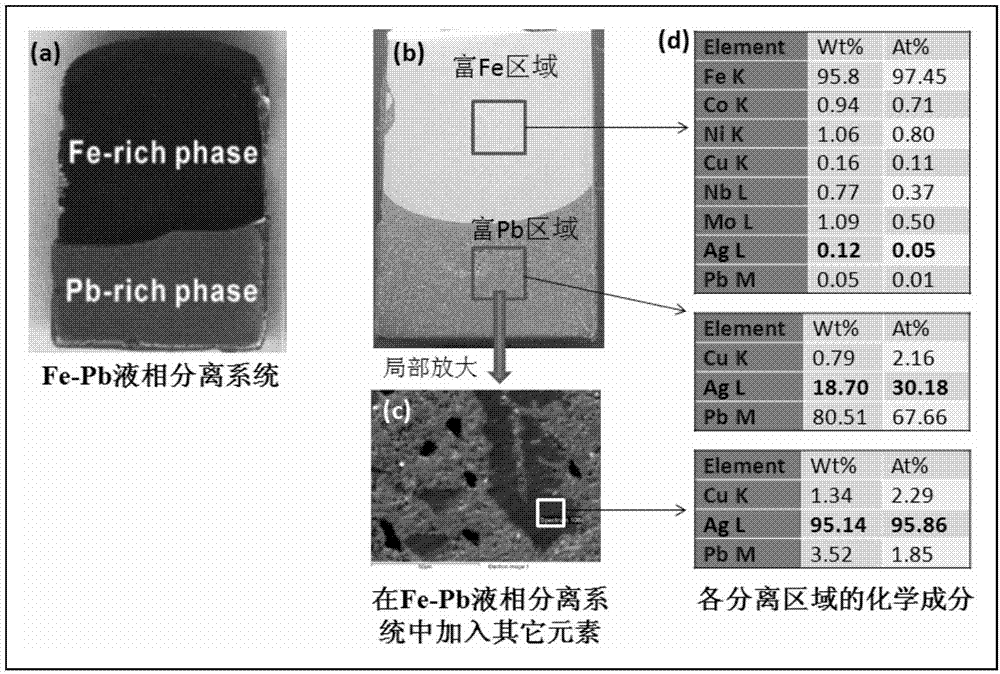

[0045] In this embodiment, the method for efficiently separating and recovering precious metals from waste circuit boards utilizes the selective distribution of metal elements in waste circuit boards in a liquid phase separation system to achieve efficient separation of multi-metal components. Carry out a confirmatory experiment on it. Based on the composition of metal materials in waste circuit boards, a Fe-Pb liquid phase separation system was constructed, and the volume ratio of the two liquid phases was designed to be 1:1. In order to reduce the liquid phase separation temperature and avoid Pb volatilization due to temperature, the Fe-Pb liquid Add C element (in the form of C-containing ductile iron) to the phase separation system, so that the composition of the Fe-rich region formed by liquid phase separation is near Fe-4.3%C (mass percentage, the same below), and control the Fe-Pb alloy melt temperature (1200°C ~ 1300°C), and then add a small amount of common metal eleme...

Embodiment 2

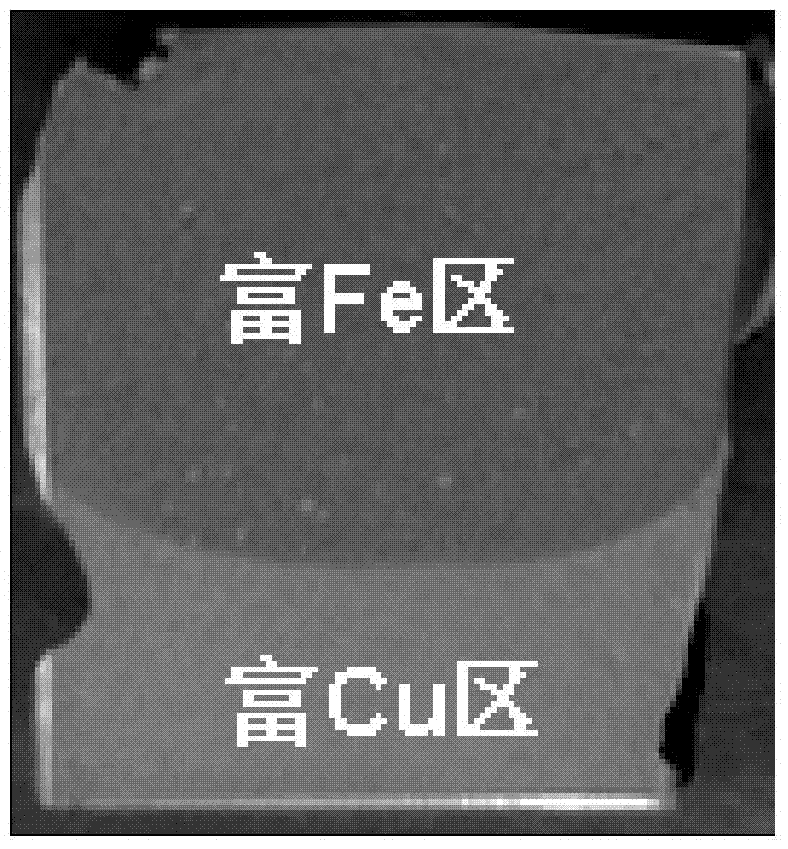

[0047] Purchase waste circuit boards of desktop computer motherboards, ductile iron with a carbon content of about 4%, and Pb ingots from the market. For waste circuit boards, first use crushing + crushing machinery to process waste circuit boards, and finally crush waste circuit boards into 0.1-0.5mm particles step by step, and then use the difference in physical properties between metal and non-metal (such as: the density of metal particles is greater than that of non-metal, Metal has conductivity, etc.), and the crushed waste circuit board particles are separated into metal particles and non-metal particles after multi-stage winnowing and high-voltage electrostatic separation. The X-ray fluorescence spectrometer is used to determine that the metal material is composed of 13 elements such as Al, Si, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ag, Sn, Sb, Au, Pb, etc., based on the main component of the metal material Fe , Cu, Pb, etc., first build a Fe-Cu high-temperature liquid phase separ...

Embodiment 3

[0051] Purchase waste circuit boards of desktop computer motherboards, ductile iron with a carbon content of about 4%, and Pb ingots from the market. For waste circuit boards, first use crushing + crushing machinery to process waste circuit boards, and finally crush waste circuit boards into 0.1-0.5mm particles step by step, and then use the difference in physical properties between metal and non-metal (such as: the density of metal particles is greater than that of non-metal, Metal has conductivity, etc.), and the crushed waste circuit board particles are separated into metal particles and non-metal particles after multi-stage winnowing and high-voltage electrostatic separation. The X-ray fluorescence spectrometer is used to determine that the metal material is composed of 13 elements such as Al, Si, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ag, Sn, Sb, Pb, etc., based on the main components of the metal material Fe, Cu , Pb, etc., first build a Fe-Cu high-temperature liquid phase separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com