Manufacturing method of micro-nano structure capable of accurately controlling depth

A micro-nano structure and precise control technology, applied in the manufacture of micro-structure devices, micro-structure technology, micro-structure devices, etc., can solve the problems of inability to meet the high-precision requirements of micro-nano devices, affecting the diffraction effect of the device, and reducing the uniformity of the light spot. , to achieve the effect of promoting wide application, realizing mass production, reducing production cost and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

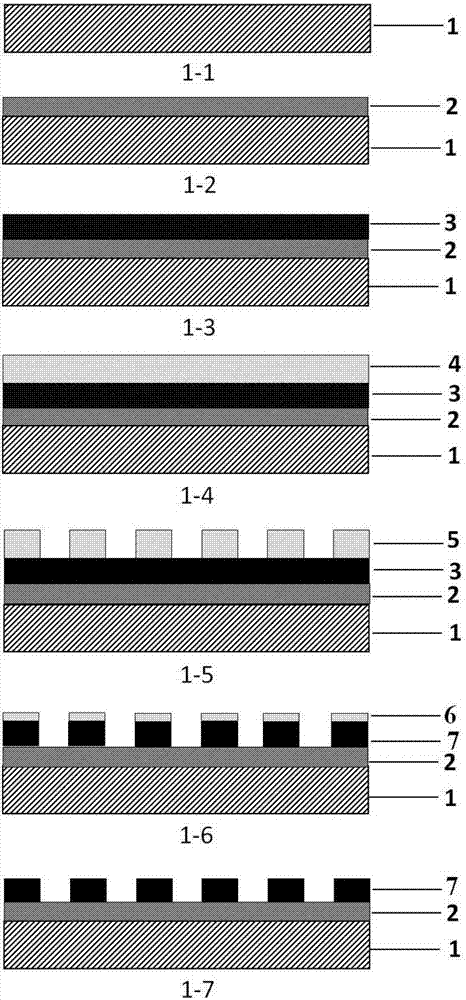

[0028] Such as figure 1 As shown in 1-1, take a polished glass substrate 1 with a thickness of 2 mm and an area of 3 cm x 3 cm, soak it in dilute nitric acid for more than 12 hours, remove the stain on the surface, take it out and put it in Ultrasonic cleaning in deionized water for use;

[0029] Such as figure 1 As shown in 1-2, since the gold material is resistant to reactive plasma etching of fluorine-based gases, a gold film 2 with a thickness of 305 nanometers is evaporated on the quartz substrate 1 by electron gun evaporation as an etching cut-off. layer;

[0030] Such as figure 1 As shown in 1-3, a silicon dioxide film 3 with a thickness of 900 nanometers is coated on the gold film 2 by magnetron sputtering, and the thickness of the film layer is detected online by an online quartz crystal film thickness measuring instrument. Accuracy is ±1 nanometer;

[0031] Such as figure 1 As shown in middle 1-4, use the glue leveler, set the rotation speed to 3000 rpm, spin...

example 2

[0035] Such as figure 2 As shown in 2-1, take an aluminum oxide substrate with a surface polishing thickness of 2 mm and an area of 3 cm × 3 cm as the etching stop layer 1, and clean the surface with acetone solution to remove the surface stains;

[0036] Such as figure 2 As shown in middle 2-2, a layer of silicon nitride material film 2 with a thickness of 1.8 microns is coated on the aluminum oxide substrate 1 by magnetron sputtering, and the thickness of the film layer is measured by an online quartz crystal film thickness measuring instrument. On-line detection, the thickness accuracy is ±1 nanometer;

[0037] Such as figure 2 As shown in middle 2-3, use a glue homogenizer, set the speed at 5000 rpm, spin-coat the photoresist AZ9260 on the surface of the silicon nitride film 2 to form a photoresist film layer 3 with a thickness of 2.537 microns, The accuracy of spin coating is ±3 nanometers;

[0038] Such as figure 2 As shown in 2-4, a photoresist grating struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com