Method for growing LED epitaxial structure with high-quality InGaN/GaN active layer

A technology of epitaxial structure and growth method, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as reducing luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

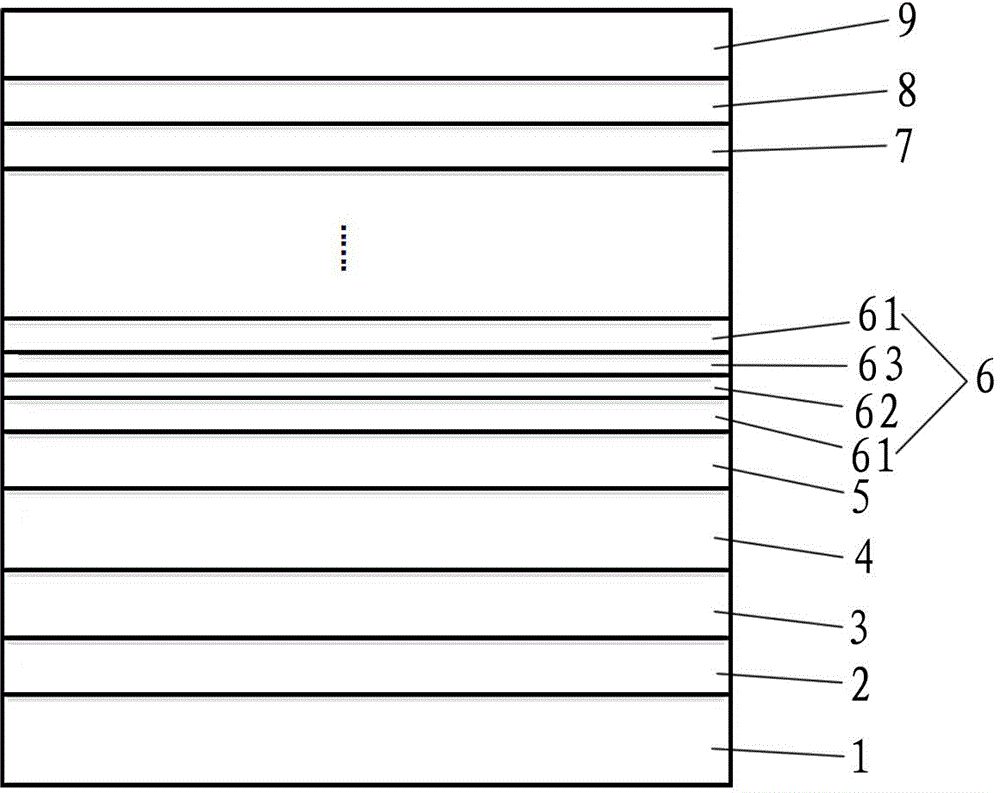

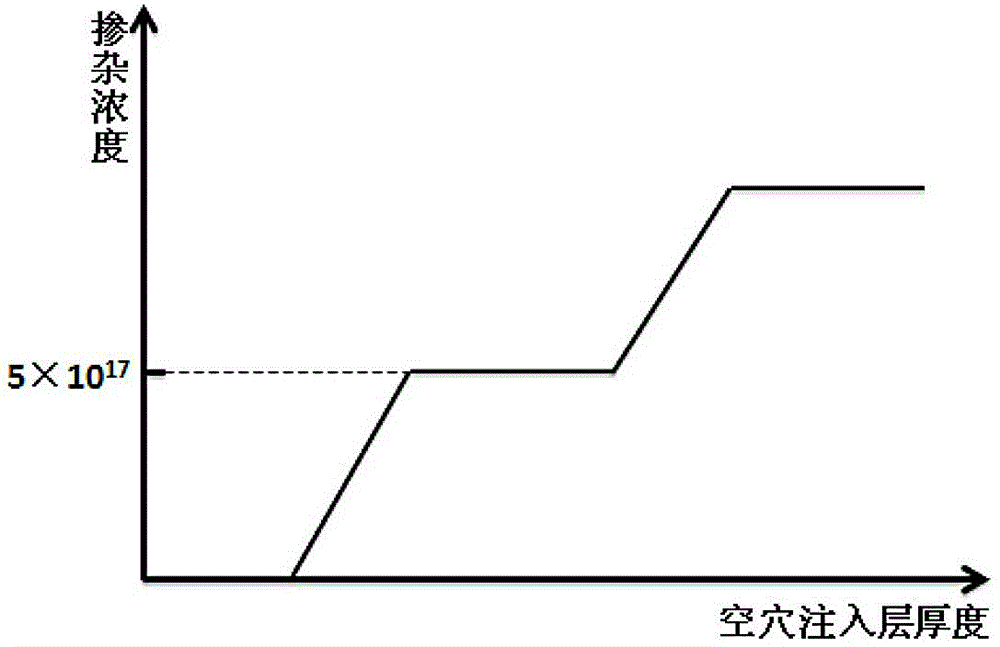

[0056] like figure 1 As shown, the present invention discloses an LED epitaxial structure with a high-quality InGaN / GaN active layer, on which a buffer layer 2, an unintentionally doped layer 3, an N-type doped layer 4, and a stress balance layer are sequentially grown on a substrate 1. Layer 5, In x Ga 1-x N / GaN active layer 6, hole injection layer 7, electron blocking layer 8 and P-type doped layer 9; In x Ga 1-x The N / GaN active layer 6 is composed of multiple sets of GaN quantum barrier layers 61 and In x Ga 1-x N quantum well layer 62 is formed. In each set of GaN quantum barrier layers 61 and In x Ga 1-x A GaN protective layer 63 is grown between the N quantum well layers 62 .

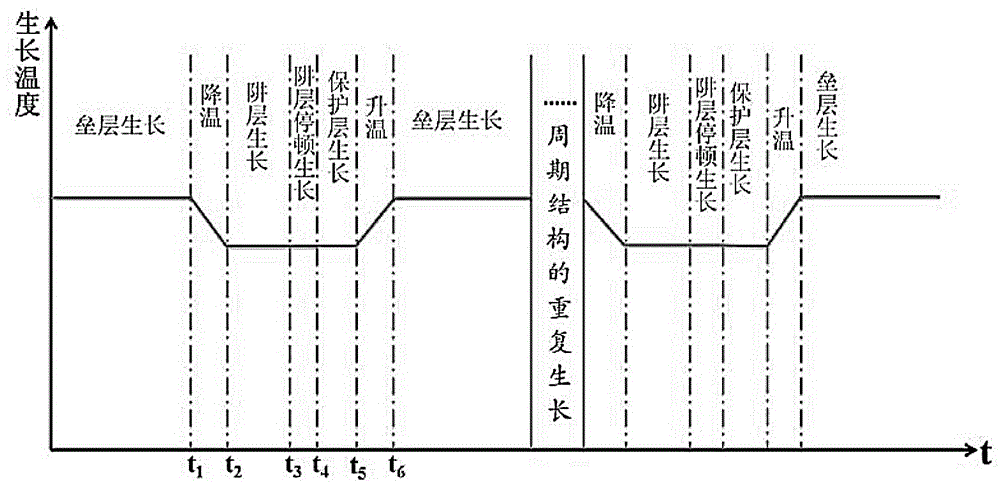

[0057] The present invention also discloses a method for growing an LED epitaxial structure with a high-quality InGaN / GaN active layer. On a substrate 1, a buffer layer 2, an unintentionally doped layer 3, an N-type doped layer 4, a stressed Balance layer 5, In x Ga 1-x N / GaN active la...

Embodiment 2

[0076] The difference from Embodiment 1 is that: Figure 5 As shown, a GaN / InGaN superlattice layer 10 is grown between the hole injection layer 7 and the electron blocking layer 8, through the growth of the superlattice layer 10, the crystal quality and hole concentration can be further improved.

[0077] In this embodiment, a method for growing an LED epitaxial structure with a high-quality InGaN / GaN active layer, a buffer layer 2, an unintentionally doped layer 3, an N-type doped layer 4, and a stress balance layer are sequentially grown on a substrate 1. Layer 5, In x Ga 1-x N / GaN active layer 6, hole injection layer 7, electron blocking layer 8 and P-type doped layer 9, GaN / InGaN superlattice layer 10 is grown between hole injection layer 7 and electron blocking layer 8; wherein, In x Ga 1-x The growth of N / GaN active layer 6 comprises the following steps:

[0078] Using MOCVD equipment to epitaxially grow high-brightness green light-emitting diodes, a 2-inch c-plane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com