Method for preparing molecularly-imprinted monolithic column by using molecular crowding reagent and ionic liquid as pore-foaming agent

A technology of crowding reagents and ionic liquids, applied in the field of preparing molecularly imprinted monolithic columns, can solve problems such as immiscibility, and achieve the effects of good identification performance, good permeability and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

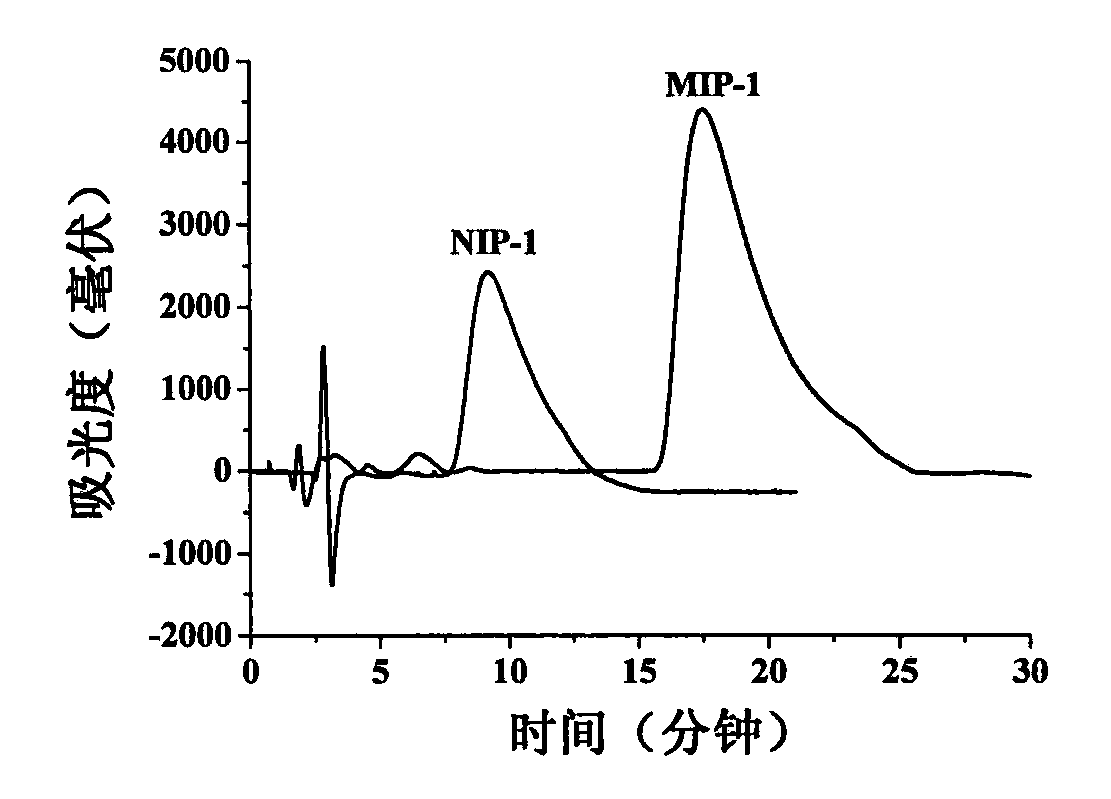

[0025] Preparation of ursolic acid molecularly imprinted monolithic column using polymethyl methacrylate and ionic liquid as porogens and evaluation of imprinting effect:

[0026] a. The template molecule ursolic acid is added into a chloroform solution made of polymethyl methacrylate as a macromolecular crowding reagent, and 1-butyl-3-methyl-imidazole tetrafluoroborate and dimethyl sulfoxide as an ionic liquid. In a porogen with a volume ratio of 25:8:5, sonicate until the template is completely dissolved to form a complex;

[0027] b. Add functional monomer 4-vinylpyridine, cross-linking agent ethylene glycol dimethacrylate and initiator azobisisobutyronitrile to the compound formed in step a, degas it by ultrasonic for 10 minutes, and pass nitrogen gas for 10 minutes to remove Oxygen, and then inject the mixed solution into the stainless steel chromatographic column with a column length of 100 mm and an inner diameter of 4.6 mm. The molar ratio of the functional monomer an...

Embodiment 2

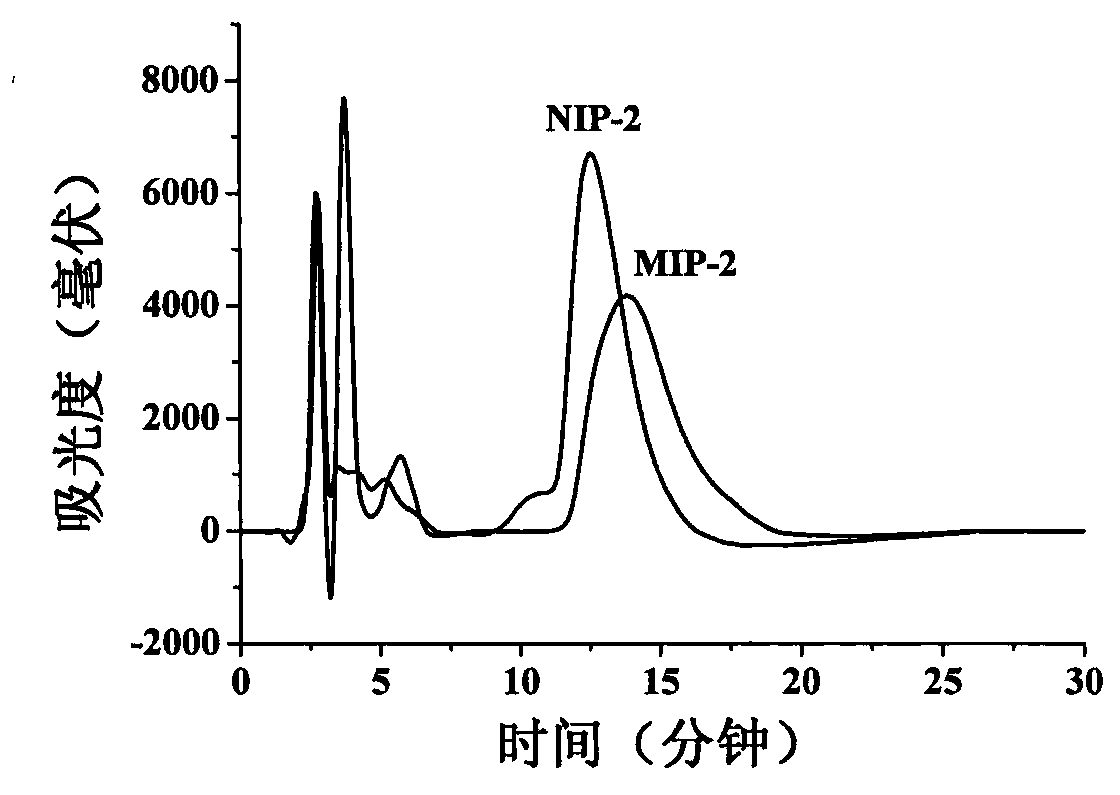

[0031] Embodiment 2 (contrast)

[0032] In order to investigate the influence of polymethyl methacrylate on the synthesis method, a ursolic acid molecularly imprinted monolithic column without adding polymethyl methacrylate was synthesized, and the specific steps are as follows:

[0033]a, the template molecule ursolic acid is added to the porogen composed of 1-butyl-3-methyl-imidazolium tetrafluoroborate and dimethyl sulfoxide in a volume ratio of 8:5, and ultrasonicated until The template is completely dissolved to form a complex;

[0034] b. Add functional monomer 4-vinylpyridine, cross-linking agent ethylene glycol dimethacrylate and initiator azobisisobutyronitrile to the compound formed in step a, degas it by ultrasonic for 10 minutes, and pass nitrogen gas for 10 minutes to remove Oxygen, and then inject the mixed solution into the stainless steel chromatographic column with a column length of 100 mm and an inner diameter of 4.6 mm. The molar ratio of the functional m...

Embodiment 3

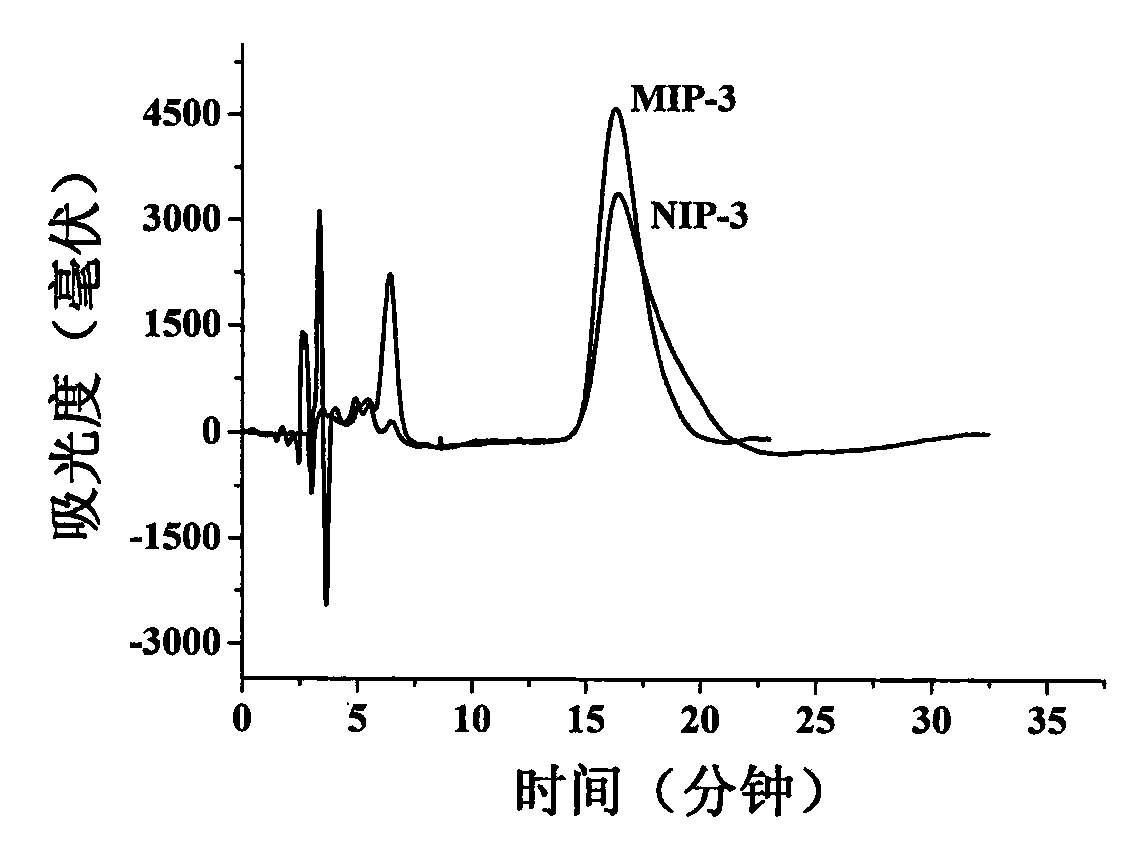

[0038] Embodiment 3 (contrast)

[0039] In order to investigate the influence of ionic liquids on the synthesis method, a molecularly imprinted monolithic column of ursolic acid was synthesized with isooctane instead of ionic liquids. The specific steps are as follows:

[0040] a. The template molecule ursolic acid is added to the porogen composed of a chloroform solution of polymethyl methacrylate as a macromolecular crowding agent, and an ionic liquid of isooctane and dimethyl sulfoxide in a volume ratio of 25:8:5. In the reagent, sonicate until the template is completely dissolved to form a complex;

[0041] b. Add functional monomer 4-vinylpyridine, cross-linking agent ethylene glycol dimethacrylate and initiator azobisisobutyronitrile to the compound formed in step a, degas it by ultrasonic for 10 minutes, and pass nitrogen gas for 10 minutes to remove Oxygen, and then inject the mixed solution into the stainless steel chromatographic column with a column length of 100 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com