Assembled type prestressed aluminum alloy single-layer latticed shell structure

A single-layer reticulated shell and prestressed technology, which is applied to arch structures, dome structures, building components, etc., can solve problems such as poor stability, increased structural construction costs, and impacts, and achieve improved bearing capacity, reduced consumption, and The effect of saving the number of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described below in conjunction with the accompanying drawings and examples.

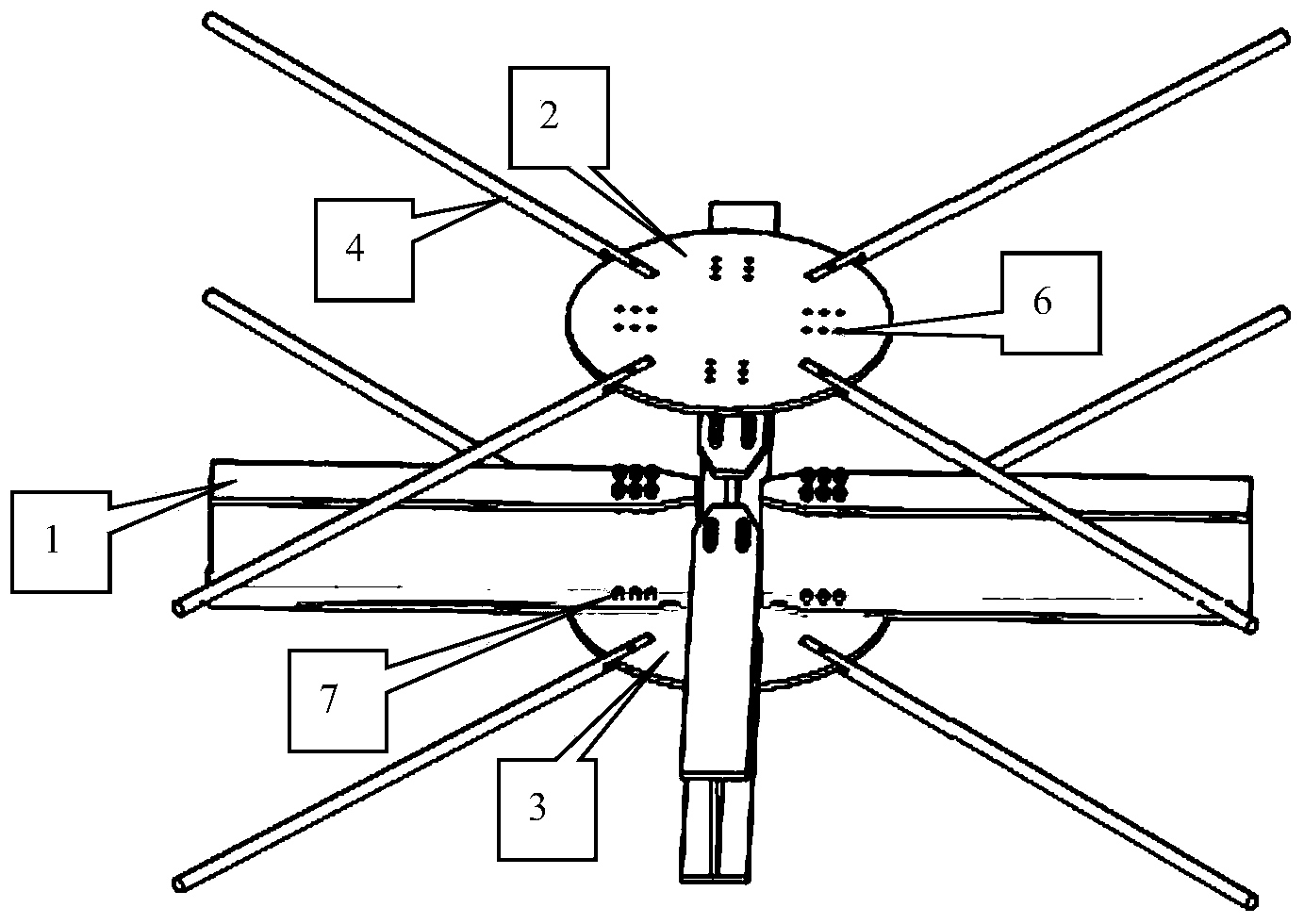

[0012] like figure 1 As shown, the assembled prestressed aluminum alloy single-layer reticulated shell structure in this example includes cables 4 , rods 1 , and nodes 8 . The new plate joint 8 used in this structure includes H-shaped bar 1 , upper disc cover 2 , lower disc cover 3 , stay cables 4 , and bolts 7 .

[0013] In this node 8, the upper flange of the H-shaped steel member 1, the upper disc cover 2 and the bolt holes 6 must correspond; the lower flange of the H-shaped steel member 1, the lower disc cover 3 and the bolt holes 6 must correspond ; The bolt holes 6 of the cable 4 and the upper disk cover plate 2 must correspond. When installing the new plate type node 8, first connect the H-shaped steel rod 1 with the upper disc cover 2 and the lower disc cover 3 with bolts 7, and then connect the cable 4 with the upper disc cover 2 and the diagonal The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com