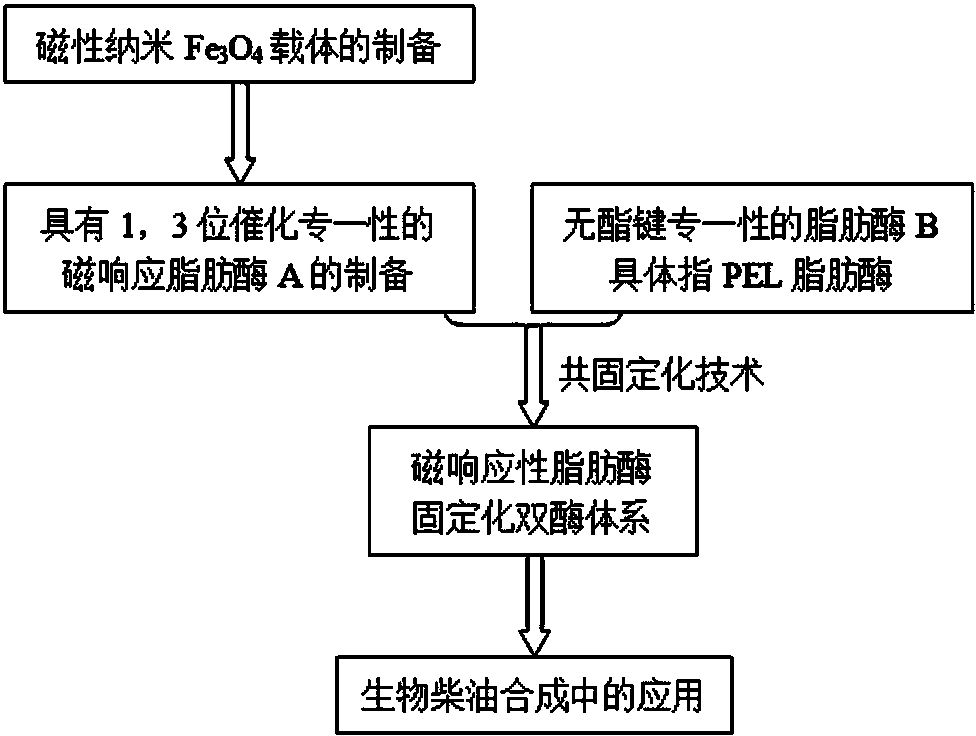

Preparation method of magnetic response composite lipase and application in biodiesel synthesis

A composite lipase, magnetic responsive technology, applied in biofuels, immobilized on or in inorganic carriers, immobilized on/in organic carriers, etc., can solve the needs of industrial production, enzyme loss of enzymes, etc. Activity, poor stability and other problems, to achieve the effect of improving enzyme transesterification efficiency, reducing enzyme dosage, and improving transesterification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

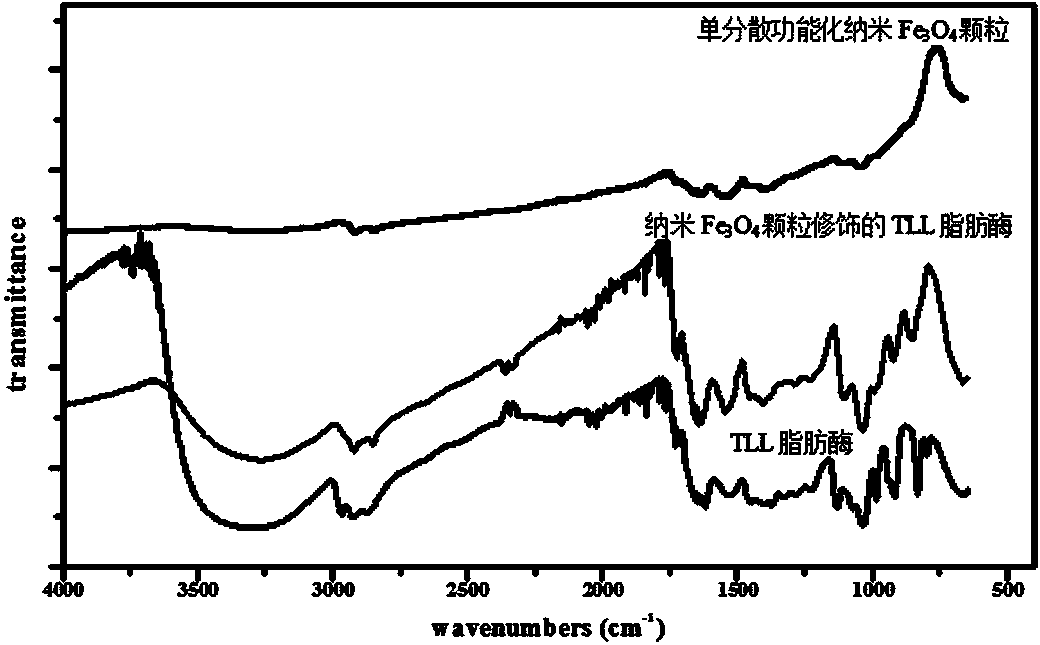

[0030]Example 1 Preparation of magnetically responsive lipase A with 1,3 position specificity

[0031] Specifically refers to the use of 10nm nano-Fe 3 o 4 Particle-modified Thermomyces lanuginosus lipase (Lipase from Thermomyces lanuginosus , TLL) preparation: Take 1mL nano-Fe with carboxyl functional groups on the surface 3 o 4 solution (10nm, iron content 155mg / L), add 10μL of 10mmol / L carbodiimide (1-Ethyl-3-[3-dimethylaminopropyl]carbodiimide, EDC) solution and 25mmol / L N- Hydroxysulfosuccinimide ( N -hydroxysulfosuccinimide, Sulfo-NHS) solution, shaking reaction at room temperature for 10min, and centrifuging to collect the nano-Fe after carboxyl activation 3 o 4 Particles; the activated nano-Fe 3 o 4 The particles were added to 200 μL of TLL lipase solution with a concentration of 5 mg / mL, shaken at room temperature for 2 hours, magnetically separated, washed repeatedly with distilled water, removed uncoupled free lipase, and collected nano-Fe 3 o 4 Granule-l...

Embodiment 2

[0032] Example 2 Preparation of magnetically responsive lipase A with 1,3 position specificity

[0033] Specifically refers to the use of 10nm nano-Fe 3 o 4 Particle-modified Pseudomonas fluorescens lipase (Lipase from Pseudomonas fluorescens , PLL) preparation: Take 1 mL of nano-Fe with carboxyl functional groups on the surface 3 o 4 solution (10nm, iron content 155mg / L), add 10μL EDC solution with a concentration of 10mmol / L and Sulfo-NHS solution with a concentration of 25mmol / L, shake and react at room temperature for 10min, and centrifuge to collect nano-Fe after carboxyl activation 3 o 4 Particles; the activated nano-Fe 3 o 4 The particles were added to 200 μL of PFL lipase solution with a concentration of 1 mg / mL, shaken at room temperature for 2 hours, magnetically separated, washed repeatedly with distilled water, removed uncoupled free lipase, and collected nano-Fe 3 o 4 Granule-lipase complex.

Embodiment 3

[0034] Example 3 Preparation of magnetically responsive lipase A with 1,3 position specificity

[0035] Specifically refers to the use of 15nm nano-Fe 3 o 4 Particle-modified Thermomyces lanuginosus lipase (Lipase from Thermomyces lanuginosus , TLL) preparation: Take 1mL nano-Fe with carboxyl functional groups on the surface 3 o 4 Solution (15nm, iron content 100mg / L), add 10μL of EDC solution with a concentration of 10mmol / L and 20μL of Sulfo-NHS solution with a concentration of 25mmol / L, shake and react at room temperature for 30min, centrifuge to collect carboxyl-activated Nano Fe 3 o 4 Particles; the activated nano-Fe 3 o 4 Particles were added to 1 mL of 5 mg / mL Thermomyces lanuginosus In the lipase solution, shake and react at room temperature for 2 hours, magnetically separate, wash repeatedly with distilled water, remove uncoupled free lipase, and collect nano-Fe 3 o 4 Granule-lipase complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com