A heat-resistant and impact-resistant polyvinyl chloride-poly-1-butene compound and its preparation method

A polyvinyl chloride and compound technology, which is applied in the field of polyvinyl chloride compound preparation, can solve the problems of low thermal deformation temperature, poor weather resistance, poor thermal stability, etc., and achieve comprehensive performance improvement, good heat resistance, and resistance to High impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

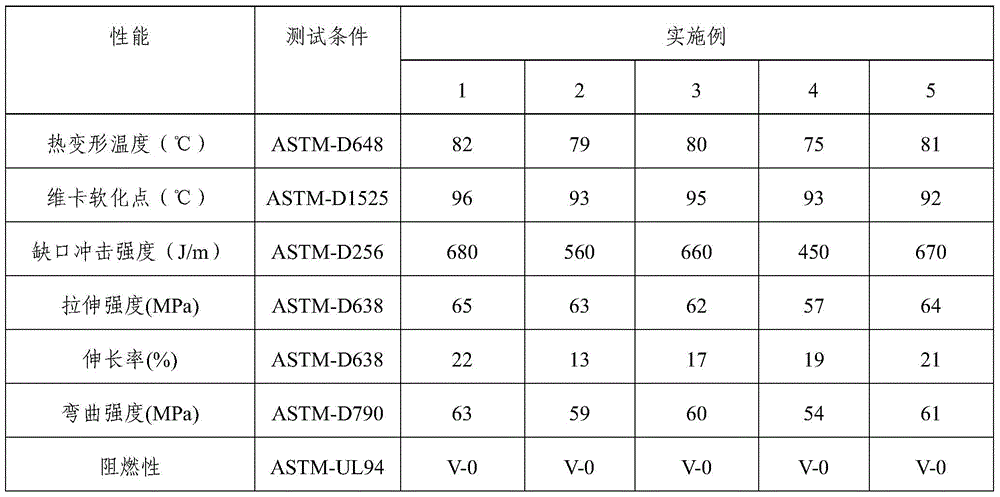

Examples

preparation example Construction

[0031] The preparation method of polyvinyl chloride-poly-1-butene compound of the present invention comprises the following steps:

[0032] 1) In parts by weight, add 70 to 90 parts of polyvinyl chloride and 1 to 3 parts of rare earth-epoxy composite stabilizer into a high-speed mixer with a rotation speed of 800 to 1000 rpm, and mix until the material temperature is 50 to 60 ℃, then add 1-5 parts of compatibilizer and 1-10 parts of internal lubricant in turn, mix to 70-80 ℃, add 0.5-2 parts of external lubricant, mix to 90-100 ℃, add 10-30 parts of poly 1-butene, 5-10 parts of rigid nanoparticles, mixed to 110-120 ° C, discharged and cooled to obtain a polyvinyl chloride-poly-1-butene mixture;

[0033] 2) Add the polyvinyl chloride-poly-1-butene mixture into the conical twin-screw extruder. Under the conditions of 130-170°C and screw speed of 4-30 rpm, it is melt-extruded and pelletized to obtain a rigid polyvinyl chloride-poly-1-butene compound that is environmentally frien...

Embodiment 1

[0036] Add 70 parts by weight of polyvinyl chloride with a degree of polymerization of 1300, 1 part by weight of lanthanum stearate and a composite stabilizer with a weight ratio of 7:3 to epoxy soybean oil into a high-speed mixer, mix to 50 ° C, add a compatibilizer 2 parts by weight of chlorinated polyethylene (CPE) and 1 part by weight of calcium stearate were mixed to 70°C, 0.5 parts by weight of microcrystalline paraffin was added and mixed to 90°C, and 30 parts by weight of Mitsui PB0100 poly-1-butene was added (the isotactic structure content is 96%), the nano-calcium carbonate that 5 weight parts of silane coupling agents are processed, mix to 110 ℃, discharge cooling, obtain polyvinyl chloride-poly-1-butene mixture; The poly-1-butene mixture is fed into the conical twin-screw extruder, and melted at the temperature of the first zone of 140°C, the temperature of the second zone of 148°C, the temperature of the third zone of 152°C, the temperature of the fourth zone of 1...

Embodiment 2

[0038] Add 80 parts by weight of polyvinyl chloride with a degree of polymerization of 1500, 1 part by weight of lanthanum stearate and a composite stabilizer with a weight ratio of 7:3 to epoxy soybean oil into a high-speed mixer, mix to 50 ° C, add a compatibilizer 2 parts by weight of chlorinated polyethylene (CPE) and 1 part by weight of calcium stearate were mixed to 70°C, 1 part by weight of microcrystalline paraffin was added and mixed to 90°C, and 20 parts by weight of poly-1-butene of Mitsui PB0100 was added (the isotactic structure content is 96%), the nano-calcium carbonate that 5 weight parts of silane coupling agents are processed, mix to 110 ℃, discharge cooling, obtain polyvinyl chloride-poly-1-butene mixture; The poly-1-butene mixture is added to the conical twin-screw extruder, and melted under the conditions of the first zone temperature of 150°C, the second zone temperature of 156°C, the third zone temperature of 162°C, the fourth zone temperature of 158°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com