Glass substrate composition for incineration ash of combustible wastes with low and medium-level radioactivity, and glass curing body prepared from glass substrate composition

A glass matrix and vitrification technology, which is applied in glass manufacturing equipment, glass forming, manufacturing tools, etc., can solve the problems of special waste and complex high-level waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Determination of the main simulated components of the incineration ash of medium and low level radioactive combustible waste

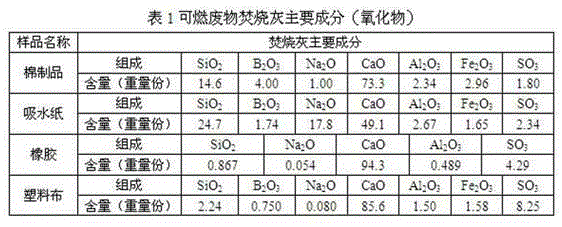

[0077] A holistic consideration of the oxide composition in radioactive waste. It mainly simulates the oxide and nuclide composition of the remaining ash after incineration of absorbent paper, cotton product labor insurance, plastic cloth and rubber gloves in nuclear power plants. The main oxide content is obtained by chemical analysis, and the radionuclides are mainly considered fission products 137 Cs, 90 Sr and activation products 60 Co. The composition and content of the simulated waste are shown in Table 1 below.

[0078]

[0079] Among them, the data in the above table 1 is obtained on the basis of 100 parts by weight of each combustible waste incineration ash, and the CoO and Cs in the various simulated waste incineration ash are not listed in the above table 1 2 The contents of O and SrO are respectively 0.2wt% of the total amoun...

Embodiment 2-4

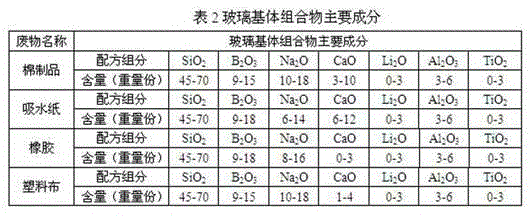

[0091] The treatment method of low-medium level radioactive cotton products: Weigh the corresponding raw materials for the components listed in the above table 1 and the following table 3 according to the proportion, and weigh 100 parts by weight of the glass matrix composition (according to the oxide Calculate), and weigh 60 parts of simulated waste (calculated by oxide) at the same time. The ingredients are ground and mixed evenly, put into corundum crucible, and sent to a box-type resistance furnace preheated to above 300°C for melting. Keep the temperature at 1100-1300°C for 2-5h, then pour it into a graphite tube that has been preheated at 400-600°C, then anneal in an annealing furnace at this temperature, and cool naturally in the furnace to room temperature.

[0092]

Embodiment 5-6

[0094] Treatment methods for medium and low level radioactive absorbent paper:

[0095] Weigh the corresponding raw materials for the components listed in the above Table 1 and the following Table 4 in parts by weight according to the proportion. For every 100 parts by mass of the glass matrix composition (calculated as oxides), 50 parts by mass of simulated waste (calculated as oxides) were weighed at the same time. The raw materials are finely ground in a mortar, mixed carefully, put into a corundum crucible, and sent to a box-type resistance furnace preheated to above 300°C for melting. Keep the temperature at 1100-1300°C for 2-5h, then pour it into a graphite tube that has been preheated at 400-600°C, then anneal in an annealing furnace at this temperature, and cool naturally in the furnace to room temperature.

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com