A heating furnace used for drawing willow glass by secondary melting method

A flexible and secondary melting technology of far drawing, which is applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of no heating furnace, description, etc., and achieve good flatness, small thickness deviation, and high temperature The effect of small fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

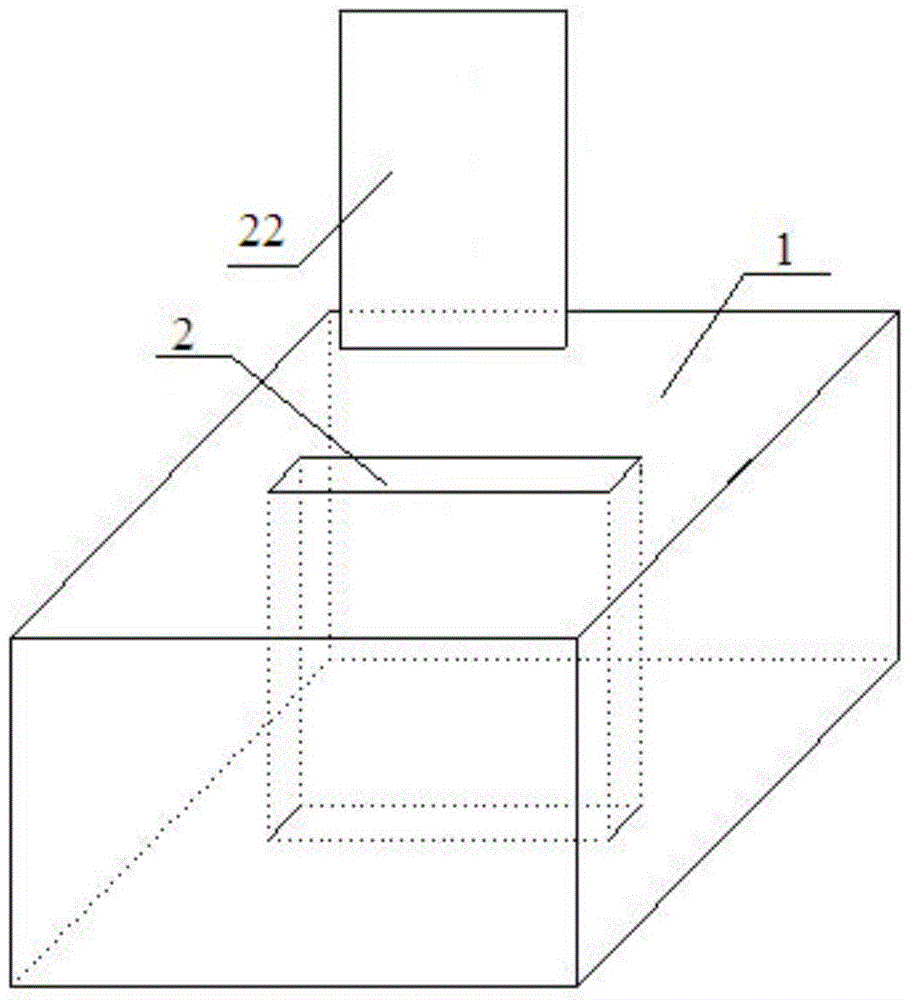

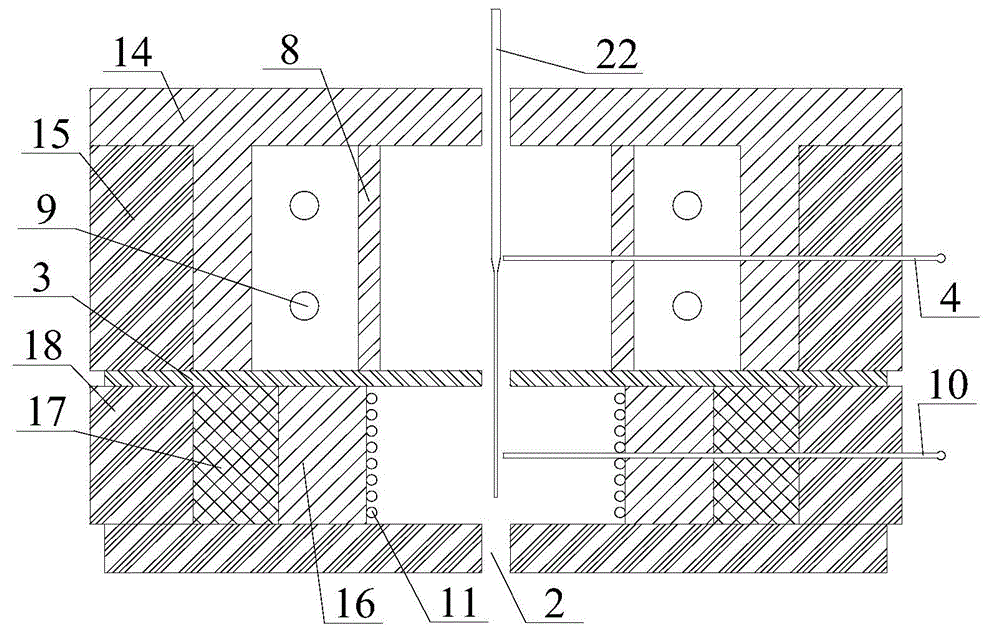

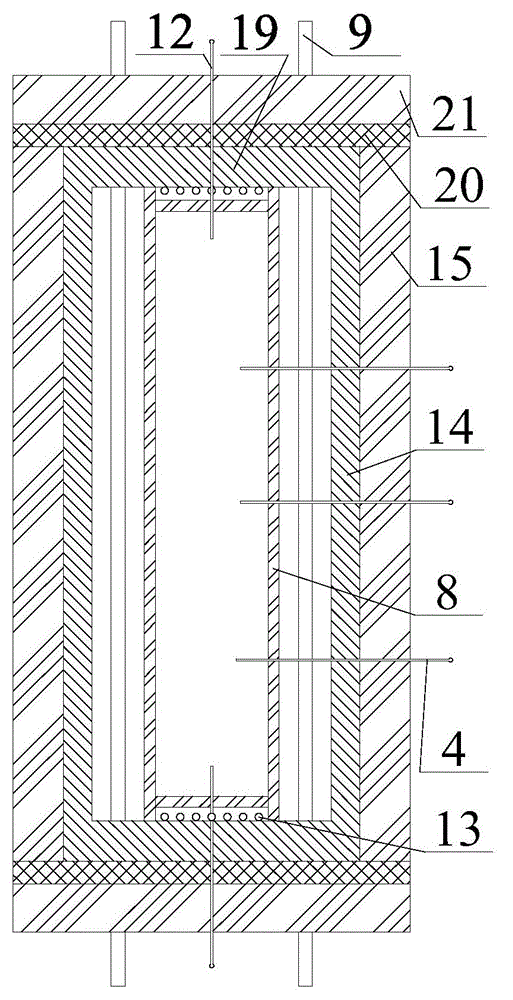

Embodiment 1

[0038] Embodiment 1. A heating furnace for drawing flexible glass by the secondary melting method is divided into a high temperature zone and an annealing zone, which are separated by a light heat insulating thin plate 3, and the width between the thin plates on both sides is 10mm. The high temperature area is heated by two silicon carbide heating rods, and the length of the hot end of the heating rod and the furnace is 600mm. The length and height of the long board in the vapor chamber 8 combination are 660mm and 200mm respectively, and the width and height of the short board are 50mm and 200mm respectively. The rated power of the high temperature area is 5kW; the rated power of the temperature compensation filling blocks at both ends is 1kW, and the material of the heating wire is nickel-chromium Ni80Cr20 alloy. The furnace body materials used on both sides of the high temperature zone are 50mm thick polycrystalline mullite fiber cotton and 65mm thick lightweight insulation ...

Embodiment 2

[0041] Embodiment 2. A heating furnace for drawing flexible glass by the secondary melting method, which is divided into a high temperature zone and an annealing zone, which are separated by light heat insulating thin plates 3, and the width between the thin plates on both sides is 20 mm. The high temperature area is heated with 4 silicon carbide heating rods, and the length of the hot end of the heating rod and the furnace is 400mm. The length and height of the long boards in the vapor chamber 8 combination are 460mm and 100mm respectively, and the width and height of the short boards are 80mm and 100mm respectively. The rated power of the high temperature area is 10kW; the rated power of the temperature compensation filling blocks at both ends is 2kW, and the heating wire is made of iron-chromium-aluminum 0Cr23Al5 alloy. The furnace body materials used on both sides of the high temperature zone are 100mm thick polycrystalline mullite fiber cotton and 130mm thick lightweight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com