Device and method for continuously removing suspended matters in crude oil

A suspension and removal technology, applied in the field of petrochemical industry, can solve problems such as incomplete removal, affecting desalination effect, easy to block devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

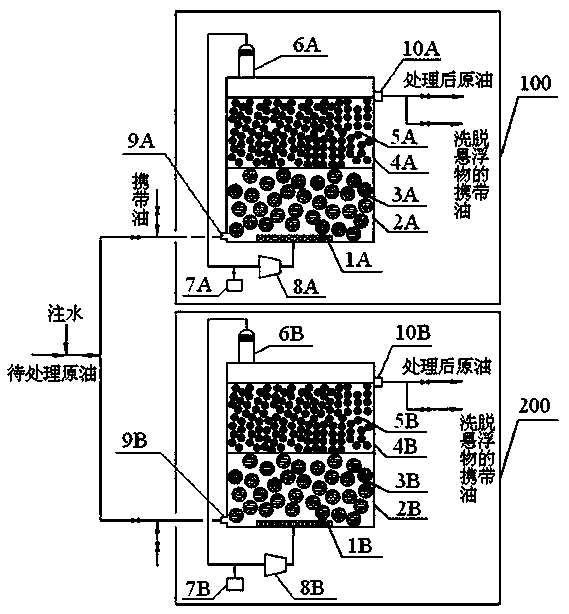

[0035] A device for continuously removing suspended solids in crude oil, such as figure 1 As shown, the air flotation removal system Ⅰ100 and the air flotation removal system Ⅱ200 are included. The air flotation removal system Ⅰ100 includes a first-level air-flotation removal section 2A and a second-level air-flotation removal section 4A arranged sequentially from bottom to top. The first-level air flotation removal section 2A is filled with a first-level air-floating packing layer 3A, the packing is macroporous honeycomb packing, and the density is 550kg / m 3 , The porosity is 65%~70%; the secondary air flotation removal section 4A is filled with the secondary air flotation packing layer 5A, the packing is macroporous honeycomb packing, and the density is 570kg / m 3 , The porosity is 25%-30%; the above-mentioned fillers are all polypropylene fillers; the bottom of the first-stage air flotation removal section 2A is provided with a micro-bubble generator 1A, and the inlet of the mi...

Embodiment 2

[0039] A device for continuously removing suspended solids in crude oil, except that the porosity of the first-stage air-floating packing layers 3A and 3B is 75% to 80%, and the porosity of the second-stage air-floating packing layers 5A and 5B is 30% to 35%. Other structure and arrangement are the same as in Example 1.

Embodiment 3

[0041] The device for removing suspended solids in oil, except for the first-level air-floating packing layers 3A and 3B, which are filled with macroporous wire mesh, the porosity is 65% to 70%, and the porosity of the second-level air-floating packing layers 5A and 5B are Except for 20% to 25%, other structures and settings are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com