Device and method for crude oil suspended matter removal and oil-water separation coupling

A technology for oil-water separation and suspended solids, which is used in the petroleum industry and the treatment of hydrocarbon oil, and can solve problems such as reduced treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

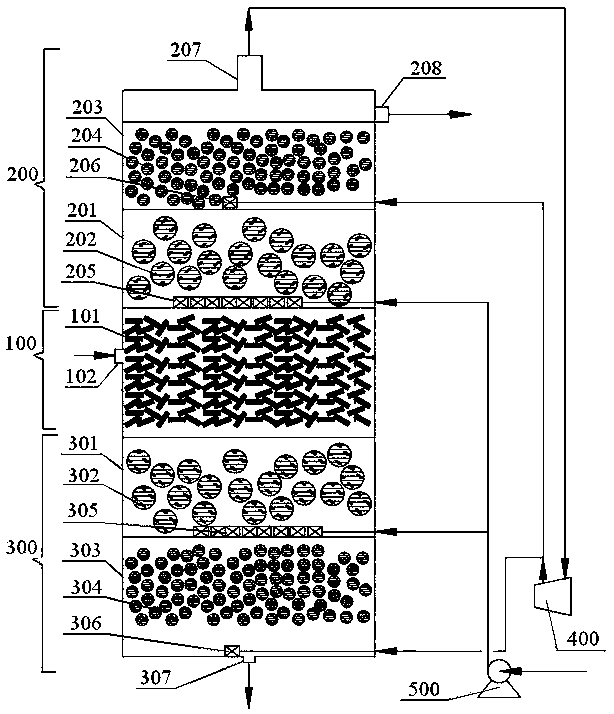

[0040] A device coupled with crude oil desuspension and oil-water separation, such as figure 1 As shown, it includes a light phase air flotation removal system 200, an oil-water separation system 100 and a heavy phase air flotation removal system 300 arranged in sequence from top to bottom;

[0041] The oil-water separation system 100 includes an oil-water separation packing layer 101, which is filled with a coalescence separation packing, and its side is provided with a crude oil feed port 102 to be treated; the coalescence separation packing is made of polypropylene and polypropylene fibers at a ratio of 1:2 Proportionally mixed and woven into 8-type filler monomers with dense concave-convex structure, and then assembled into rod-shaped fillers with a length of 5 mm, filled in the oil-water separation filler layer 101 in a free bulk and non-fixed state. The light-phase air flotation removal system 200 includes two-stage light-phase air flotation removal sections, the lower l...

Embodiment 2

[0044] Crude oil desuspension and oil-water separation coupling device, except for the first-stage light-phase air-flotation packing layer 202 and the first-stage heavy-phase air-flotation packing layer 302, the porosity of the packing is 60% to 65%, and the second-stage light-phase air-flotation packing The porosity of the filler in the layer 204 and the secondary heavy-phase air-floating filler layer 304 is 25% to 30%, and other structures and arrangements are the same as in Embodiment 1.

Embodiment 3

[0046] Crude oil desuspension and oil-water separation coupling device, except for the porosity of the first-stage light-phase air-floatable packing layer 202 and the first-stage heavy-phase air-floatable packing layer 302, the porosity of the packing is 65% to 70%, and the second-stage light-phase air-floatable packing layer The porosity of the filler in the layer 204 and the secondary heavy-phase air-floating filler layer 304 is 20% to 25%, and other structures and arrangements are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com