Device and method for continuous removal of suspended solids in crude oil

A suspension and removal technology, applied in the field of petrochemical industry, can solve the problems of incomplete removal, easy blockage of devices, and influence on desalination effect, so as to prevent the decline of adsorption efficiency or even blockage by suspended matter, and ensure the effect of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

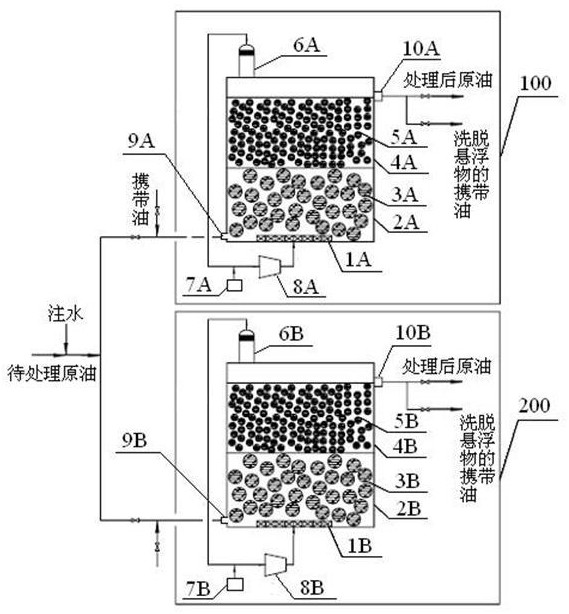

[0035] A device for continuously removing suspended matter in crude oil, such as figure 1 As shown, it includes air flotation removal system I100 and air flotation removal system II200. Air flotation removal system I100 includes a first-stage air flotation removal section 2A and a second-stage air flotation removal section 4A arranged in sequence from bottom to top. The primary air flotation removal section 2A is filled with a primary air flotation packing layer 3A, and the packing is macroporous honeycomb packing with a density of 550kg / m 3 , with a porosity of 65% to 70%; the secondary air flotation removal section 4A is filled with a secondary air flotation filler layer 5A, and the filler is a macroporous honeycomb filler with a density of 570kg / m 3 , with a porosity of 25% to 30%; the above fillers are all polypropylene fillers; the bottom of the primary air flotation removal section 2A is provided with a microbubble generator 1A, and the inlet of the microbubble generator...

Embodiment 2

[0039] The device for continuous removal of suspended solids in crude oil, except that the porosity of the primary air flotation packing layers 3A and 3B is 75% to 80%, and the porosity of the secondary air flotation packing layers 5A and 5B is 30% to 35%. Other structures and arrangements are the same as in Embodiment 1.

Embodiment 3

[0041] The device for removing suspended solids in oil products, except that the primary air flotation packing layers 3A and 3B are macroporous wire mesh packing with a porosity of 65% to 70%, and the porosity of the secondary air flotation packing layers 5A and 5B is Except 20%~25%, other structure and arrangement mode are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com