Light diffusing agent and preparation method thereof, and application of light diffusing agent

A technology of light diffusing agent and diffusing powder, which is applied in the direction of semiconductor devices, electrical components, circuits, etc. It can solve the problems of large distance between lamp beads and light crosstalk, and achieve the effects of ensuring quality, preventing light crosstalk, and reducing graininess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the light diffusing agent provided by the second aspect of the present application can obtain the light diffusing agent by mixing and grinding the raw material components of the formulated amount of the light diffusing agent. The preparation process is simple, and it is suitable for large-scale industrial production and application.

[0051] In some embodiments, the step of mixing and grinding includes: mixing and grinding each raw material component in the formulation amount for 10 to 60 minutes, so that each raw material component is uniformly dispersed, and the powder is further refined and homogenized. The size of the particles is improved to improve the stability of the slurry, and then vacuumed 2 to 3 times to remove the air bubbles in the slurry, so as to avoid the occurrence of air bubbles in the film layer during subsequent coating and use, and obtain a light diffusing agent.

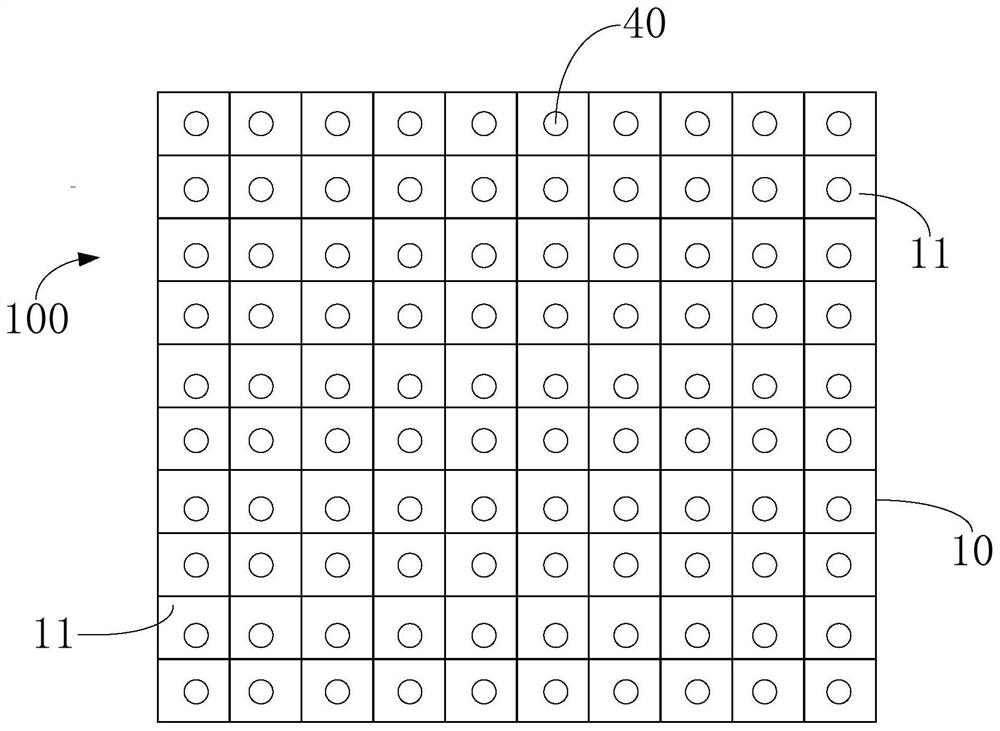

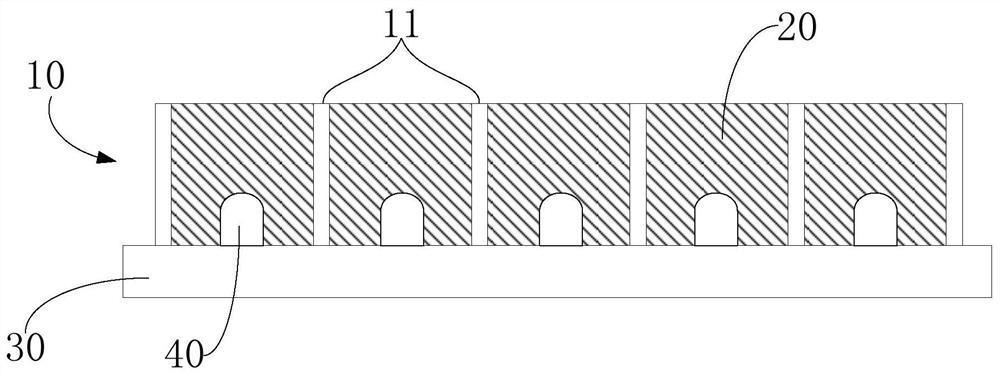

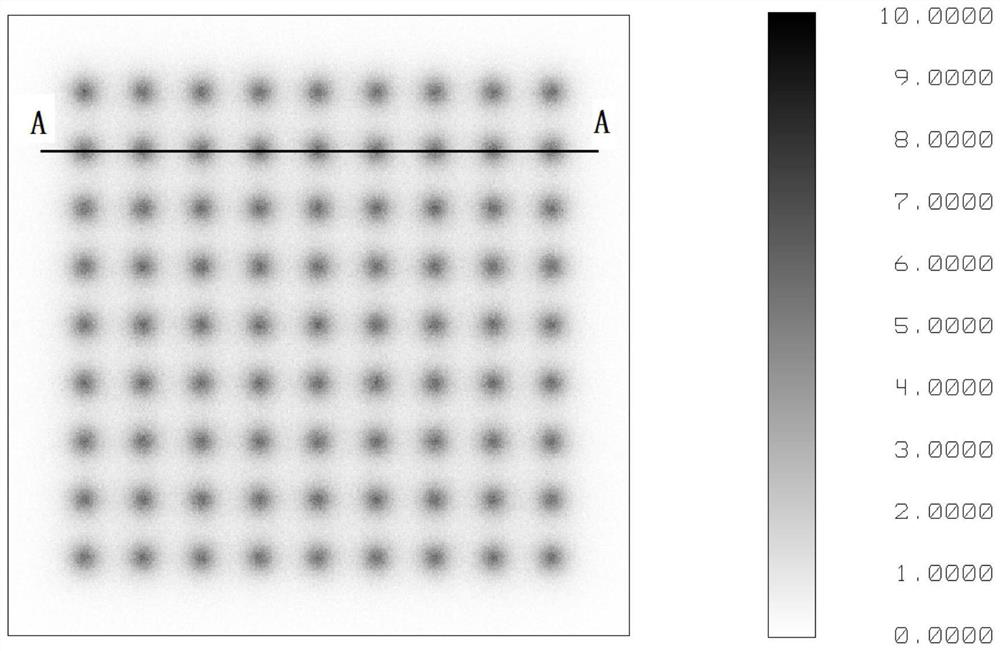

[0052] The third aspect of the embodiment of the present ap...

Embodiment 1

[0060] A kind of light diffusing agent, its preparation step comprises:

[0061] Mix inorganic silicone resin microspheres with an average particle size of 4 μm and a refractive index of 1.49 with silica gel glue (AB glue) with a light refractive index of 1.403-1.54 in a ratio of 1:5, and grind after mixing After 10 minutes, the first light diffusing agent was obtained.

[0062] After the preparation is completed, samples are taken for ultraviolet-visible absorption spectrum testing, and the light transmittance of the above-mentioned first light-diffusing agent is measured to be 95%-98%; a viscometer is used for testing, and the mixed viscosity of the above-mentioned first light-diffusing agent is measured At 3000-4800mpa.s.

Embodiment 2

[0064] A kind of light diffusing agent, its preparation step comprises:

[0065] Mix aluminum oxide particles with an average particle size of 6 μm and a refractive index of 1.49 with UV glue with a light refractive index of 1.403-1.54 in a ratio of 2:5, and grind for 10 minutes after mixing to obtain The second light diffuser.

[0066] After the preparation is completed, samples are taken for ultraviolet-visible absorption spectrum testing, and the light transmittance of the above-mentioned second light diffusing agent is measured to be 95%-99%. The mixed viscosity is 3000-4800mpa.s when tested with a viscometer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com