An energy-saving kiln with circular moving plates

A plate-moving and ring-shaped technology, applied in the field of ring-moving plate energy-saving kilns, can solve the problems of frequent failures of push-plate kilns, excessive heat loss of tunnel kilns, and short overhaul period, and achieve labor saving, compact structure and energy saving. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

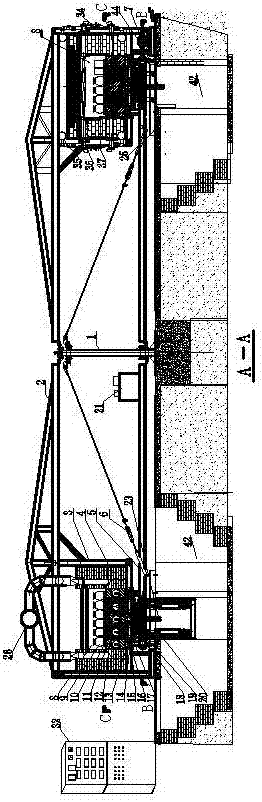

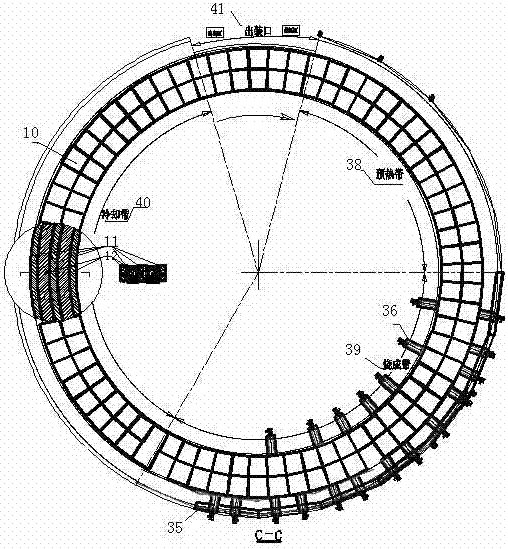

[0023] According to the sintering temperature of the product to be roasted, select a suitable heat-resistant material. Determine the cross-sectional area and diameter of the kiln according to the output size and product height. According to the factory building, topography, and location, lay a solid foundation, strictly calibrate the ground and foundation, and manufacture and install: the kiln body frame and the kiln bottom frame need to be cut to length and welded according to the tire mold. If the distance between the kiln bottom and the kiln wall is less than 3 mm, a scraper must be installed on the turntable to achieve this precision. Debugging; adjust the predetermined speed through the frequency regulated by the frequency converter; determine the pressure of the burner and the amount of combustion-supporting air according to the sintering temperature. After setting the value on the smart meter, the kiln can be automatically adjusted to ensure that the temperature is stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com