A type of motor mounting seat mold

A mounting seat and mold technology, which is applied in the field of injection molds, can solve the problems affecting the appearance quality of injection molding workpieces, the difficulty in ensuring uniform mold clamping force, and easy generation of flashing around the product, so as to improve the appearance quality, high appearance quality, The effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

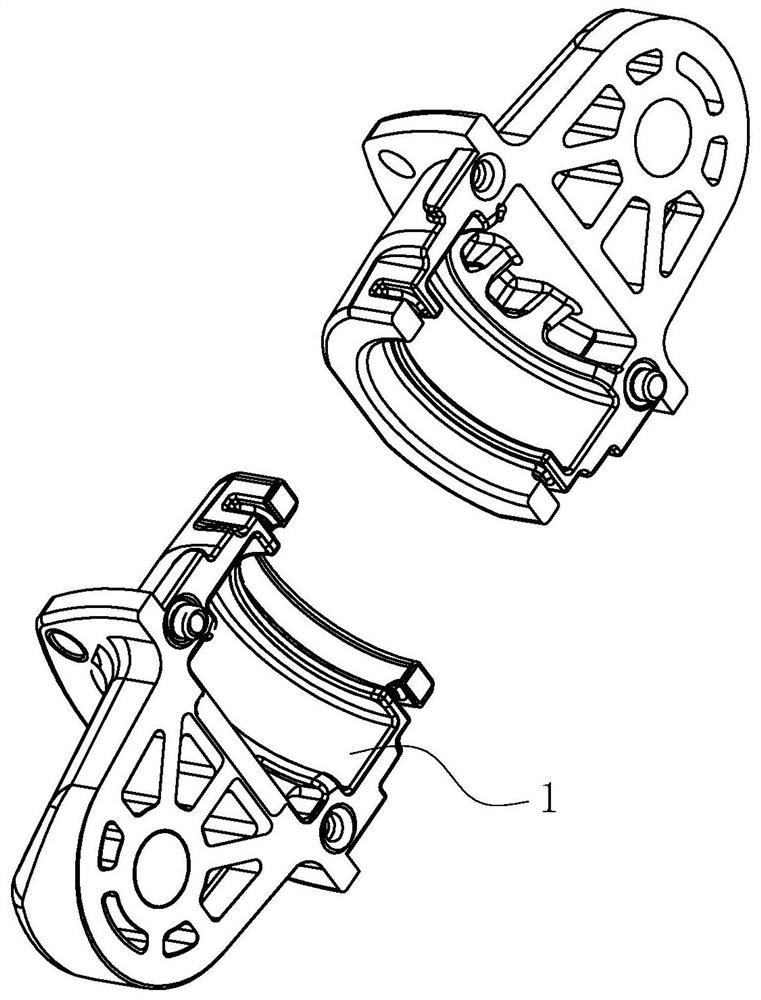

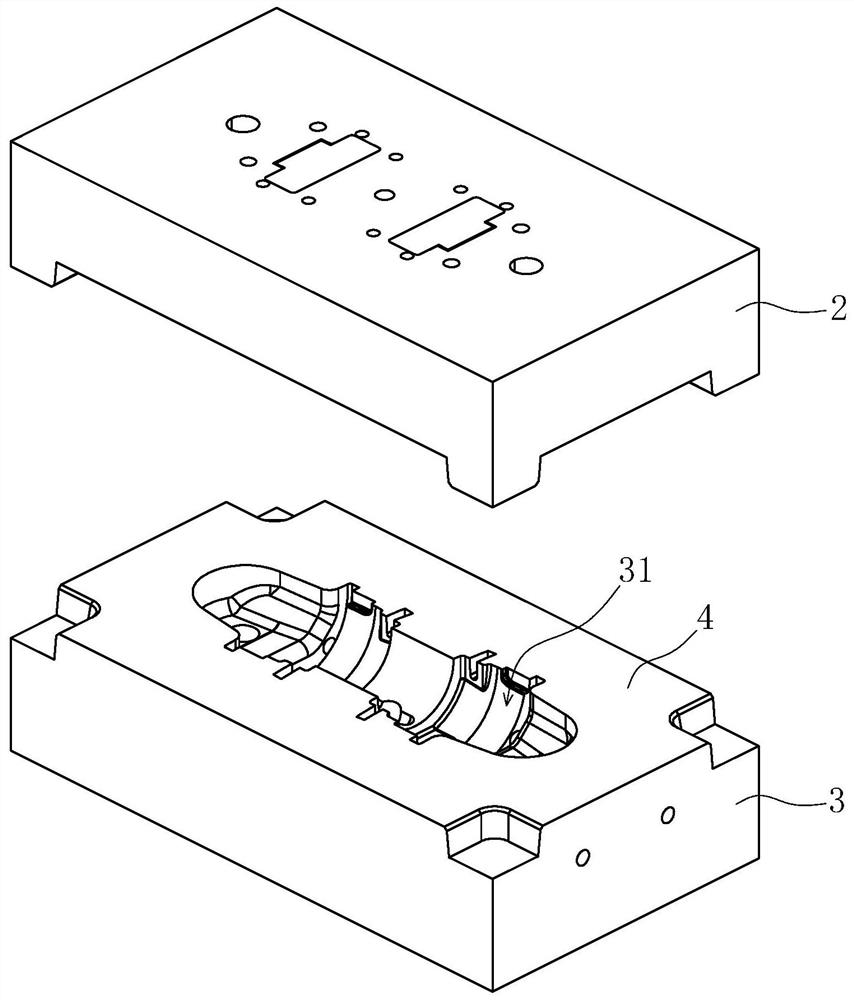

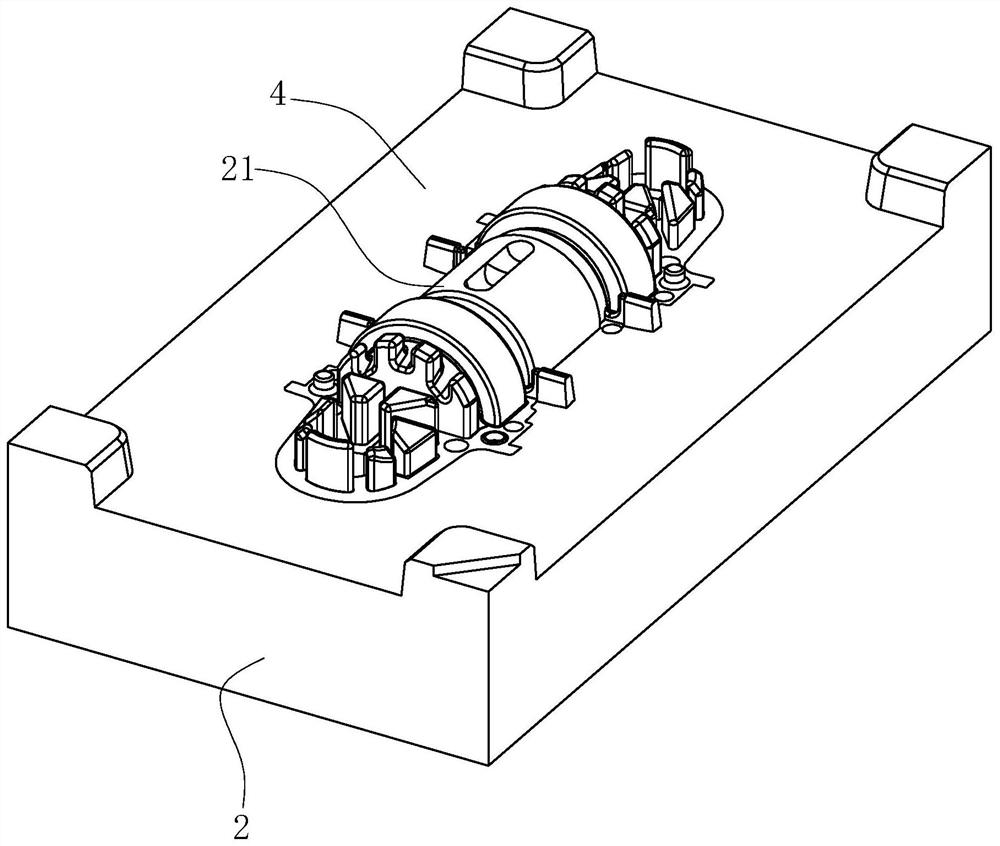

[0039] A motor mount mold, refer to Figure 4 and Figure 5 , which includes a punch 2 and a die 3. The male die 2 and the female die 3 are arranged oppositely, and the opposite end faces are provided with a forming surface 5 and a parting surface 4 which cooperate with each other. The molding surface 5 of the male mold 2 is provided with a protruding portion 21 , and the molding surface 5 of the female mold 3 is recessed to form a molding cavity 31 . After the male mold 2 and the concave mold 3 are closed, the protruding part 21 cooperates with the molding cavity 31 to form an injection molding, shape and motor mount housing 1 (refer to figure 1 ) the same "injection cavity". The mold of this embodiment can mold two plates of the motor mount housing 1 at one time.

[0040] refer to Figure 4 and Figure 5 , in order to increase the tightness of cooperation between the punch 2 and the die 3, the four corners of the punch 2 are provided with positioning blocks 22, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com