High-quality mulberry silk manufacturing technology

A production process and technology of mulberry silk, which is applied in silk reeling, silk fiber production, textiles and papermaking, etc., can solve problems such as unfavorable silk reeling, increase of production cost of silk factory, and increase of inner layer threading, so as to improve the clarity of raw silk and cleanliness, reduce equipment energy consumption, and improve the effect of contact steaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical content of the present invention will be further described in conjunction with the accompanying drawings.

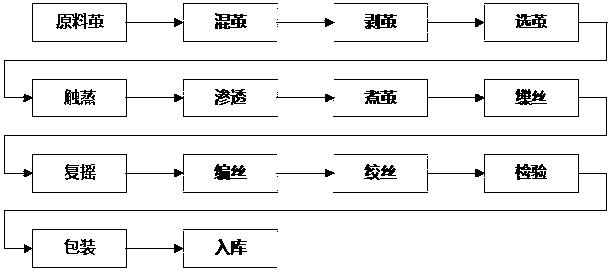

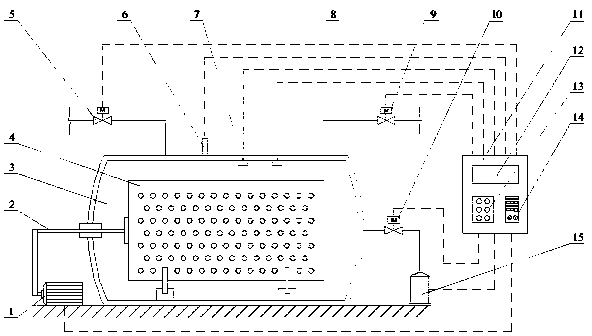

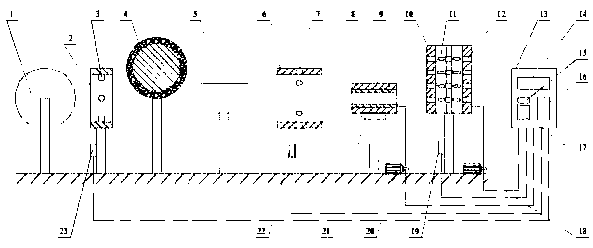

[0028] Such as figure 1 As shown, the production process of high-grade mulberry silk is implemented through the following specific steps: (1) Cocoon peeling and cocoon selection: After the cocoon mixing process, the raw cocoon is peeled off by an automatic cocoon peeling machine, the cocoon layer is peeled off, and the cocoon is removed. silkworm chrysalis, and then select high-quality cocoons; (2) Vacuum touch steaming: Put the selected silkworm cocoons into a vacuum touch steaming device for vacuum touch steaming; (3) Ultrasonic collaborative cocoon cooking: first vacuum touch steamed silkworm cocoons Vacuum osmosis water absorption treatment, add osmotic agent according to the ratio of 1kg osmotic agent to 100kg silkworm cocoons, infiltration water temperature 40℃, infiltration time 2min, vacuum degree 0.092Mpa, so that the water content of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com