Aqueous soft biomass anti-fouling paint and preparation method thereof

A technology of antifouling coatings and soft biomass, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of high VOC emissions, poisonous and harmful, unfavorable environmental protection, etc., and achieve energy saving , prevent adhesion, prolong the effect of antifouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Preparation of water-based soft biomass flexible cross-linked antifouling coating

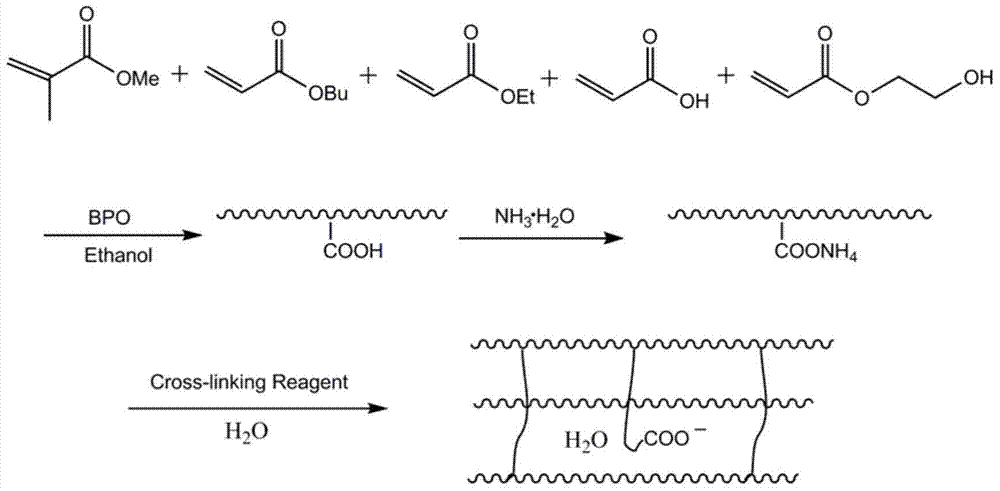

[0020] (1) Synthesis of water-based acrylic resin

[0021] In a four-necked flask equipped with a stirrer, reflux condenser, and constant pressure dropping funnel, 0.2g of benzoyl peroxide and 200g of ethanol were added, and the temperature was raised to 78°C. Then, 12g of acrylic acid and 46g of methyl were added to the mixture. A mixture of methyl acrylate, 71g ethyl acrylate, 63g butyl acrylate, 8g hydroxyethyl acrylate, 1.6g benzoyl peroxide, use a constant pressure dropping funnel to drip at a constant speed over 3 hours, add 0.2g Oxidize benzoyl, continue constant temperature reaction (78° C., the same below) for 3 hours, then cool to room temperature, add 25 g of ammonia water to adjust the pH to neutral, stir for 2 hours and complete the reaction to obtain an aqueous acrylic resin.

[0022] (2) Preparation of water-based soft bio-flexible cross-linked antifouling paint

[0023...

Embodiment 2

[0029] Example 2 Preparation of water-based soft bio-gel antifouling paint

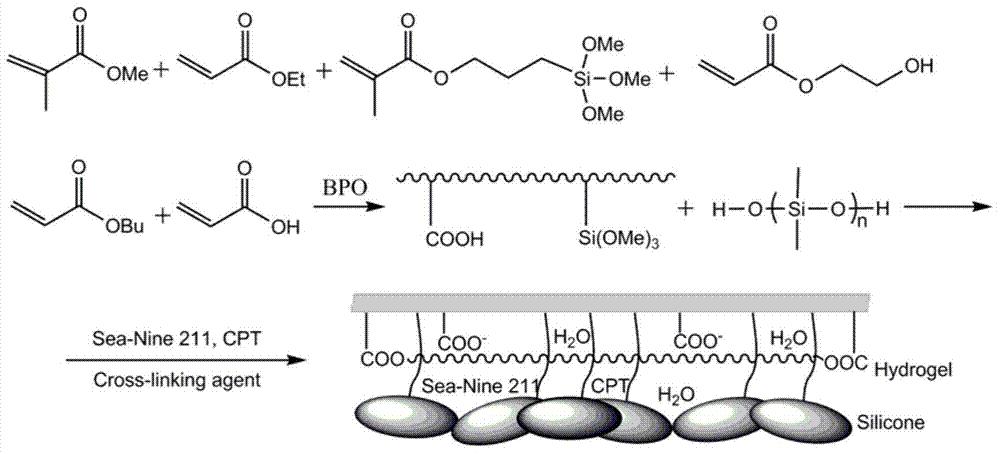

[0030] (1) Synthesis of modified waterborne acrylic resin

[0031] In a four-necked flask equipped with a stirrer, reflux condenser, and constant pressure dropping funnel, 0.2g of benzoyl peroxide and 200g of ethanol were added, and the temperature was raised to 78°C. Then, 12g of acrylic acid and 46g of methyl were added to the mixture. A mixture of methyl acrylate, 61g ethyl acrylate, 63g butyl acrylate, 10g γ-(methacryloxy) propyltrimethoxysilane, 8g hydroxyethyl acrylate, 1.6g benzoyl peroxide, use constant After 3 hours of constant rate dropping, add 0.2g of benzoyl peroxide in the pressure dropping funnel, continue constant temperature reaction for 3 hours, then cool to 60℃, add 20g of hydroxy silicone oil, react for 12h, cool to room temperature, add 15g of ammonia to adjust pH and the hydrophilicity of the resin, the reaction is completed after 2 hours of stirring, and the modified water-based acr...

Embodiment 3

[0039] Example 3: Preparation of water-based soft biological self-healing antifouling paint

[0040] (1) Synthesis of modified waterborne acrylic resin

[0041] In a four-necked flask equipped with a stirrer, reflux condenser, and constant pressure dropping funnel, 0.2g of benzoyl peroxide and 200g of ethanol were added, and the temperature was raised to 78°C. Then, 12g of acrylic acid and 46g of methyl were added to the mixture. A mixture of methyl acrylate, 61g ethyl acrylate, 63g butyl acrylate, 10g γ-(methacryloxy) propyltrimethoxysilane, 8g hydroxyethyl acrylate, 1.6g benzoyl peroxide, use constant After 3 hours of constant rate dropping, add 0.2g of benzoyl peroxide and continue constant temperature reaction for 3 hours, then cool to 60℃, add 20g of hydroxy silicone oil, react for 12h, cool to room temperature, add 15g of ammonia to adjust pH and the hydrophilicity of the resin, the reaction is completed after 2 hours of stirring, and the water-based acrylic resin is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com