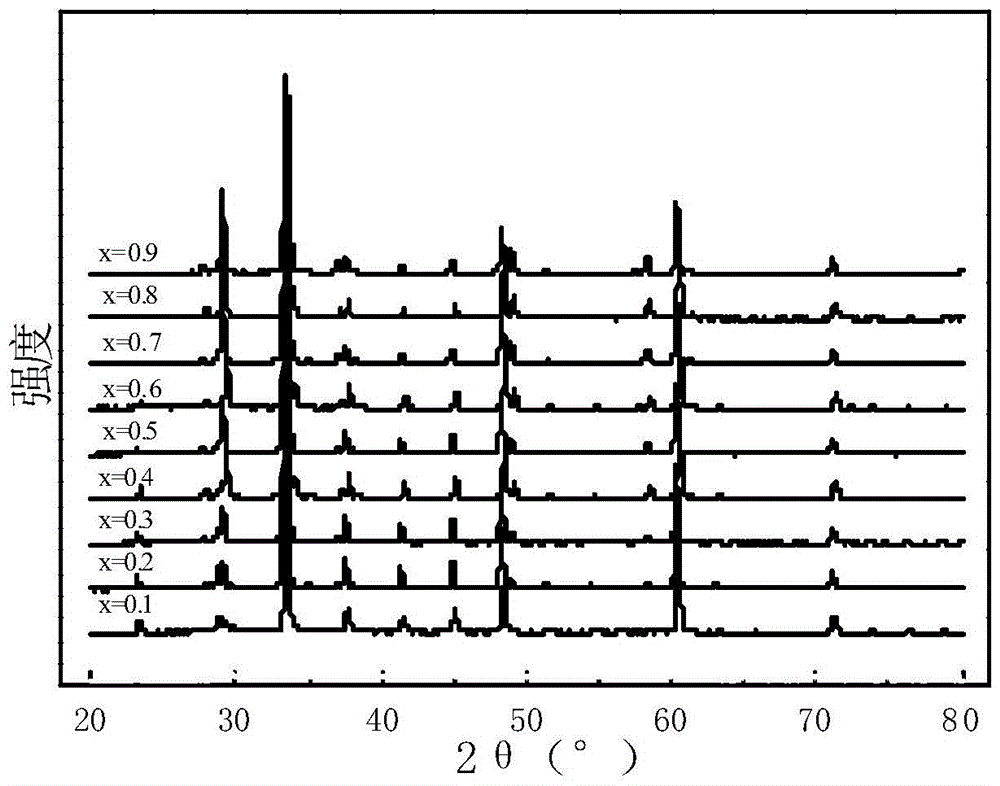

A kind of titanium iron niobate copper bismuth giant dielectric ceramic material and preparation method thereof

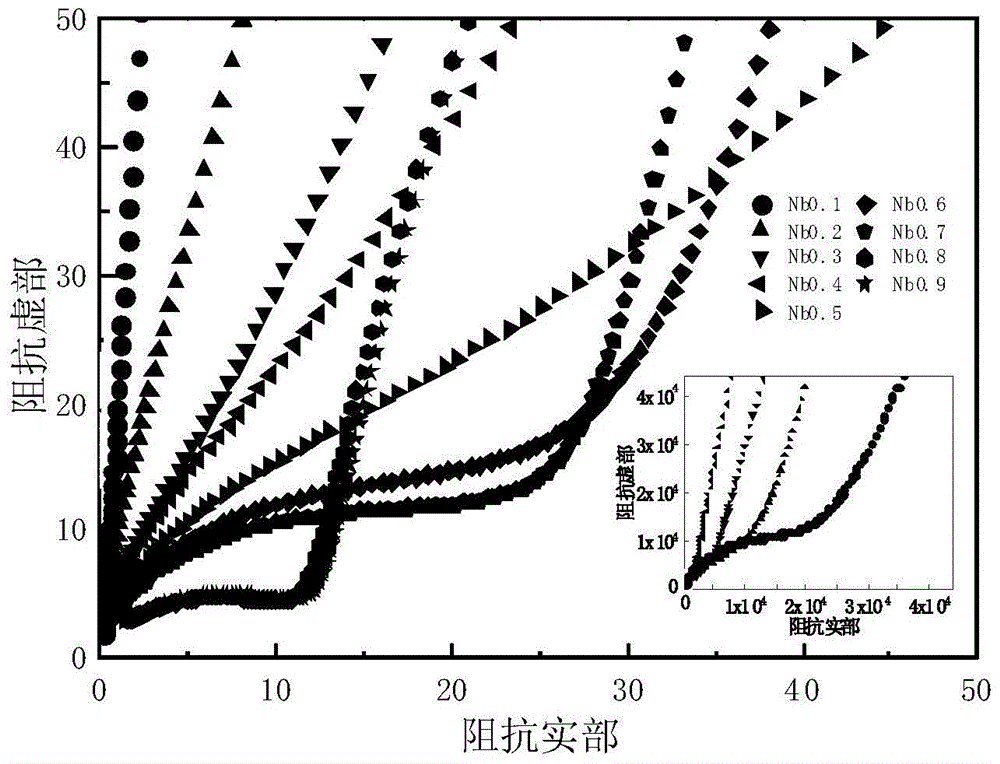

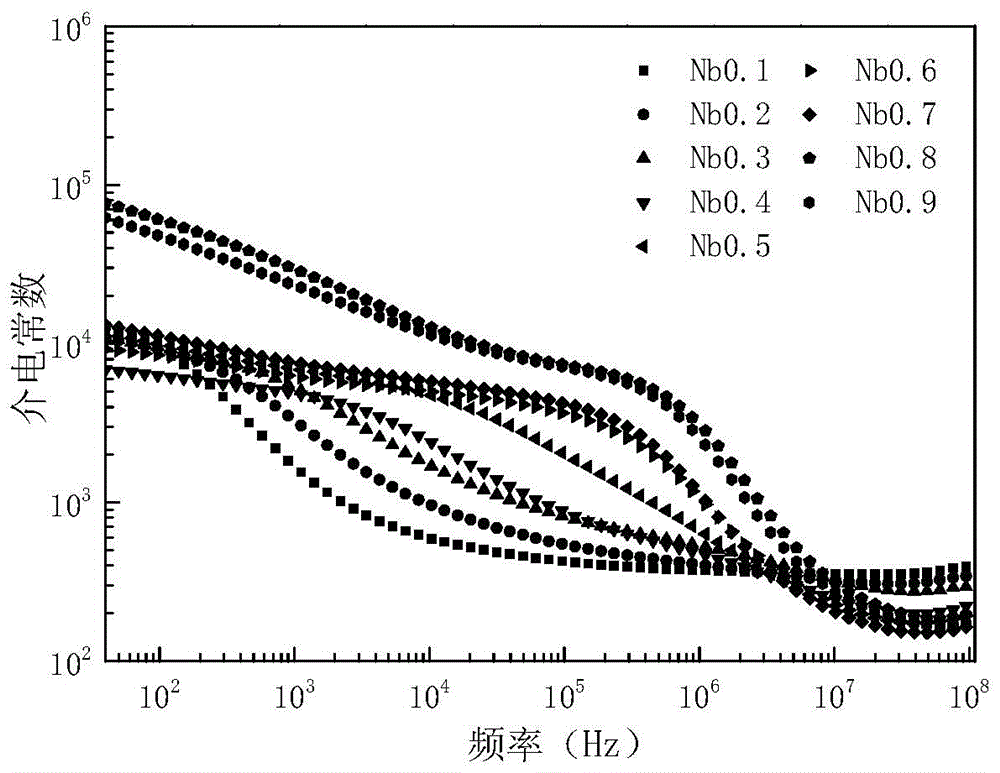

A ceramic material, copper niobate technology, applied in the direction of ceramics, inorganic insulators, etc., can solve the problems of low dielectric constant, increased grain resistance, and unobservable problems, achieve good temperature stability, and reduce grain resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of BiCu 3 Ti 3 Fe 0.7 Nb 0.3 o 12 The giant dielectric ceramic material represented, the raw materials used and the preparation method thereof are as follows:

[0032] 1. Ingredients

[0033] By BiCu 3 Ti 3 Fe 0.7 Nb 0.3 o 12 The stoichiometry of raw materials were weighed Bi 2 o 3 8.6899g, CuO8.9009g, TiO 2 8.8520g, Fe 2 o 3 2.0847g, Nb 2 o 5 1.4724g, mix evenly, put the raw material mixture into a nylon tank, add 20g of dispersant dehydrated alcohol, 66.7g of ball milling medium agate balls, the mass ratio of dehydrated alcohol and raw material mixture is 1:1.3, use ball mill 401 rpm Ball mill for 10 hours, separate the agate balls, place the raw material mixture in a drying oven at 80°C for 10 hours, grind with a mortar for 30 minutes, and pass through an 80-mesh sieve.

[0034] 2. Pre-burning

[0035] Put the raw material mixture passed through an 80-mesh sieve in an alumina crucible, and compact it with an agate rod so that the compact...

Embodiment 2

[0045] Preparation of BiCu 3 Ti 3 Fe 0.6 Nb 0.4 o 12 The giant dielectric ceramic material represented, the raw materials used and the preparation method thereof are as follows:

[0046] In the batching step 1 of embodiment 1, according to BiCu 3 Ti 3 Fe 0.6 Nb 0.4 o 12 The stoichiometry of raw materials were weighed Bi 2 o 3 8.6344g, CuO8.8440g, TiO 2 8.7954g, Fe 2 o 3 1.7755g, Nb 2 o 5 1.9507g, mix homogeneously, other steps of this step are identical with embodiment 1. The other steps are the same as in Example 1, to prepare titanium iron niobate copper bismuth giant dielectric ceramic material.

Embodiment 3

[0048] Preparation of BiCu 3 Ti 3 Fe 0.5 Nb 0.5 o 12 The giant dielectric ceramic material represented, the raw materials used and the preparation method thereof are as follows:

[0049] In the batching step 1 of embodiment 1, according to BiCu 3 Ti 3 Fe 0.5 Nb 0.5 o 12 The stoichiometry of raw materials were weighed Bi 2 o 3 8.5795g, CuO8.7879g, TiO 2 8.7395g, Fe 2 o 3 1.4702g, Nb 2 o 5 2.4229g, mix homogeneously, other steps of this step are identical with embodiment 1. The other steps are the same as in Example 1, to prepare titanium iron niobate copper bismuth giant dielectric ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com