Vacuum diffusion welding process for groove type cylindrical surface connecting piece

A vacuum diffusion welding furnace and welding process technology, applied in welding equipment, manufacturing tools, non-electric welding equipment and other directions, can solve the problems of pressure application, long welding heat cycle time, etc., achieve good quality, overcome radial inability to apply pressure, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Process T4 copper inner core and jacket:

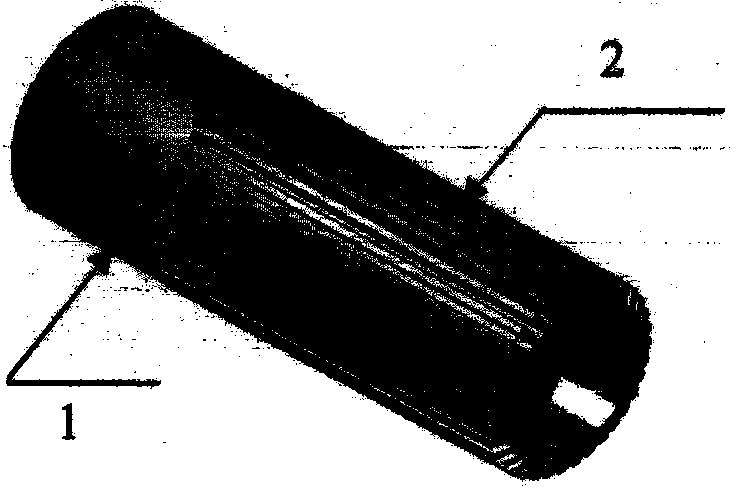

[0028] i. Process twenty ribs 2 with a width of 1 mm on a T4 copper inner core 1 with a diameter of Φ18 and a length of 40 mm.

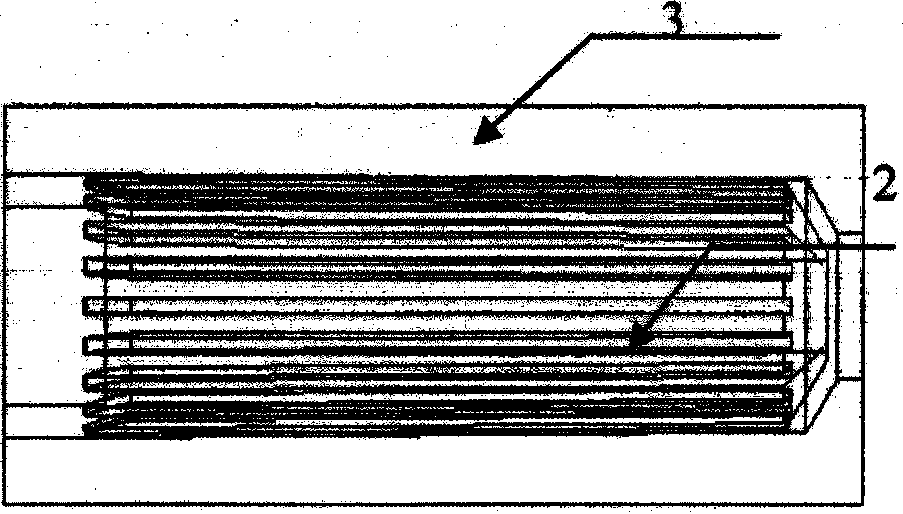

[0029] ii. The copper jacket 3 is processed into Φ22×Φ18 to ensure an interference fit between the two, and the surface roughness of the mating surface of the inner core 1 and the jacket 3 is Ra0.8.

[0030] 2) Make pressure applying tooling:

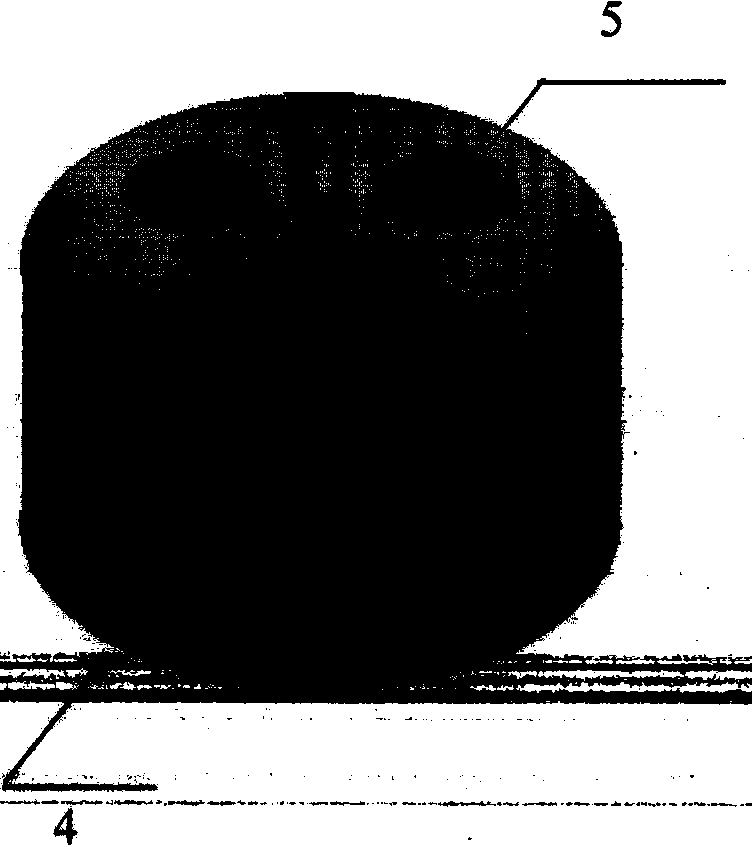

[0031] i. Use tungsten to make tooling 4.

[0032] ii. Process four Φ22×40mm (height) holes 5 on the tooling, and the matching gap between the holes 5 and the nozzle jacket 3 should be as small as possible.

[0033] 3) Inner core and jacket vacuum diffusion welding

[0034] Put the nozzle into tooling 4, put it into a vacuum diffusion welding furnace for welding, the welding temperature is 800°C, and the holding time is 120min.

[0035] 4) Post-weld processing

[0036] After the welding is completed, the outer surface of the vacuum diffusion welding noz...

Embodiment 2

[0038] 1) Process oxygen-free copper inner core and jacket

[0039] i. Process twenty-two ribs 2 with a width of 0.8 mm and a depth of 1 mm on an oxygen-free copper inner core 1 with a diameter of Φ22 and a length of 50 mm.

[0040] ii. Oxygen-free copper jacket 3 is processed into Φ25×Φ22, and the connection surface of inner core 1 and jacket 3 is processed at an angle of 1° to ensure interference fit between the two; the surface roughness of the mating surface of inner core and jacket is Ra1.6.

[0041] 2) Make pressure applying tooling

[0042] i. Use graphite to make tooling 4.

[0043] ii. Process five Φ25×50mm (height) holes 5 on the tooling, and the matching gap between the holes 5 and the nozzle jacket should be as small as possible.

[0044] 3) Vacuum diffusion welding of nozzle inner core and jacket

[0045] i. Before welding, the welding surface of the inner core and the outer jacket is plated with active agent.

[0046] ii. Put the nozzle into tooling 4, put it...

Embodiment 3

[0048] 1) Processing copper alloy inner core and jacket

[0049] i. Process twenty-two ribs 2 with a width of 0.8 mm and a depth of 1 mm on a copper alloy inner core 1 with a diameter of Φ18 and a length of 50 mm.

[0050] ii. Copper alloy jacket 3 is processed to Φ22×Φ18, and the connection surface processing angle of inner core 1 and jacket 3 is 0.6° to ensure interference fit between the two; the surface roughness of the mating surface of inner core and jacket is Ra1.6.

[0051] 2) Make pressure applying tooling

[0052] i. Use graphite to make tooling 4.

[0053] ii. Process five Φ22×50mm (height) holes 5 on the tooling, and the matching gap between the holes 5 and the nozzle jacket should be as small as possible.

[0054] 3) Vacuum diffusion welding of nozzle inner core and jacket

[0055] Put the nozzle into tooling 4, put it into a vacuum diffusion welding furnace for welding, the welding temperature is 850°C, and the holding time is 120min.

[0056] 4) Post-weld pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com