Carbon nanotube composite material as well as preparation method and application thereof

A carbon nanotube and composite material technology, applied in chemical instruments and methods, electrical components, circuits, etc., can solve the problems of decreased catalyst stability, decreased active area, loss of catalytic activity, etc., and achieves easy operation, high-efficiency catalytic activity, Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

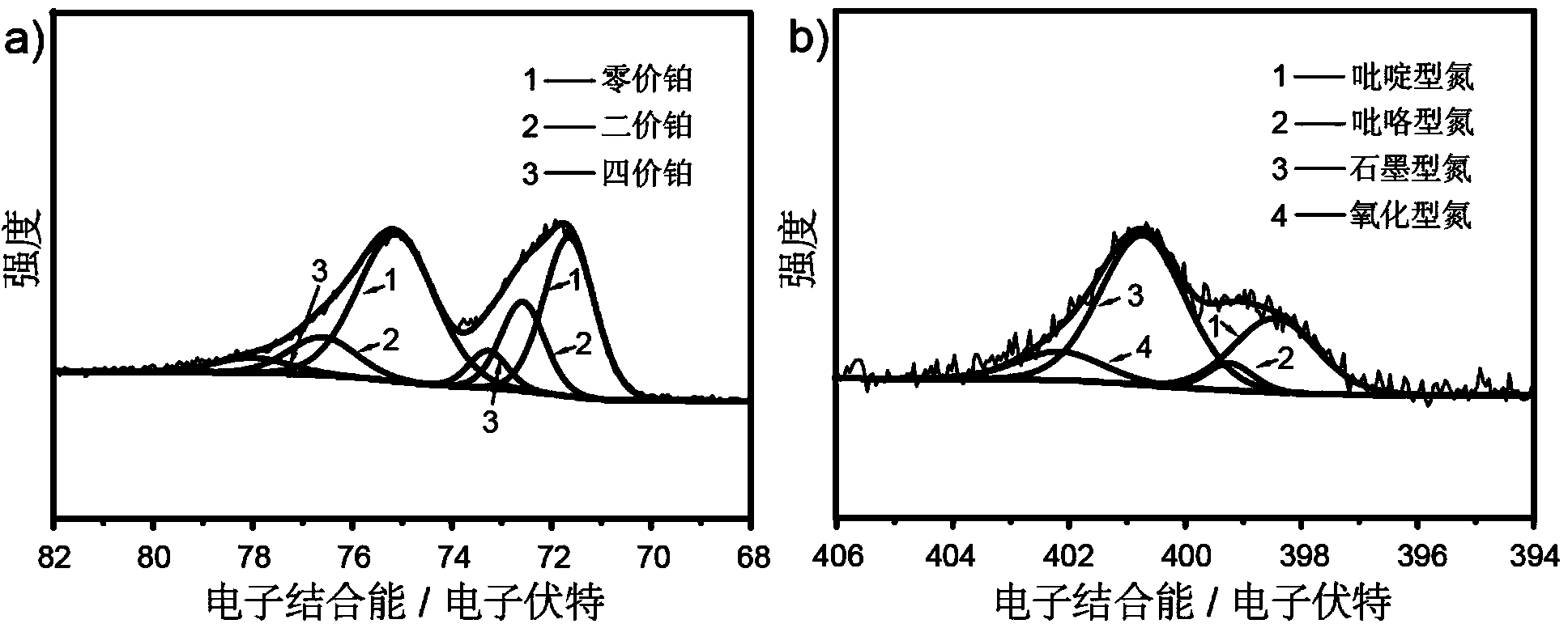

[0063] Weigh carbon nanotubes and aniline according to the mass ratio of carbon nanotubes: aniline of 1:0.8, and weigh dichlorotetraammine according to the molar ratio of aniline:dichlorotetraammine platinum:ammonium persulfate as 1:0.5:1.2 Platinum and ammonium persulfate, wherein the carbon nanotubes have a diameter of 20-60 nanometers and a length of 5-15 microns. First add carbon nanotubes and aniline to the hydrochloric acid solution with a pH value of 1, and ultrasonically and stir for 1 hour, then add dichlorotetraammine platinum to form a mixed solution, and stir at 5°C for 10 hours, then dissolve in pH The ammonium persulfate in the hydrochloric acid solution with a value of 1 is slowly added dropwise to the mixed solution, and the dropping time is controlled at 30 minutes. After the dropping is completed, continue to stir and react at 5°C for 20 hours; then evaporate the solution to dryness to obtain a solid The product is ground, washed and dried to obtain carbon na...

Embodiment 2

[0076] According to the same method as in Example 1, the temperature 900°C during the heat treatment is replaced by 1000°C, the thickness of the nitrogen-doped carbon layer of the obtained composite material is about 0.5 to 0.8 nanometers, and the particle size of the noble metal nanoparticles is between 3 and 3 nanometers. 11 nanometers, the atomic percentage of nitrogen atoms in the surface of the nitrogen-doped carbon layer is 2.93%.

Embodiment 3

[0078] According to the same method as in Example 1, carbon nanotubes and aniline were fed according to a mass ratio of 1:1, and the thickness of the nitrogen-doped carbon layer of the obtained composite material was about 0.6-1.1 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com