Method for rapidly guaranteeing quality of dried honeysuckle flower

A honeysuckle and drying technology, which is applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of uneven heating, complicated operation, high drying cost, etc., and increase the content of chlorophyll and chlorogenic acid. , the effect of inhibiting the enzymatic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

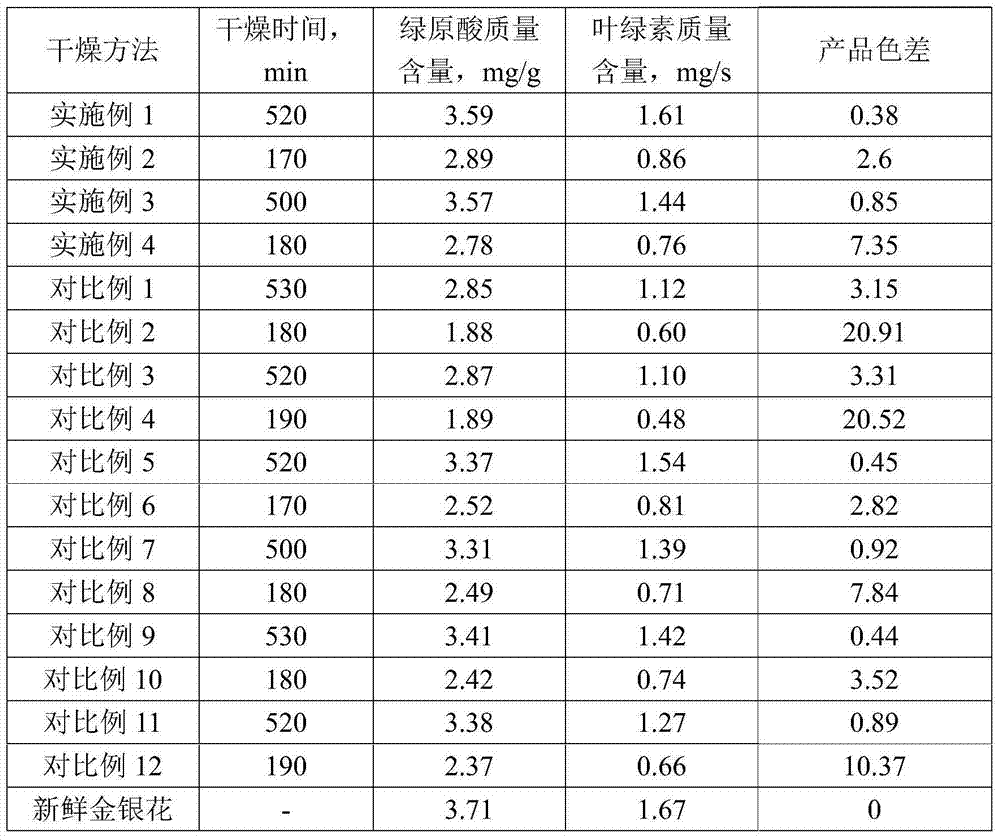

Examples

Embodiment 1

[0021] In the present embodiment, the method for fast and quality-preserving drying honeysuckle comprises the following steps:

[0022] (1) Select 100g of mature honeysuckle, spread it on the material tray, and the thickness of the material layer is 4mm (3-4mm is acceptable);

[0023] (2) Nitrogen is charged into the controlled atmosphere dryer, and the drying temperature is adjusted to be 40°C, the wind speed is 0.5m / s, and the oxygen concentration is 5%;

[0024] (3) Place the material tray containing honeysuckle in the drying chamber of the controlled atmosphere dryer, use an atomizer to atomize the ethanol solution into steam, and spray ethanol vapor on the surface of the material at the initial stage of drying. The pump equipped with the atomizer is The atomization pressure of the peristaltic pump is 100kN / m 2, the diameter of the nozzle is 0.5m, using 4 nozzles, the flow rate of ethanol vapor generated is 50mL / min, the volume fraction of ethanol vapor in the drying medi...

Embodiment 2

[0027] In the present embodiment, the method for fast and quality-preserving drying honeysuckle comprises the following steps:

[0028] (1) Select 100g of mature honeysuckle, spread it in a material tray, and the thickness of the material layer is 4mm;

[0029] (2) Nitrogen is charged into the controlled atmosphere dryer, and the drying temperature is adjusted to be 70°C, the wind speed is 4m / s, and the oxygen concentration is 5%;

[0030] (3) Place the material tray containing honeysuckle in the drying chamber of the controlled atmosphere dryer, use an atomizer to atomize the ethanol solution into steam, and spray ethanol vapor on the surface of the material at the initial stage of drying. The atomizer is equipped with a pump of The atomization pressure of the peristaltic pump is 100kN / m 2 , the diameter of the nozzle is 0.5m, using 4 nozzles, the flow rate of ethanol vapor generated is 50mL / min, the volume fraction of ethanol vapor in the drying medium is 5%, the spraying t...

Embodiment 3

[0033] In the present embodiment, the method for fast and quality-preserving drying honeysuckle comprises the following steps:

[0034] (1) Select 100g of mature honeysuckle, spread it in a material tray, and the thickness of the material layer is 4mm;

[0035] (2) Nitrogen is charged into the controlled atmosphere dryer, and the drying temperature is adjusted to be 40°C, the wind speed is 4m / s, and the oxygen concentration is 10%;

[0036] (3) Place the material tray containing honeysuckle in the drying chamber of the controlled atmosphere dryer, use an atomizer to atomize the ethanol solution into steam, and spray ethanol vapor on the surface of the material at the initial stage of drying. The atomizer is equipped with a pump of The atomization pressure of the peristaltic pump is 60kN / m 2 , the diameter of the nozzle is 0.5m, using 2 nozzles, the flow rate of ethanol vapor generated is 10mL / min, the volume fraction of ethanol vapor in the drying medium is 1%, the spraying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com