Method for connecting two battery poles, which consist of unidentical materials, of two battery cells, and battery unit

A technology for battery cells and battery cells, applied in electrical components, battery pack parts, high-frequency current welding equipment, etc., can solve the problems of high additional cost, difficult to control processing technology, and difficult to manufacture welding connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

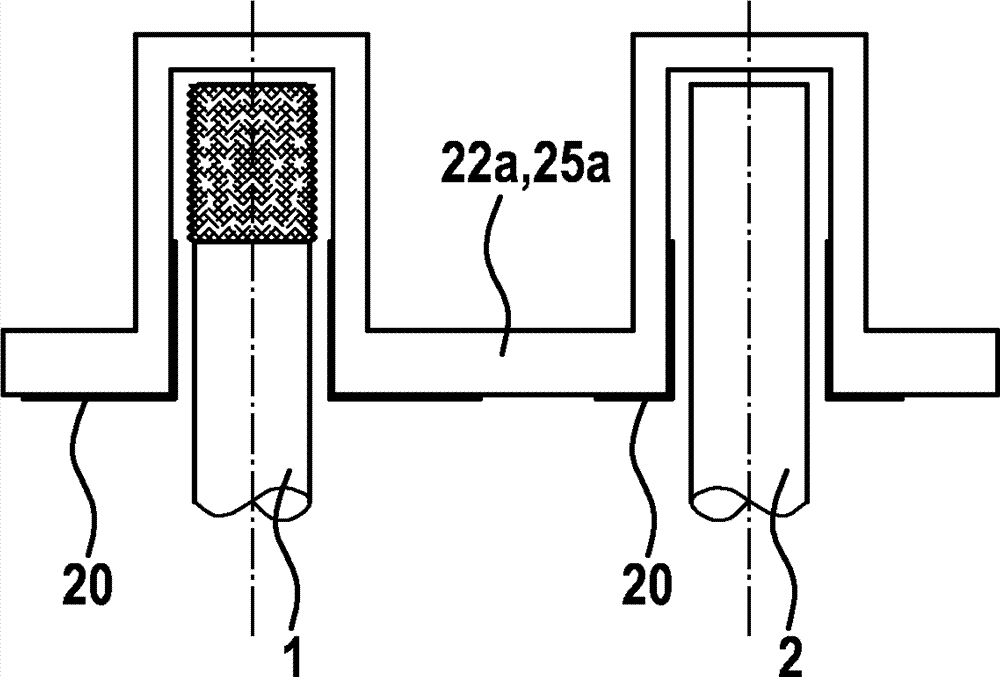

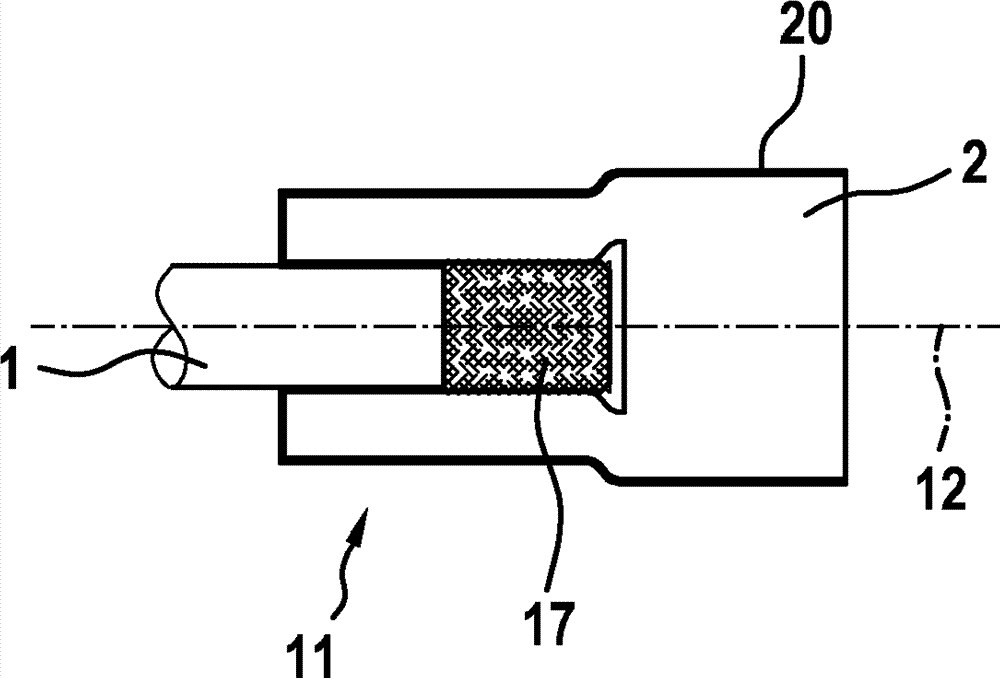

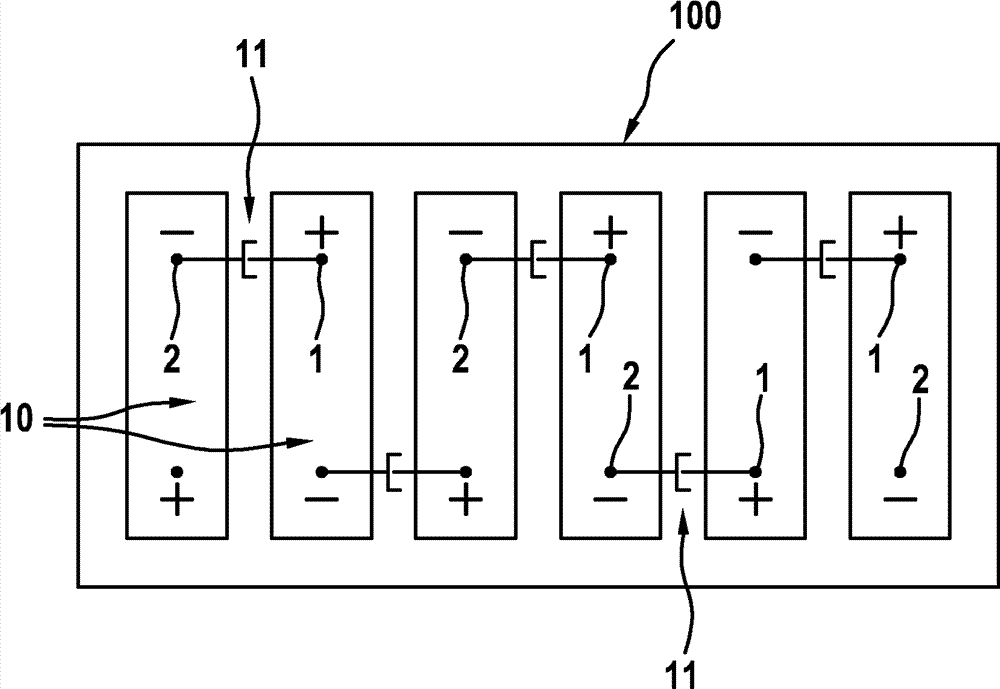

[0018] exist figure 1 A battery cell 100 is shown in a greatly simplified manner, which consists of a large number of battery cells 10 connected to each other. exist figure 1 In the drawings, only six battery cells 10 are shown connected to each other for the sake of simplicity, however, in practice, such a battery cell 100 may also consist of more than six battery cells 10 . Such a battery cell 100 is preferably, but not limited to, use in motor vehicles, in particular as part of a hybrid drive. Furthermore, the battery cells 10 are in particular lithium-ion battery cells 10 with a positive electrode 1 and a negative electrode 2 in each case. In the embodiment shown, all six battery cells 10 are electrically connected in series such that the individual cell voltages of the battery cells add up. It is of course also within the scope of the invention that the battery cells 10 are electrically connected in parallel at least partially.

[0019] A feature of the battery cell 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com