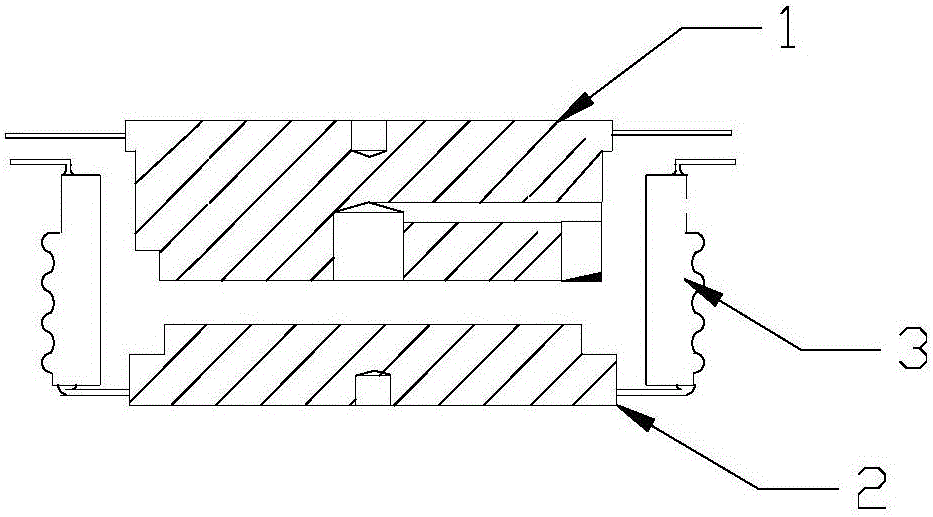

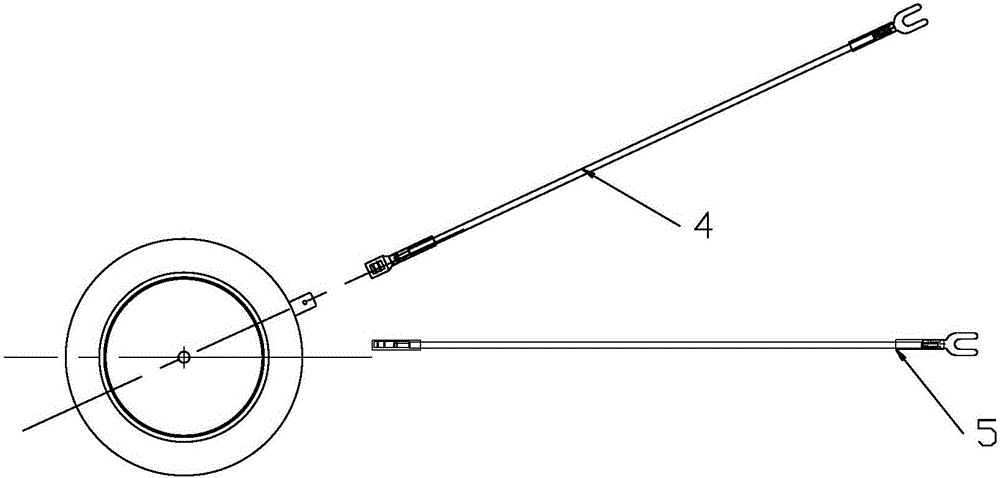

Manufacturing method of over-temperature self-protection thyristor for electric heating equipment

A manufacturing method and electric heating technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] [Example 1] A batch of over-temperature self-protection thyristors were produced by adopting the method of the present invention

[0080] The specific production process is as follows:

[0081] Put the monocrystalline silicon wafer in detergent: deionized water = 30ml: 500ml of cleaning solution for ultrasonication for 1 hour, rinse with hot deionized water for 30 times, and rinse with cold deionized water for 30 times; place the silicon wafer in four On the fluorine rack, use pure hydrofluoric acid to sonicate for 10 minutes, rinse with normal temperature deionized water for 30 times, and then rinse with hot deionized water for 30 times; then place the silicon wafer in a sodium hydroxide solution with a mass concentration of 5%, Boil in a constant temperature water bath at 85°C for 1 minute, rinse with cold deionized water for 30 times, and hot deionized water for 30 times, and test that the resistivity of the effluent water after cleaning reaches 10MΩ or more, then pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com