Method for preparing wheat bran xylooligosaccharide by superpressure-enzyme combination process

A technology of wheat bran and xylo-oligosaccharide, which is applied in the directions of food preparation, food science, application, etc., can solve the problems of not being fully and reasonably utilized, and achieves rapid and thorough enzymatic hydrolysis reaction, improved economic benefits, and a wide range of sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Selection of optimal compound enzyme ratio

[0031] Take 10g of wheat bran, add 150mL of distilled water, and add amylase (1.5%-2.5%), glucoamylase (1.0-2.0%), papain (2.5%-3.5%) at the same time, at 65°C and pH 5.5 After hydrolysis for 180 minutes, the residual amounts of starch and protein were measured to be 0.2% and 4.5%, respectively, and the optimal compound enzyme ratio was obtained to be 2:1:3.

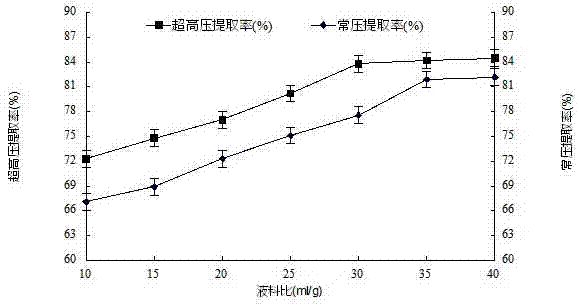

[0032] (2) Selection of optimal material-to-liquid ratio for ultra-high pressure combined with enzyme method

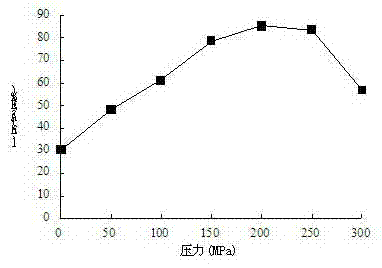

[0033] Because within a certain range, the greater the substrate concentration, the more the amount of wheat bran reacted with the enzyme per unit time, that is, the faster the enzymatic reaction rate. When the amount of wheat bran increases to a certain extent, the rate reaches the maximum and the extraction rate is the highest. as attached figure 1 It is shown that under the condition of 200 MPa, when the solid-liquid ratio is about 1:30 (g / mL), the ext...

Embodiment 2

[0046] (1) Grinding through a 40-mesh sieve and drying to constant weight;

[0047] (2) Take an appropriate amount of wheat bran and add distilled water, wherein the weight ratio of wheat bran to water is 1:25. Add 2% amylase, 1% glucoamylase, and 3% papain to enzymatically hydrolyze wheat bran, and hydrolyze for 180min at 65°C and pH 5.5;

[0048] (3) After suction filtration with filter paper, the sediment was washed with distilled water for 3 times and then dried to constant weight to obtain wheat bran dietary fiber containing 0.21% starch and 4.5% protein;

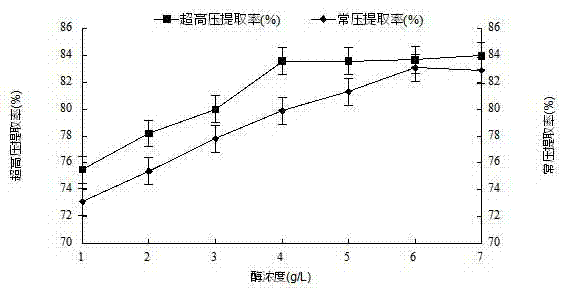

[0049] (4) Extract xylooligosaccharides from the residue by ultra-high pressure combined with enzyme method: take the dried wheat bran dietary fiber in step (3), add distilled water, and control the ratio of solid to liquid at 1:30 (g / mL), according to Add xylanase at a ratio of 4.0g / L, react immediately under 250MPa pressure for 25min, hold pressure at 40°C, and the extraction rate is 84.67%;

[0050] (5) Deenzyme t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com