Biological crude oil prepared by co-liquefying algae and crude glycerine and method for preparing biological crude oil by co-liquefying algae and crude glycerine

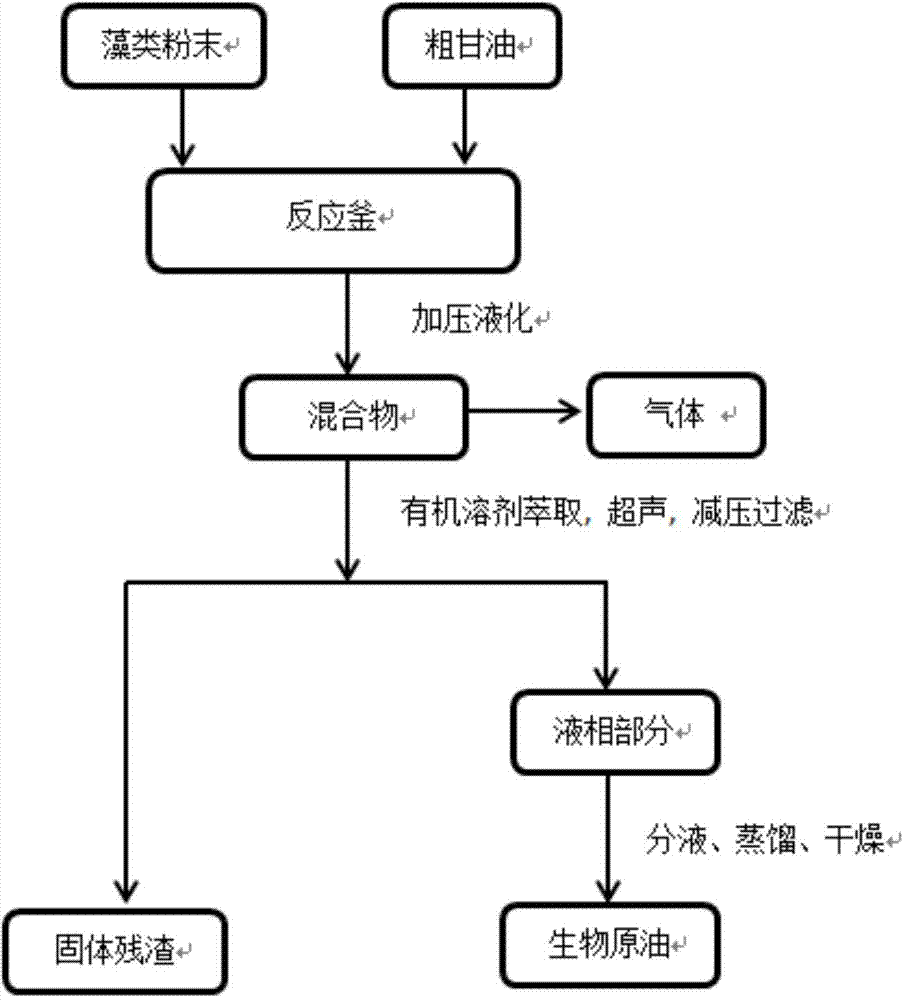

A technology for biological crude oil and crude glycerol, which is applied in the preparation of biological raw materials, liquid hydrocarbon mixtures, and petroleum industry, etc., can solve the problems of ineffective utilization of crude glycerol, and achieve the effects of high energy utilization efficiency, fast conversion rate and complete reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing biological crude oil by co-liquefaction of algae and crude glycerin, comprising the steps of:

[0033] (1) Add 10 g of crude glycerin to the reaction kettle, seal the reaction kettle, and adjust the initial pressure in the reaction kettle to 8 MPa with nitrogen gas, and the stirrer speed is 800 rpm. If there is no change in pressure after 10 minutes, the air tightness is considered to be good.

[0034] (2) Heat the reactor to 240° C. at a heating rate of 5° C. / min and keep for 180 minutes, then stop heating and wait for the reactor to cool down to room temperature.

[0035] (3) After the reaction kettle is cooled to room temperature, first collect the gas, then open the reaction kettle, collect the product with a glass, wash the kettle body with 150ml of acetone, and then pour it into a beaker. Place the beaker in a sonicator for 30 min.

[0036] (4) The product after ultrasonic extraction is filtered under reduced pressure. The filtered liquid p...

Embodiment 2

[0039] A method for preparing biological crude oil by co-liquefaction of algae and crude glycerin, comprising the steps of:

[0040] (1) Add 5g of Enteromorpha powder and 10g of crude glycerin to the reactor, seal the reactor, adjust the initial pressure in the reactor to 6MPa with nitrogen gas, the stirrer speed is 600rpm, and if there is no change in the pressure after 10 minutes, it is considered gas. Good tightness.

[0041] (2) Heat the reactor to 320° C. at a heating rate of 12° C. / min and keep for 120 minutes, then stop heating, and wait for the reactor to cool down to room temperature.

[0042] (3) After the reaction kettle is cooled to room temperature, first let off the gas, then open the reaction kettle, collect the product with a glass, wash the kettle body with 150ml of ethyl acetate, and then pour it into a beaker. Place the beaker in a sonicator for 30 min.

[0043](4) The product after ultrasonic extraction is filtered under reduced pressure. The filtered liq...

Embodiment 3

[0046] A method for preparing biological crude oil by co-liquefaction of algae and crude glycerin, comprising the steps of:

[0047] (1) Add 5g of chlorella powder and 20g of crude glycerin into the reaction kettle, seal the reaction kettle, and adjust the initial pressure in the reaction kettle to 1MPa with nitrogen gas, the stirrer speed is 300rpm, and the pressure does not change after 10 minutes, then it is considered Good air tightness.

[0048] (2) Heat the reactor to 400° C. at a heating rate of 15° C. / min and keep for 60 minutes, then stop heating and wait for the reactor to cool down to room temperature.

[0049] (3) After the reaction kettle is cooled to room temperature, first let off the gas, then open the reaction kettle, collect the product with a glass, wash the kettle body with 150ml of toluene, and then pour it into a beaker. Place the beaker in a sonicator for 30 min.

[0050] (4) The product after ultrasonic extraction is filtered under reduced pressure. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com