High-performance thermoplastic polyester composite material and preparation method thereof

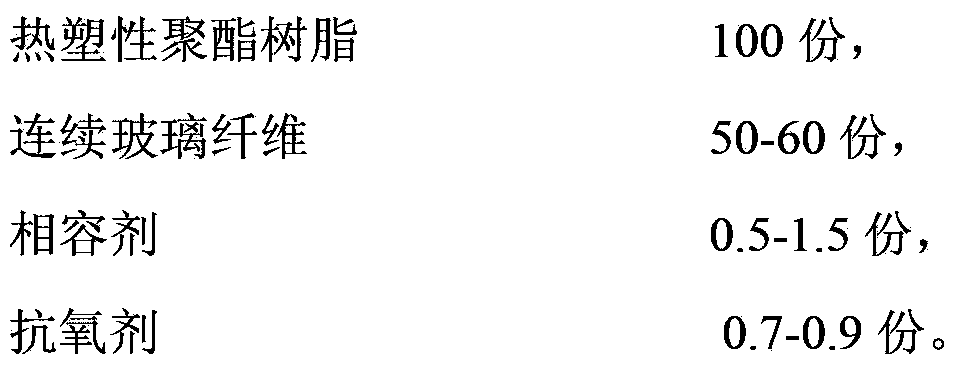

A thermoplastic polyester and composite material technology, which is applied in the field of composite materials, can solve the problems of glass fiber addition shearing and abrasion, and poor interface bonding between thermoplastic polyester resin and glass fiber, and achieves the effect of heat resistance and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

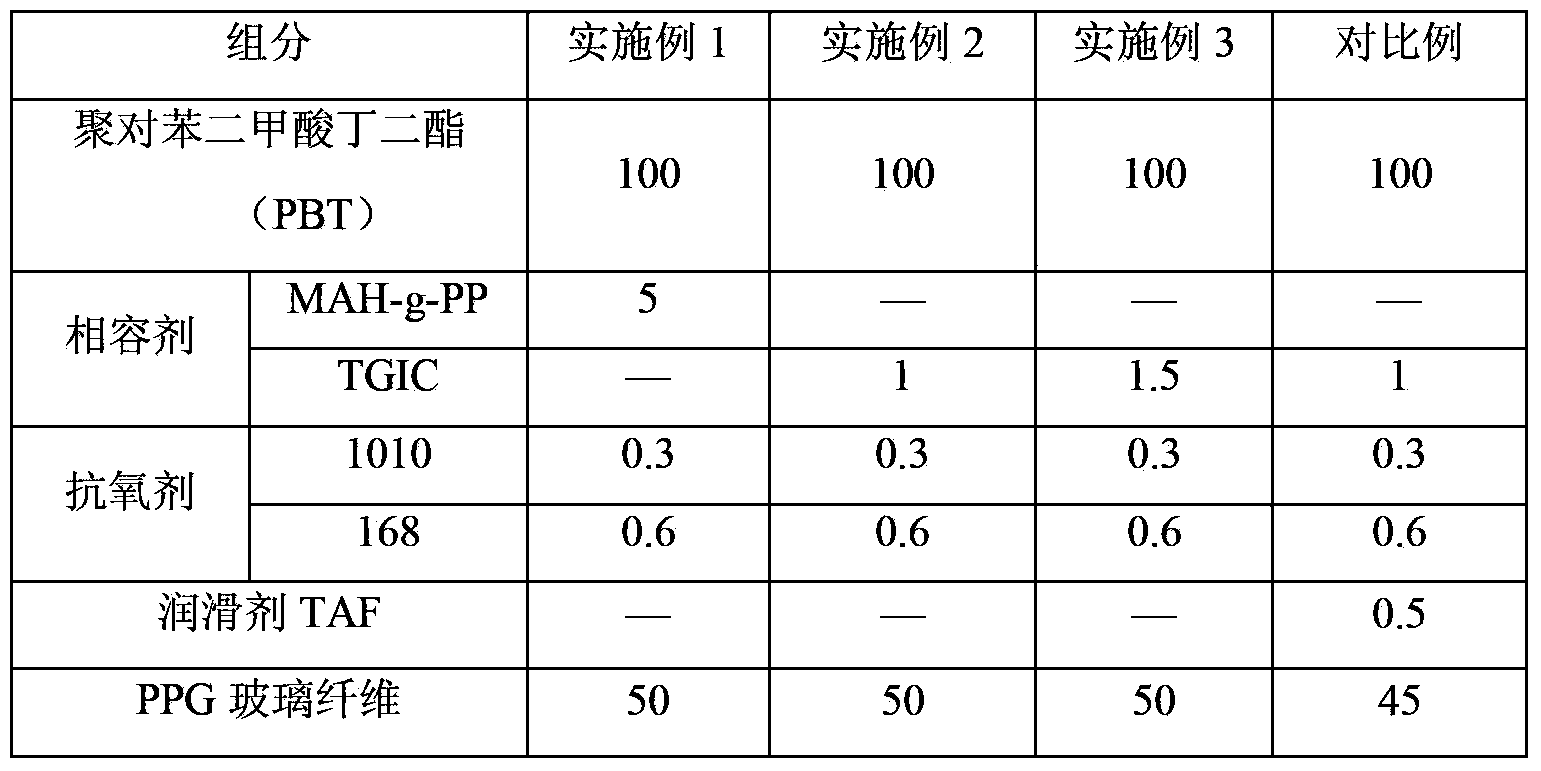

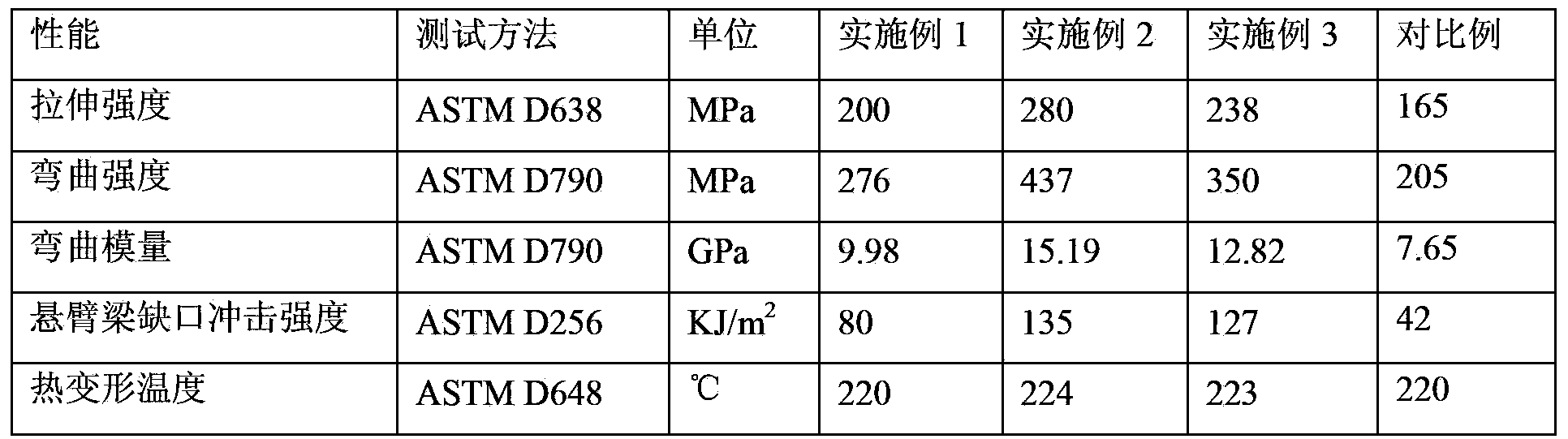

[0024] (1) Weigh each component according to the content given in Table 1;

[0025] (2) Dry the PBT resin at 120-140°C for more than 4 hours until the moisture content is ≤0.02%;

[0026] (3) Mix the dried PBT with compatibilizer MAH-g-PP, antioxidant 1010 and antioxidant 168 in a high-speed mixer according to the ratio of Example 1, and send it into a single-screw extruder In the process, melt and extrude in the temperature range of 210°C-268°C, and evenly coat the film at the rotatable double extrusion die to obtain a uniform thermoplastic polyester film;

[0027] (4) Roll the obtained uniform thermoplastic polyester film on both sides of the continuously dispersed glass fiber after infrared heating to prepare a high-performance PBT prepreg tape, and then heat-press it into a composite sheet. The pressing process of the sheet: 235°C, 1MPa, hot pressing for 30 minutes, cold pressing for 30 minutes to obtain thermoplastic polyester composite materials.

Embodiment 2

[0029] (1) Weigh each component according to the content given in Table 1;

[0030] (2) Dry the PBT resin at 120-140°C for more than 4 hours until the moisture content is ≤0.02%;

[0031] (3) Mix the dried PBT with compatibilizer TGIC, antioxidant 1010 and antioxidant 168 in a high-speed mixer according to the ratio of Example 2, and then send them into a single-screw extruder. Melt extrusion within the temperature range of ℃-268℃, and evenly coat the film at the rotatable double extrusion die to obtain a uniform thermoplastic polyester film;

[0032] (4) Roll the obtained uniform thermoplastic polyester film on both sides of the continuously dispersed glass fiber after infrared heating to prepare a high-performance PBT prepreg tape, and then heat-press it into a composite sheet. The pressing process of the sheet: 235°C, 1MPa, hot pressing for 30 minutes, cold pressing for 30 minutes to obtain thermoplastic polyester composite materials.

Embodiment 3

[0034] (1) Weigh each component according to the content given in Table 1;

[0035] (2) Dry the PBT resin at 120-140°C for more than 4 hours until the moisture content is ≤0.02%;

[0036] (3) Mix the dried PBT with the compatibilizer TGIC, antioxidant 1010 and antioxidant 168 in a high-speed mixer according to the ratio of Example 3, and then send them into a single-screw extruder. Melt extrusion within the temperature range of ℃-268℃, and evenly coat the film at the rotatable double extrusion die to obtain a uniform thermoplastic polyester film;

[0037] (4) Roll the obtained uniform thermoplastic polyester film on both sides of the continuously dispersed glass fiber after infrared heating to prepare a high-performance PBT prepreg tape, and then heat-press it into a composite sheet. The pressing process of the sheet: 235°C, 1MPa, hot pressing for 30 minutes, cold pressing for 30 minutes to obtain thermoplastic polyester composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com