Method for measuring heat conductivity of active heat-protection type calorimeter by virtue of quasi-steady-state method and correction method of active heat-protection type calorimeter

A technology of measuring device and calorimeter, which is applied in the direction of material thermal development, etc., can solve the problems of low density, good promotion, and inability to popularize and apply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

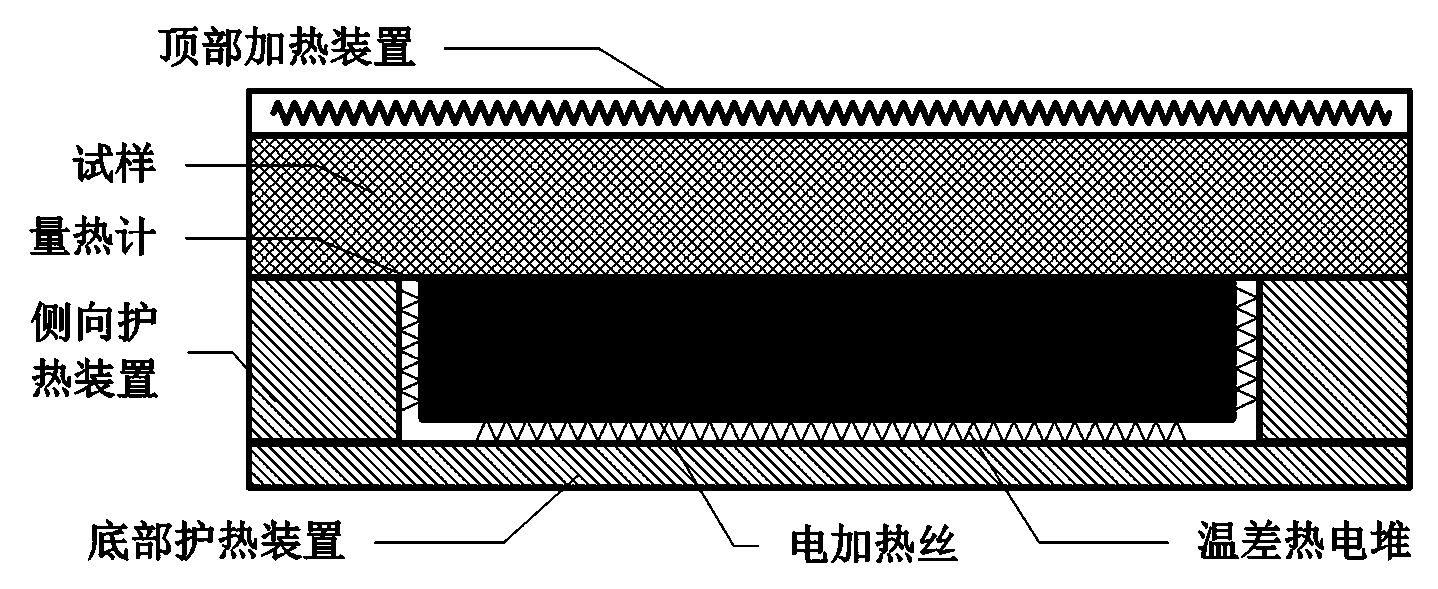

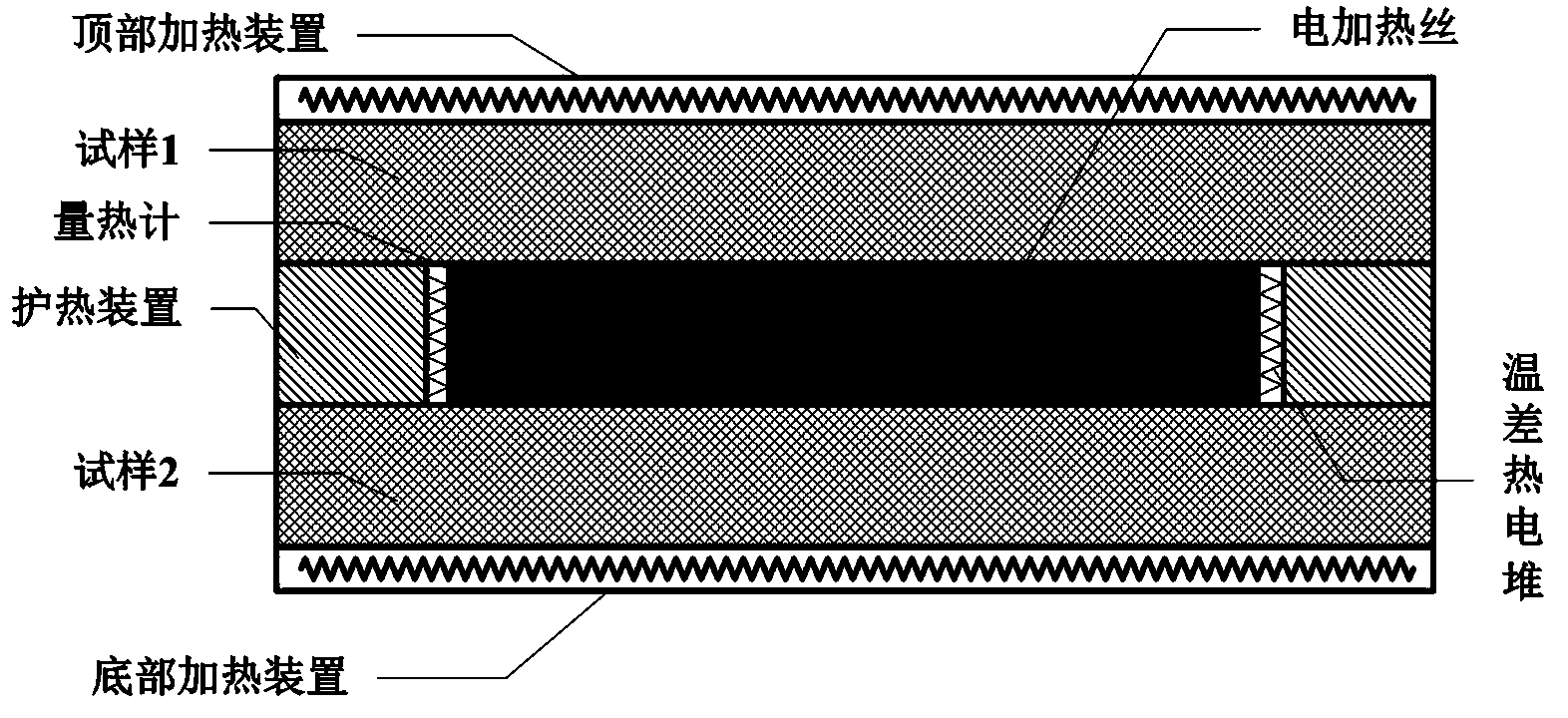

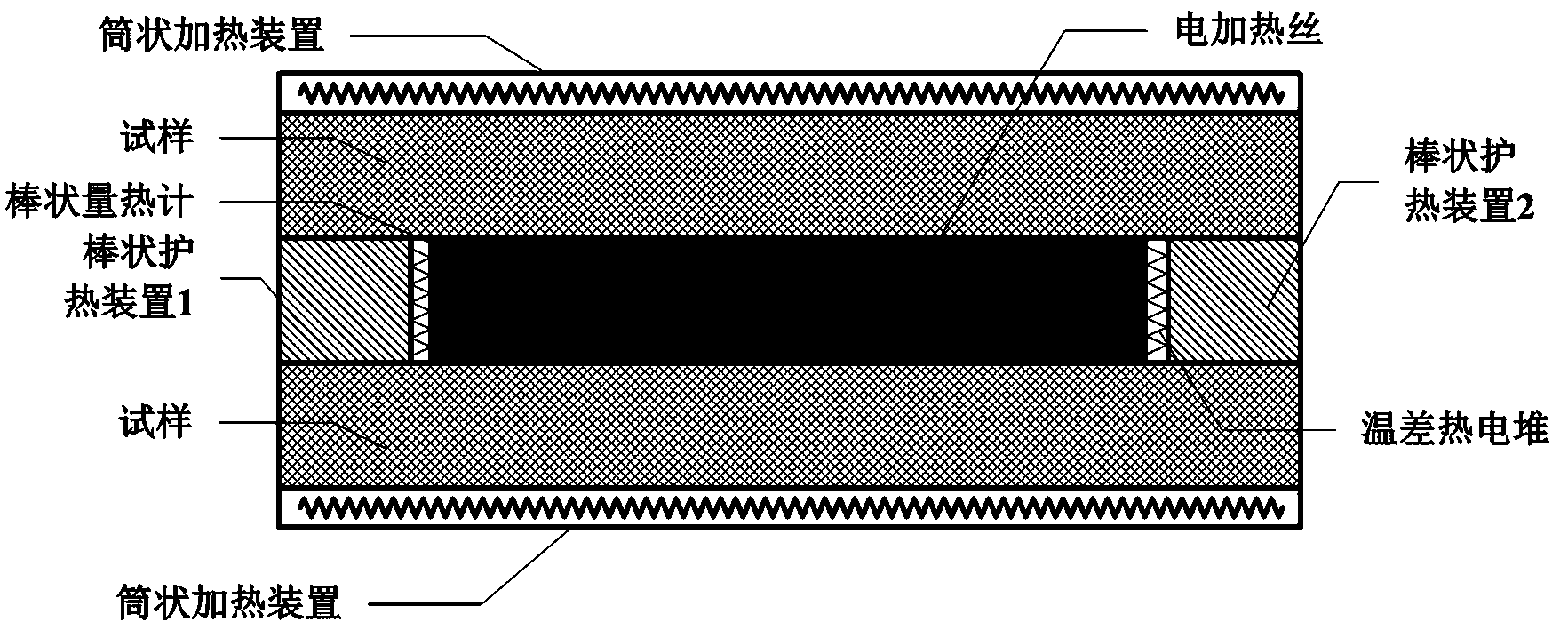

[0070] for figure 1 , figure 2 and image 3 In the quasi-steady-state thermal conductivity measuring device of the active-protected heat calorimeter shown, the test sample is not installed or all the test samples are removed, and electric heating wires are embedded in the corresponding calorimeters.

[0071] for figure 1 and figure 2 In the measurement device shown, the top heating device and the bottom heating device are installed close to the calorimeter but not in contact with the calorimeter, and the gap width between the calorimeter and the calorimeter is kept within 1mm. A thermopile is installed and arranged in these gaps to detect the temperature difference between the calorimeter and the top heating device and the bottom heating device.

[0072] for image 3 The measuring device shown requires a separate small-diameter cylindrical heating device, and this is placed on the rod calorimeter and the rod heat protection device so that the inner circular surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com