Preparation method of highly flavored edible oil

A technology for edible oil and strong aroma, which is applied in the direction of fat oil/fat refining, fat oil/fat production, and fat production, etc., can solve the problems of inability to filter edible oil, dark color of edible oil, unfavorable for environmental protection, etc., to speed up the baking speed , Low processing temperature, retention of nutrients and the effect of physical appearance and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a kind of preparation method of Luzhou flavor edible oil, comprises the following steps:

[0028] 1) softening the raw materials for oil extraction to obtain softened materials;

[0029] 2) Microwave drying the softened material in step 1) to obtain a dried material;

[0030] In terms of weight percentage, the moisture content of the dry material is 5% to 8%;

[0031] 3) Pressing the dried material in the step 2), and separating the oil residue to obtain edible oil.

[0032] The invention softens the oil-pressing raw materials to obtain softened materials. In the present invention, the raw material for oil extraction is preferably peanut, rapeseed or soybean, more preferably peanut. In the present invention, the sources of the peanuts, soybeans and rapeseeds are not particularly limited, and conventional commercially available products in this field can be used. In the present invention, the softening method is preferably steam softeni...

Embodiment 1

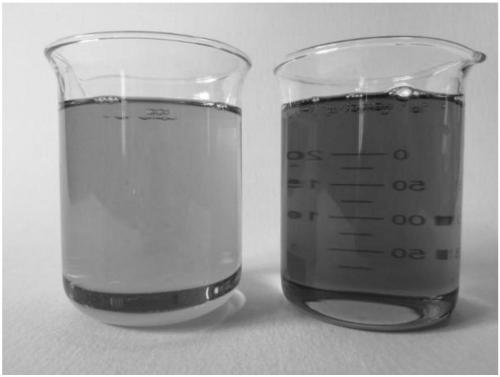

[0040] Adopt steam that the peanut is softened for 5min to make the moisture content of the peanut be 12%, and dry the softened peanut in a microwave drying equipment (the power during microwave drying is 20kw, and the temperature is 100° C.), so that the moisture content of the peanut after the microwave is 8%. Squeeze the microwaved peanuts, settle naturally, separate the oil residue, add 0.5% water and 1.2‰ montmorillonite to the separated oil, stir at 15r / min for 2h until the oil temperature drops below 30°C , adding 0.5% perlite to filter to obtain a strong flavor edible oil.

Embodiment 2

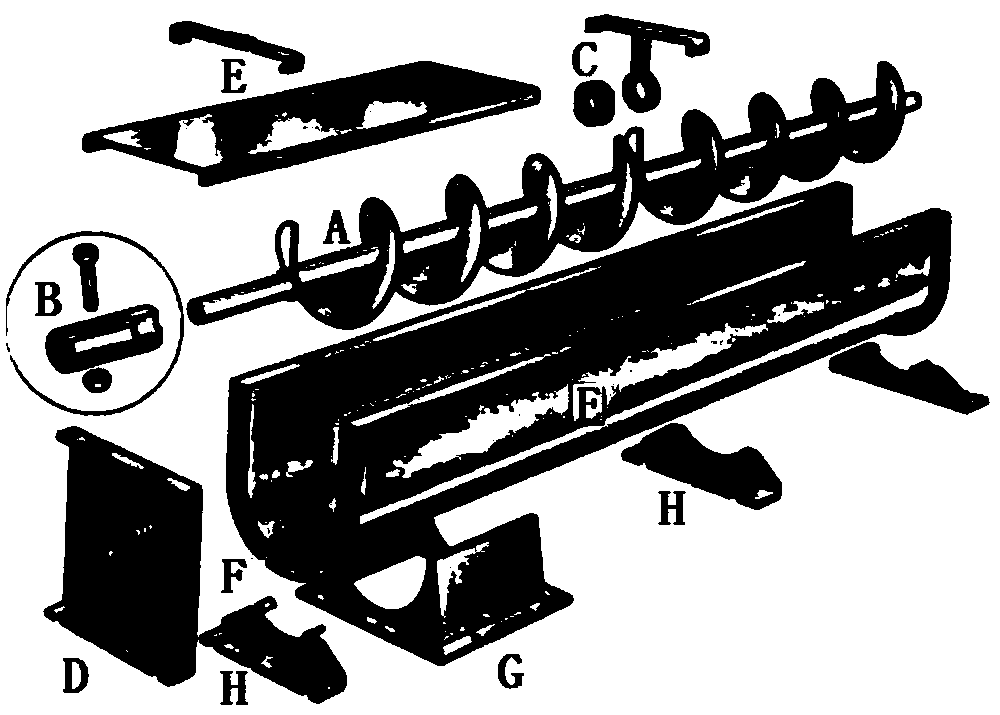

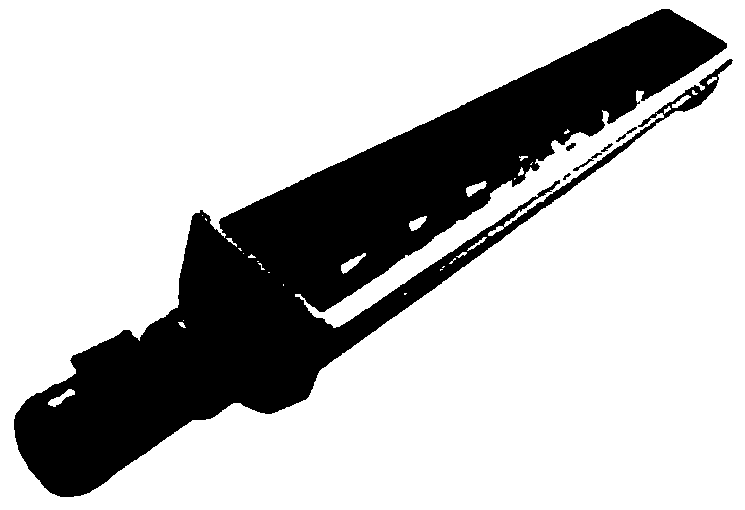

[0042]Peanuts are transported to the auger with a steam heating device to soften the peanuts for 30min, so that the water content of the peanuts is 17%, and the softened peanuts are transported to the microwave drying equipment for drying, (power during microwave drying is 200kw, Temperature is 140 ℃), and the moisture content of the peanut after microwave is 5%. Squeeze the microwaved peanuts, filter them with a filter to separate the oil residue, add 1.5% water and 0.8‰ montmorillonite to the separated oil, stir at 30r / min for 3h until the oil temperature drops to 30°C In the following time, add 2% diatomaceous earth to filter to obtain Luzhou-flavored edible oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com