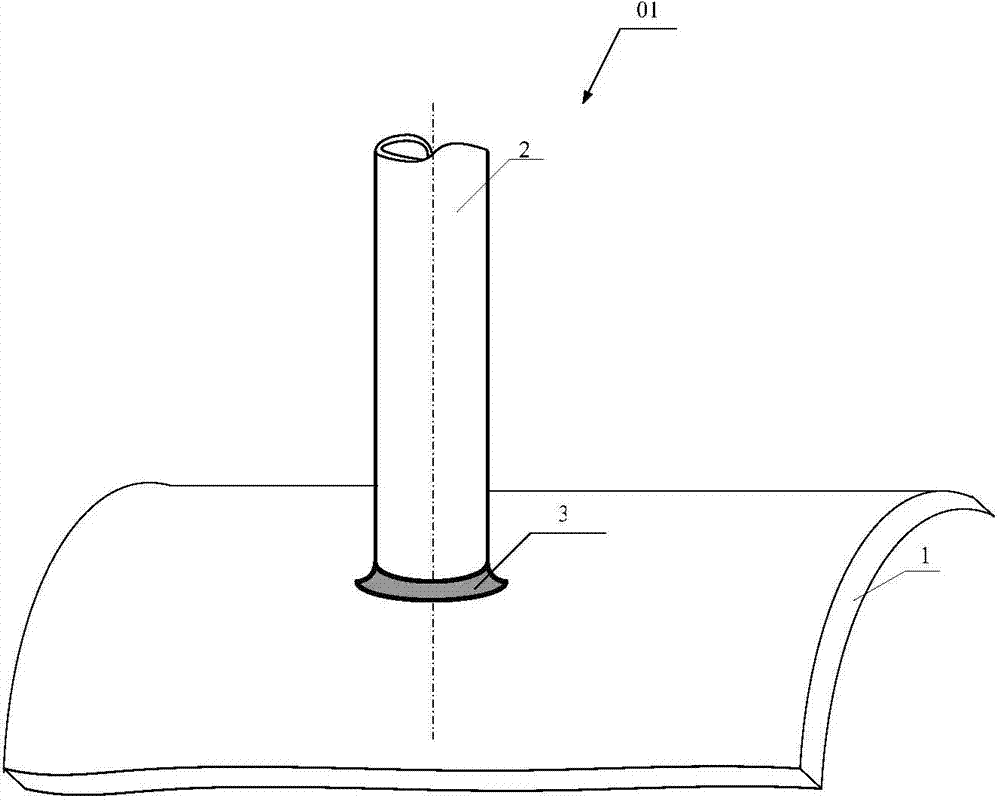

Local postweld heat treatment method of stub tube fillet joint

A technology for post-weld heat treatment and fillet joints, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as joint scrapping and material performance damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

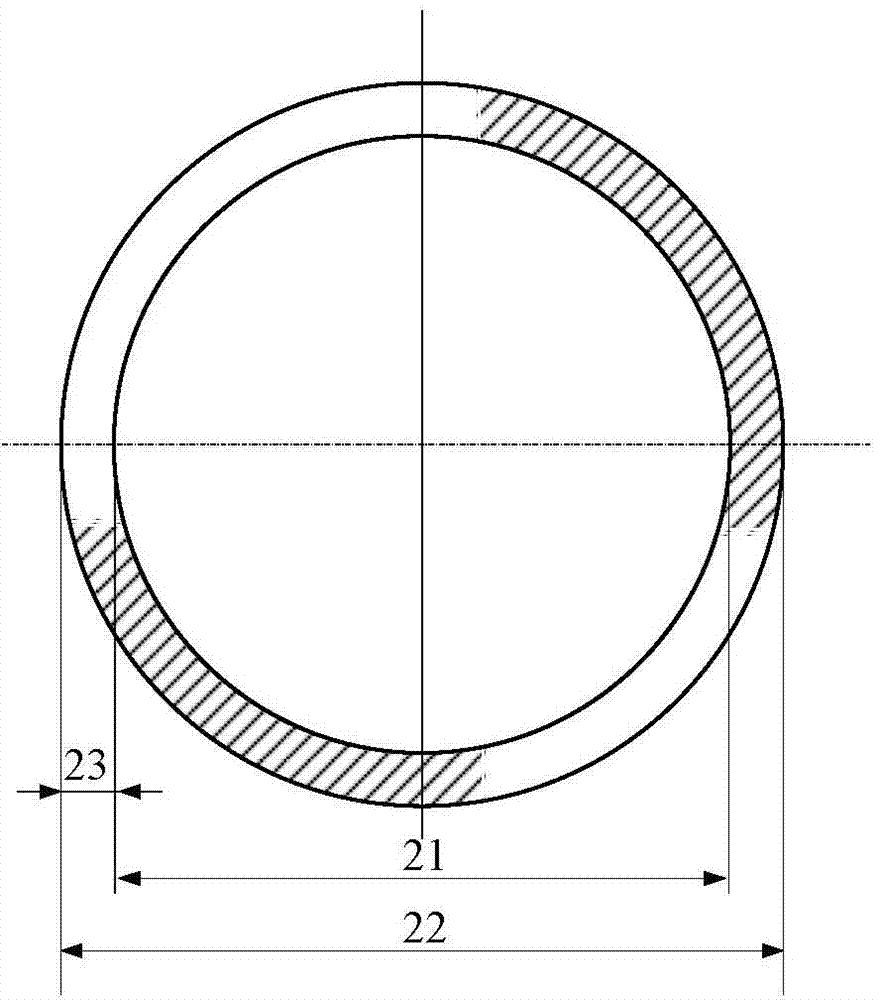

[0076] A pressure vessel cylinder is made of BHW35, with an outer diameter of 1800mm and a wall thickness of 95mm. There is a corner joint on it. The material of the joint seat is 20G, and the specification is OD273×22(mm). The welding repair process requires local post-weld heat treatment for the fillet joint. The constant temperature of the heat treatment is 600°C, the heating and cooling rate is 300°C / h, and the heating width on the cylinder during heat treatment is three times the wall thickness of the cylinder.

[0077] Using the method of the present invention to carry out local post-weld heat treatment on the fillet joint of the connecting pipe seat, the specific implementation steps are as follows:

[0078] (1) Calculation and selection of heating power

[0079] According to the requirements of the post-weld heat treatment process, the minimum power required for heating on the cylinder is calculated to be 17kW. With the center of the nozzle seat as the center, within ...

Embodiment 2

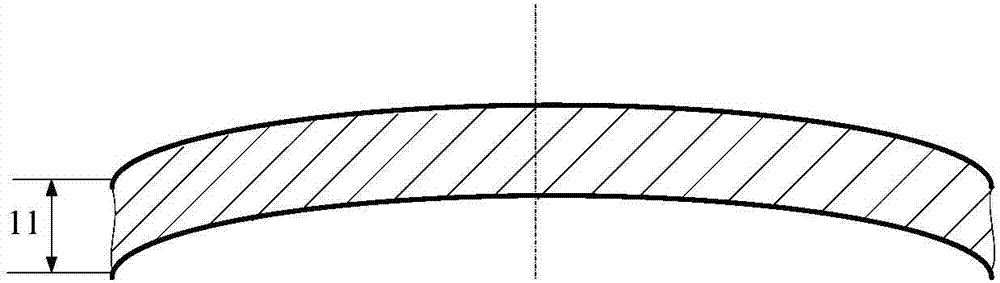

[0091] There is a fillet weld seam on the head of a container that requires local post-weld heat treatment after repair. The material of the head and the connecting pipe is 12Cr1MoVG, the outer diameter of the head is 828mm, and the wall thickness is 82mm; the outer diameter of the connecting seat is 347mm, and the wall thickness is 40mm. The welding process requires post-weld heat treatment for the fillet joint. The post-weld heat treatment process requires a constant temperature of 720°C, a heating and cooling rate of 75°C / h, and a heating width of 164mm that is twice the wall thickness of the head.

[0092] Using the method of the present invention to carry out local post-weld heat treatment on the fillet joint of the connecting pipe seat, the specific implementation steps are as follows:

[0093] (1) Calculation and selection of heating power

[0094] According to the requirements of the post-weld heat treatment process, the minimum power required for heating the head sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com